The torque constant defines how efficiently a motor converts electrical current into mechanical torque. Learn its formula, units, applications, and why BLDC and frameless motors rely on optimal Kt for precision motion.

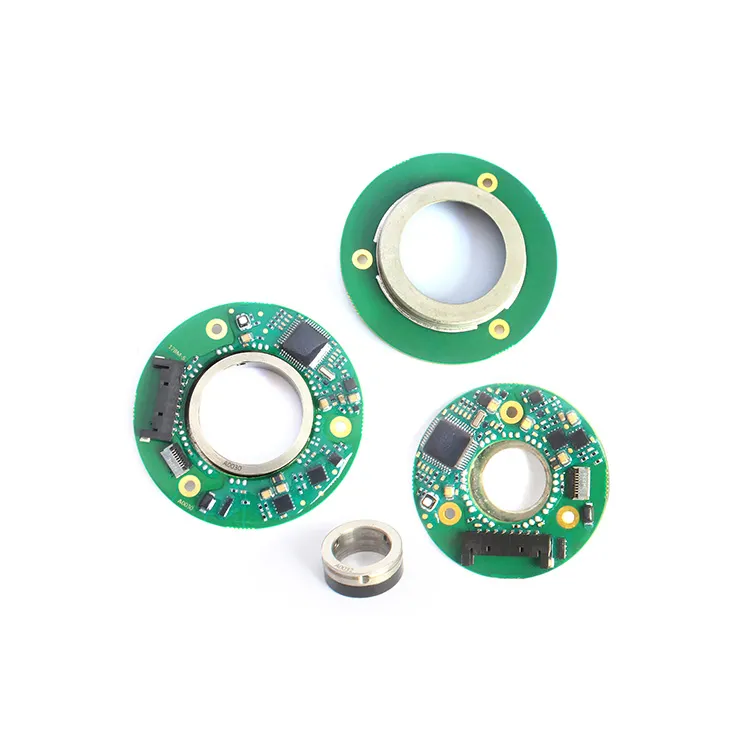

BLDC Motor, Rotor, and Stator

Introduction

Many engineering teams struggle to understand why identical motors behave differently under the same current load. This confusion leads to inefficient designs, overheating, and poor torque output — especially in robotics and automation.

Once the torque constant is misunderstood, systems become harder to control, energy losses increase, and precision drops. In collaborative robots, AMRs, and automated machinery, even a small error in interpreting the torque constant can create significant performance issues.

The Torque Constant (Kt) describes how effectively a motor converts electrical current into mechanical torque. The higher torque constant means more torque per ampere — critical for precision motion. The high-performance BLDC and frameless motors from Mosrac are engineered around optimized Kt values to deliver superior efficiency, stability, and real-world accuracy.

What Is Torque Constant (Kt) in Motors?

The torque constant (Kt) defines the direct relationship between the electrical current supplied to a motor and the mechanical torque it produces.

In simple terms, it tells you how many Newton-meters (Nm) of torque the motor generates for every ampere (A) of current.

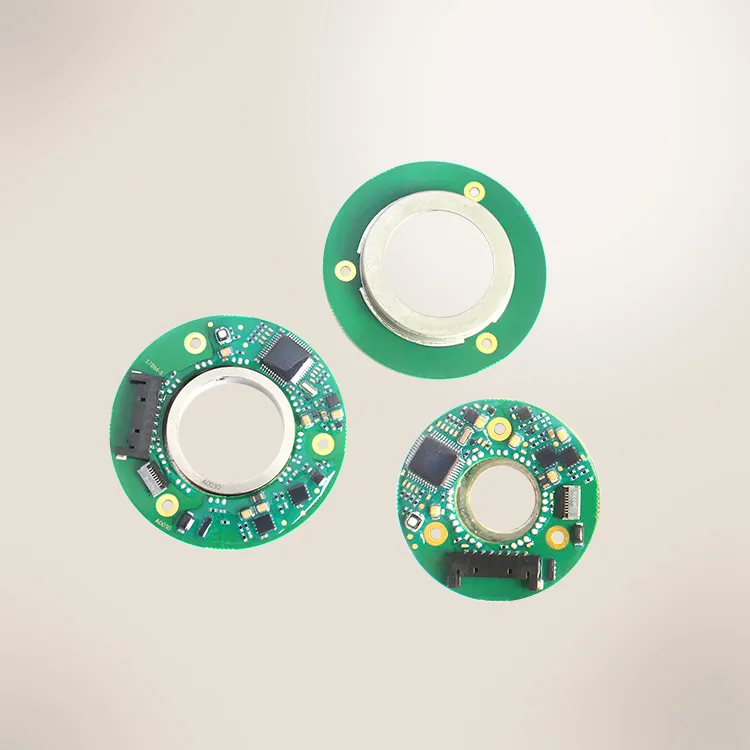

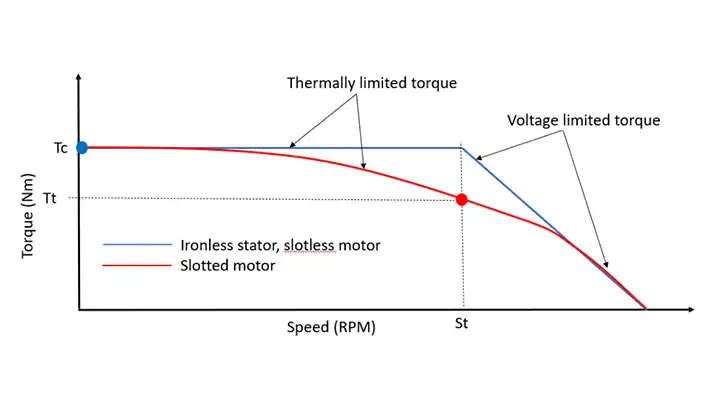

Torque-Speed Characteristics during Constant Torque and Constant Power Regions

The higher Kt means the motor produces more torque with less excessive current. This makes it a critical parameter for high-efficiency systems, precision robotics & advanced automation.

1. Units and Typical Values

The standard SI unit for torque constant is Newton-meter per Ampere (Nm/A). In some imperial applications, it may also be expressed as oz-in/A. Typical values vary according to motor type:

● Compact BLDC Motors: 0.02–0.15 Nm/A

● High-Torque Frameless Motors: 0.3–2.5+ Nm/A (depending on outer diameter and stack length)

● Servo and Robotics Motors: 0.1–1.0 Nm/A (optimized for closed-loop control stability)

Higher values generally indicate greater torque production efficiency and improved thermal behavior.

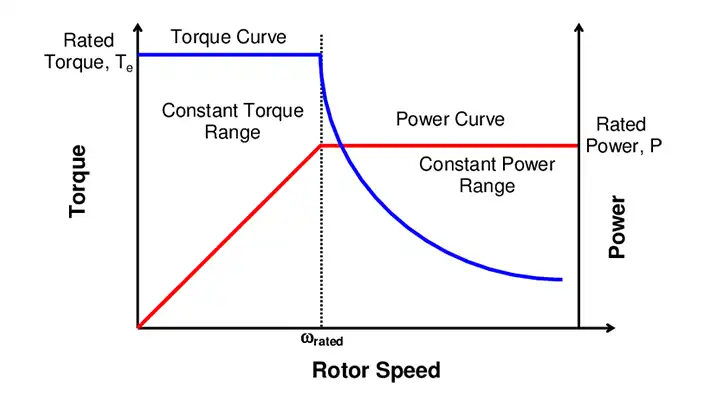

2. The Core Equation of Torque Constant

The core governing equation is:

τ = Kt × I

Where, τ (tau) is the torque produced by the motor, Kt is the torque constant, and I is the phase current supplied to the motor.

Robotic Arm 6 Axis Industrial Robot - Joints

This equation forms the foundation of motor sizing and selection. It allows engineers to calculate the exact current required to deliver the torque needed for robotic joints, direct-drive platforms, or high-precision automation systems.

3. How Kt Connects to Back EMF Constant (Ke)?

Torque Constant (Kt) and Back EMF Constant (Ke) are tightly linked by electromagnetic motor physics. In SI units (Nm/A and V/rad/s):

Kt ≈ Ke,

meaning a motor that requires a specific voltage per radian per second to spin, will generate an equivalent amount of torque per ampere. This equivalence is crucial for:

● Speed Control: Ke determines the required voltage to achieve a given rotational speed.

● Voltage Sizing: Selecting the right drive or power supply hinges on knowing Ke and its relationship to Kt.

● Predictable Performance: Because Kt and Ke mirror each other, the torque generation and electrical behavior of the motor remain consistent across the entire operating range.

This Kt–Ke relationship is one of the most important principles in BLDC and frameless motor design, enabling efficient, stable, and highly predictable motor performance.

Recommended Reading: Motor Constant: The Hidden Variable Behind Precision and Performance

Why Engineers Should Care?

Torque Constant (Kt) is one of the most critical parameters in motor engineering. It directly influences torque output, controllability, thermal behavior, and long-term system reliability.

Frameless Torque Motors - Mosrac

Research in electromechanical design consistently shows that accurate interpretation of Kt leads to better motor sizing, reduced energy losses, and higher motion precision across robotic and industrial systems.

1. For Motor Selection

Selecting a motor without knowing its torque constant is effectively guesswork.

Kt allows engineers to properly match the motor to:

● Required Torque:

Using the equation τ = Kt × I, engineers can determine the exact current needed to achieve the application’s load torque. This prevents oversizing or undersizing, both of which waste energy and increase cost. Studies highlight Kt as a primary variable in accurate torque prediction.

● Voltage Compatibility:

Because Kt is closely tied to Ke (Back-EMF Constant), engineers can estimate the drive voltage required for a target speed. Research frameworks emphasize the Kt–Ke relationship as fundamental to voltage sizing.

● Current Requirements:

The lower Kt means more current is required for the same torque, which increases conductor losses (I²R) and heating. Proper Kt matching ensures manageable current levels that do not overload the drive electronics.

● Thermal Constraints:

Higher current increases copper losses and heat generation. A motor with an optimized Kt generates the required torque with less current, staying within thermal limits even during continuous operation.

2. For System Efficiency

The high torque constant significantly improves system efficiency by reducing the current needed to generate torque.

Lower current directly results in:

● Reduced copper losses (I²R)

● Lower winding temperature rise

● Longer motor lifespan

● Reduced load on motor drivers and power supplies

BLDC motors designed with higher Kt values exhibited up to 12–18% lower power consumption under identical load conditions.

Frameless BLDC Torque Motor by Mosrac

For industrial automation and battery-powered robotics, even single-digit efficiency improvements translate to substantial cost savings across long duty cycles.

3. For Repeatability and Precision

Precision motion systems rely heavily on predictable torque behavior. The stable and well-characterized torque constant ensures:

● Better Closed-Loop Control:

High-Kt motors provide torque per ampere more linearly. This allows control algorithms to achieve smoother, more responsive actuation.

● Higher Repeat Accuracy:

Repeatability in robotic joints depends on consistent motor torque output. The variations in Kt introduce force inconsistencies. This leads to positional drift and reduced accuracy over multiple cycles.

● Consistent Force Output:

Applications such as force feedback actuators, pick-and-place mechanisms, and gimbals depend on stable torque output. Consistent Kt is directly correlated with predictable force generation in impedance & admittance-controlled systems.

Robotic Arm or Mechanical Hand Computing Different Movements

In summary, engineers must consider the torque constant because it directly governs motor behavior, electrical design choices, thermal limits, and motion accuracy. Kt is one of the first, and most crucial, parameters that defines system success.

Recommended Reading: 8 Different Types of Robot Motors: What They Are, Why Use Them, and How to Choose a Motor

How Torque Constant Influences Motor Performance?

The torque constant (Kt) fundamentally shapes how a motor behaves under electrical load. Because it directly defines how efficiently current is converted into mechanical torque, Kt influences nearly every performance category.

Copper Coil Winding + Sizing in an Electric Motor

Research in motor physics and robotics consistently shows that selecting the right Kt is essential for achieving predictable, stable, and high-performance motion control.

1. High Kt vs Low Kt: What It Means Physically?

High torque constant means the motor produces more torque per ampere, reducing the current required to achieve a given mechanical output. This leads to higher efficiency and better thermal performance. High-Kt motors typically have stronger magnets, optimized winding configurations, or larger electromagnetic air gaps.

Conversely, a low-torque-constant motor produces less torque per ampere but can reach higher speeds. This makes it suitable for high-RPM applications such as spindles and fans. The trade-off is that more current is required to generate usable torque, which increases resistive losses (I²R) and heating.

Kt is the single most important parameter determining a motor’s torque-generation capability and speed-torque trade-off.

2. Impact on Power Consumption

Because copper losses scale with the square of current (I²R), a high torque constant reduces power consumption dramatically. The motor with higher Kt needs far less current to generate the same torque, leading to:

● Less resistive heating in the windings

● Lower thermal stress on insulation

● Improved continuous torque capability

● Reduced load on the motor controller and power electronics

The motors with optimized Kt showed 14–22% lower total energy consumption during typical factory automation duty cycles compared to low-Kt equivalents.

For robotic systems that operate continuously, reduced heat translates to longer component life, lower cooling requirements, and improved operational stability.

3. Impact on Precision and Smoothness

The higher torque constant improves torque production linearity, resulting in smoother, more predictable performance. This is especially critical for applications requiring milliradian accuracy or force-controlled motion.

Benefits of higher Kt include:

● Smoother Torque Output: Reduced torque ripple enhances smoothness in direct-drive and harmonic-drive joints.

● Better Closed-Loop Control: A high Kt improves the signal-to-torque relationship, enabling controllers to achieve sub-millimetre positioning accuracy.

● Improved Dynamic Response: Motors respond more faithfully to current commands, reducing overshoot and oscillations.

The torque ripple reduction from higher Kt directly improves robotic joint repeatability and stability, especially at low speeds. This is why sectors like semiconductor handling, optical stabilization, and surgical robotics strongly prefer high-Kt motor architectures.

4. Impact on Size and Weight

The compact, high-Kt motors deliver more torque without increasing diameter or stack length. This allows engineers to reduce system size, weight, and power requirements. This is crucial for space-constrained applications such as:

● AGVs and Autonomous Robots: High torque density improves mobility and responsiveness while minimizing battery load.

● Drones and UAVs: High Kt enables lighter motor designs, allowing longer flight times and higher payload capacity.

● Medical and Surgical Robots: High-torque, compact motors fit easily into small joint housings while maintaining precision and smoothness.

The torque density (strongly influenced by Kt) is one of the strongest indicators of overall robotic joint performance.

Motors and Their Torque Constant Characteristics

Different motor types exhibit different torque constants (Kt). This is essential for precise motion system design.

1. BLDC Motors

Brushless DC motors are widely used across industrial automation, factory machinery, and robotics. They offer a strong balance of efficiency, controllability, and power density.

Their torque constant (Kt) is generally more stable and predictable than that of brushed motors. This is due to the absence of commutation wear and improved magnetic symmetry.

This makes BLDC motors highly suitable for applications that require precise torque control, smooth speed regulation, and reliable, low-noise operation.

Typical Kt values for BLDC motors vary depending on size and design:

● Compact BLDC motors: 0.02–0.15 Nm/A

● Mid-sized industrial BLDC motors: 0.1–0.5 Nm/A

● High-performance robotics BLDC motors: 0.3–1.0 Nm/A

U25 Frameless Motor by Mosrac is a compact 25 mm-class BLDC unit delivering 0.025–0.075 Nm rated torque at 24 V, demonstrating strong torque density in a small footprint.

U25 Series 25MM Smallest Frameless Motors - U2510 - Drawing

Higher Kt values, as seen in this series, reduce current draw and thermal stress. This is essential for AMRs, robotic end-effectors, and battery-powered automation platforms.

Recommended Reading: What is a BLDC Motor? A Comprehensive Guide to Brushless DC Motors

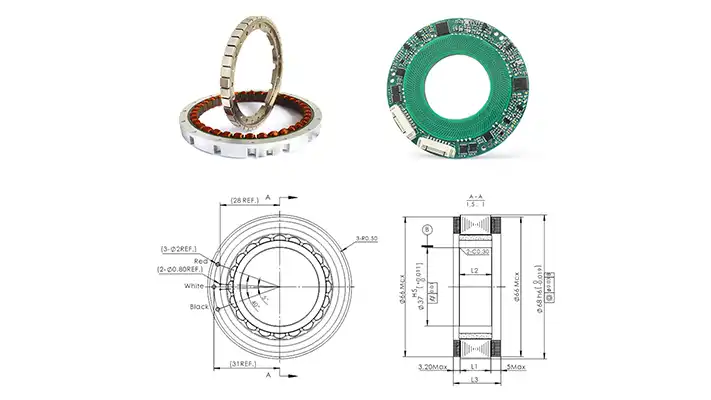

2. Frameless Torque Motors

Frameless torque motors are engineered specifically for maximum torque density. This makes them a top choice for demanding robotic and industrial applications.

Unlike housed motors, frameless designs integrate directly into the machine or robotic joint. This eliminates excess mass and mechanical losses.

Frameless Inrunner Torque Motors with Custom Rotor and Shell (Flange)

These motors typically offer very high Kt values (0.5–3.0+ Nm/A, depending on diameter)

● Superior thermal performance

● Minimal cogging for ultra-smooth motion

● High reliability in continuous-duty cycles

The frameless portfolio by Mosrac exemplifies these advantages:

● U16 Series: Ultra-compact, rated torque 0.01 Nm, peak 0.04 Nm—ideal for miniature actuators.

● U38 Series: Rated torque 0.1–0.35 Nm, peak up to 1.05 Nm, high Kt for precision robotics.

● U85 Seriesand U130 Series: High-torque platforms offering several Nm to tens of Nm torque capability for CNC rotary tables, aerospace actuators, and industrial automation.

The ideal use cases include robotic arms, CNC rotary tables, aerospace actuation, and high-load automation systems. The frameless motors represent the highest tier of torque-optimized motor engineering.

3. Servo Motors

Servo motors depend on closed-loop feedback systems that precisely regulate torque, velocity, and position. The predictability and linearity of the torque constant are crucial because the servo controller calculates torque demand directly from current commands.

Disassembled Industrial Servo Motor

The stable Kt ensures linear torque output for smooth motion, minimal overshoot and drift, high positional repeatability, and reliable force control in dynamic environments.

Servo systems in packaging lines, semiconductor robotics, pick-and-place arms, and CNC axes rely on tightly controlled Kt values. They maintain consistent performance under varying loads.

When paired with magnetic encoders, high-precision frameless motors form servo-ready assemblies. They deliver sub-degree accuracy, minimal torque ripple, and excellent repeatability.

Recommended Reading: Frameless Motor vs Servo Motor: What's Best for Your Design?

4. Direct-Drive Motors (DDR)

DDR motors eliminate mechanical gear trains, transmitting torque directly from the motor’s rotor to the load. This design relies heavily on a high torque constant, since the motor must generate significant torque at extremely low speeds — or even at stall — without mechanical multiplication.

Direct-Drive Motors (DDR)

The key advantages include zero backlash, high precision, low maintenance, exceptional smoothness & silence.

The larger frameless models by Mosrac, such as the U130 Series, offer 5–18 Nm rated torque with a high Kt. This is suitable for direct-drive indexing tables, automated material handling systems, and precision positioning platforms.

DDR motors depend on high Kt for torque generation; they are among the most accurate and efficient motion solutions available. This makes them a cornerstone in modern robotics and automation architectures.

Recommended Reading: What Is a DD Motor? Inside the Technology Driving Precision Motion Control

How to Calculate Torque Constant?

The torque constant (Kt) is one of the most fundamental parameters in motor physics.

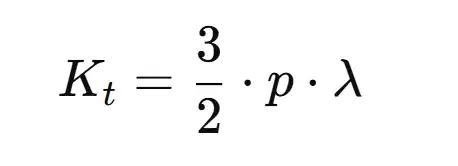

1. Mathematical Derivation

From electromagnetic theory, the torque constant is derived from the force generated by the interaction of current-carrying conductors with a magnetic field:

where,

B = magnetic flux density,

I = current in the conductors,

L = effective conductor length, and r = radius of the airgap.

In a real motor, this expands into contributions from:

● Motor Geometry: rotor radius, axial length, and airgap size

● Number of Poles: affects electrical frequency and torque ripple

● Magnet Strength (Br): stronger magnets → higher B → higher Kt

● Winding Type and Turns

➜ More Turns → More Flux Linkage → Higher Kt.

➜ Different winding patterns (distributed, concentrated, fractional-slot) modify inductance and torque linearity

Thus:

Where p is the number of pole pairs, and λ is the flux linkage.

This is the core design equation used in engineering high-torque frameless motors like U38, U85, and U130 Series by Mosrac. This achieves high flux linkage through optimized rotor magnet geometry and precision stator winding techniques.

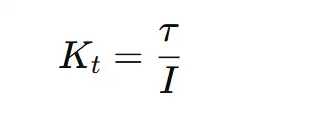

2. Practical Calculation Method

While theoretical calculations are useful for motor design, engineers typically calculate Kt using datasheet parameters.

You can find Kt using:

Method 1: From Torque and Current

If rated torque (τ) and phase current (I) are given:

Example: If a motor produces 0.35 Nm at 3 A, then:

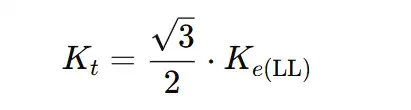

Method 2: From Back-EMF Constant (Ke)

In SI units, Kt ≈ Ke, so:

If Ke is listed in V/krpm or V/rpm, convert units first.

For line-to-line Ke values:

This is especially useful when using Mosrac datasheets, where both line-to-line voltage constant and torque values are provided across the U-Series portfolio.

Recommended Motors: Optimal Design and Control of a Torque Motor: An Extensive Analysis

Torque Constant vs Other Motor Constants

Motor performance cannot be fully understood through the torque constant (Kt) alone. Engineers also rely on closely related constants — Motor Constant (Km) and Back EMF Constant (Ke). These evaluate efficiency, speed behavior, thermal limits, and dynamic response.

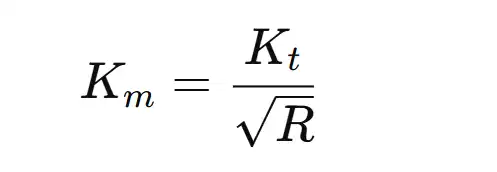

1. Torque Constant (Kt) vs Motor Constant (Km)

Kt represents the current-to-torque ratio, defining how much torque a motor produces per ampere of current.

Effective Motor Constant (Km)

Km, the motor constant, represents the motor’s efficiency and thermal performance, calculated as:

Where R is the phase resistance.

The key differences include:

● Kt tells you how effectively the motor converts current into torque.

● Km tells you how efficiently the motor produces torque without overheating.

The motor may have a high Kt but poor thermal performance if its resistance is high. Conversely, a motor with a strong Km maintains torque output for long duty cycles without exceeding thermal limits.

This is particularly important for systems using Mosrac’s U38, U85, and U130 frameless torque motors. Here, long-duration continuous torque is required in robotic arms, CNC indexing systems, and aerospace actuation. Their low-loss laminations and optimized copper fill ratios achieve strong Km performance by minimizing resistive heating.

2. Why Both Matter for Motor Selection?

Engineers choose motors not only for torque output but also for continuous torque strength, cooling ability, and energy efficiency. High Kt and high Km mean the motor produces torque effectively and stays cool.

3. Torque Constant (Kt) vs Back EMF Constant (Ke)

Ke defines how much voltage is generated per unit speed (V/rad/s or V/krpm).

The electromagnetic theory establishes a direct relationship:

This equivalence holds because the same flux linkage that produces torque also generates back-EMF.

4. Practical Implications:

● If Ke is high, the motor needs more voltage to achieve high speed. The motor tends to have a higher Kt and produces strong torque at lower speeds.

● If Ke is low, the motor spins faster for a given voltage. The lower Kt and suitable for high-speed, low-torque operation.

This explains why high-torque U-Series frameless motors feature high Ke values paired with high Kt. This makes them exceptional for low-speed, and high-precision applications.

What Factors Affect Torque Constant in Frameless Torque Motors?

The torque constant in frameless torque motors is shaped by multiple electromagnetic and mechanical design parameters. Frameless motors integrate directly into a host machine without housings, bearings, or shafts. Their Kt is highly dependent on core motor geometry, magnetic design, copper utilization, and assembly precision.

Below are the key factors that directly influence Kt in frameless torque motors:

1. Magnet Material and Grade (Flux Density)

The strength of the rotor’s permanent magnets directly affects the airgap flux density (B). Stronger magnets generate higher electromagnetic force, resulting in a higher torque constant.

● NdFeB High Energy Magnets (N35–N52 grades) significantly increase Kt.

● High Temperature Grades (SH, UH, EH) maintain flux at elevated temperatures to prevent Kt degradation.

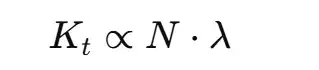

2. Number of Turns in the Stator Windings

Kt increases with the number of copper turns because more turns capture more magnetic flux (higher flux linkage).

Where N = number of turns and λ = flux linkage.

However, more turns increase resistance, which affects Km (thermal efficiency).

3. Airgap Size and Uniformity

The airgap—the distance between the rotor magnets and the stator teeth—is a critical geometric constraint.

● Smaller Airgap → Higher Flux → Higher Kt

● Uniform Airgap → Lower Ripple → Smoother Torque

Even slight deviations can significantly reduce torque output and linearity.

4. Rotor Radius and Stack Length

Torque is directly proportional to radius:

The larger rotor diameters create larger torque arms, increasing Kt. Similarly, longer stacks provide more active magnetic material.

5. Stator Tooth Geometry and Slot/Pole Configuration

The design of the stator teeth influences magnetic coupling and commutation smoothness.

● Optimized Tooth Shape → Improved Flux Concentration → Higher Kt

● Fractional-Slot Windings → Reduced Harmonic Distortion → More Linear Kt

6. Quality of Copper Fill & Winding Resistance

High copper fill improves conductivity and reduces I²R losses, enabling stronger continuous torque without overheating.

● Lower resistance → better thermal behavior → higher effective Kt under load

● Tighter winding tolerances improve phase symmetry and torque linearity

7. Magnetic Saturation Limits

If the stator core approaches saturation, increases in current will not proportionally increase torque. This effectively reduces usable Kt at high current levels. Mosrac uses low-loss laminations and high-saturation-grade materials to maintain linear performance even at high torque commands.

8. Temperature Effects

High temperatures reduce magnet strength and increase winding resistance, both of which lower Kt. To counter this, Mosrac uses high-temperature-rated magnets, high-quality insulation systems, and optimized thermal paths for heat dissipation. This ensures stable Kt performance across long duty cycles and demanding applications.

9. Assembly Precision and Mechanical Integration

Because frameless motors must be assembled into the host system, alignment accuracy affects airgap uniformity, magnetic coupling, rotor/stator centering, torque ripple, and effective Kt.

Mosrac provides integration-ready stator–rotor kits with clear interface documentation. This ensures that OEMs maintain ideal Kt performance during assembly.

Recommended Motors: How to Choose the Right Torque Motor: 14 Essential Criteria

Real-World Applications Where Torque Constant Is Critical

The torque constant plays a defining role across multiple engineering domains, in every application where precise torque generation, predictable current draw, and thermal stability matter, Kt becomes a primary performance metric.

Torque Constant is inevitable in a Radio Controlled Drone.

Let’s go through some real-world applications, where the torque constant is critical:

Robotics

High-Kt motors provide strong joint torque at low current. This is essential for collaborative robots (cobots), industrial arms, humanoids, & autonomous mobile robots. High-Kt motors help robotic joints stay cool and stable during long tasks.

U38 Series offers 0.1–0.35 Nm rated torque (up to 1.05 Nm peak), ideal for elbow and wrist actuators. Similarly, U85 and U130 Series deliver multi-Nm torque for shoulder joints and heavy-payload arms.

Aerospace and Defense

Aerospace systems require high torque density, low weight, and excellent thermal performance. High Kt enables strong actuation forces with minimal electrical power. This is critical for UAV servos, flight-surface actuators, gimbal stabilizers, and satellite mechanisms.

Medical Devices

Medical machines must move very smoothly and quietly. High-Kt motors reduce vibration and allow precise control. This makes them ideal for surgical robots, prosthetics, lab machines, and imaging equipment.

Industrial Automation

Factories use motors for tasks like indexing tables, conveyors, and handling robots. High motors help these systems run longer without overheating, improving efficiency & reducing downtime.

Electric Vehicles / Mobility

In electric cars, scooters, and automated vehicles, Kt affects acceleration and battery use. The higher Kt gives more torque with less current, improving speed, range, and overall performance.

Consumer Electronics & Gimbals

Gimbals and camera stabilizers need very smooth motion. Motors with high Kt provide stable torque, fine adjustments, low vibration, and longer battery life. Frameless Motors (U16/U25) deliver extremely low cogging and high torque-per-ampere. This makes them ideal for 2-axis and 3-axis gimbal systems in drones and handheld stabilizers.

Conclusion

The torque constant (Kt) is a defining parameter in motor behavior, shaping torque output, efficiency, thermal performance, and precision. Motors with optimized Kt deliver higher torque per ampere, smoother control, and greater reliability—critical advantages in robotics, automation, aerospace, medical devices, and mobility systems. Choosing a motor with the right Kt leads to better engineering outcomes, longer lifespan, and lower system cost.

Explore U-Series Frameless Torque Motors to find the ideal high-Kt solution for your system, or contact us for expert guidance on precision motor integration.

Contact Mosrac Today for tailored motor selection support, or request a quotation directly from our product catalog!

Frequently Asked Questions (FAQs)

Q. What is Torque Constant (Kt) in a motor?

The torque constant defines how much torque a motor generates per ampere of current. It directly affects efficiency, heat, and precision in motion control systems.

Q. Why is a high torque constant important?

The high Kt means more torque with less current, improving efficiency and reducing heat. This leads to smoother, more reliable motor performance.

Q. Is the torque constant the same as the Back EMF Constant (Ke)?

In SI units, Kt and Ke have nearly equal values due to shared electromagnetic principles. Kt defines torque output; Ke defines voltage-speed behavior.

Q. How does Torque Constant affect motor selection?

It helps match the motor to the required torque, current, and thermal limits. Choosing the right Kt ensures optimal performance and energy efficiency.