Discover how DD motors (Direct Drive Motors) eliminate gearboxes for ultra-smooth, high-precision motion control. Learn their working principle, advantages, and applications — and explore housed DD torque motors for superior performance!

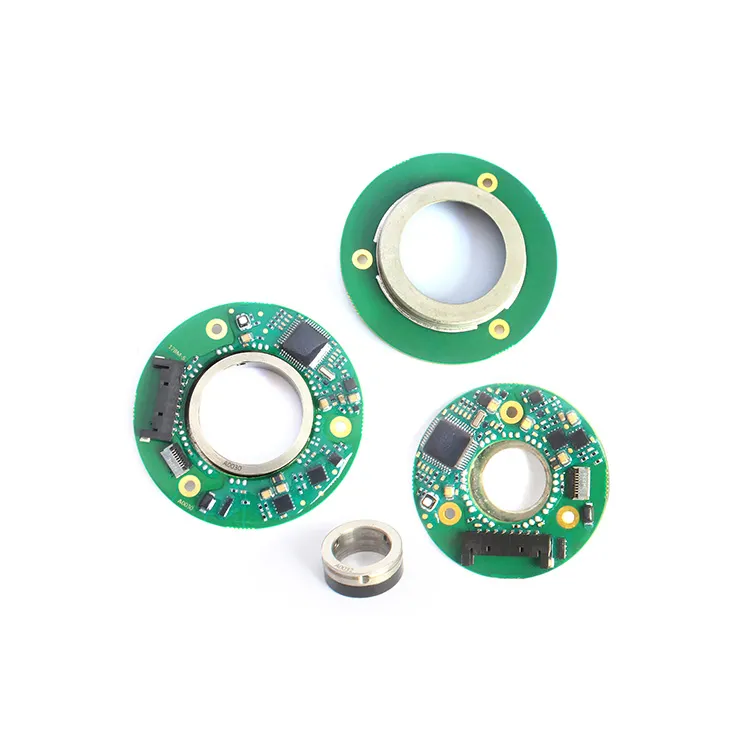

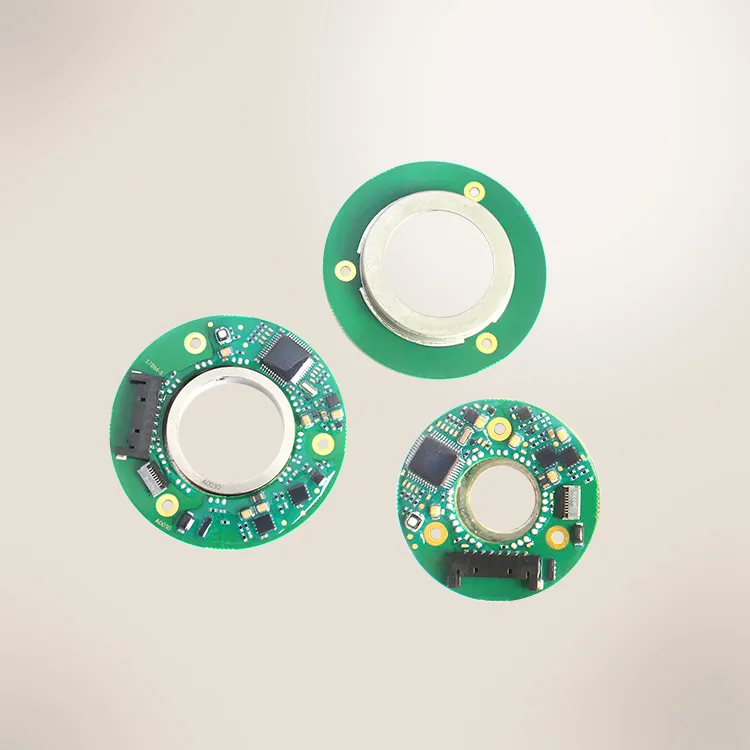

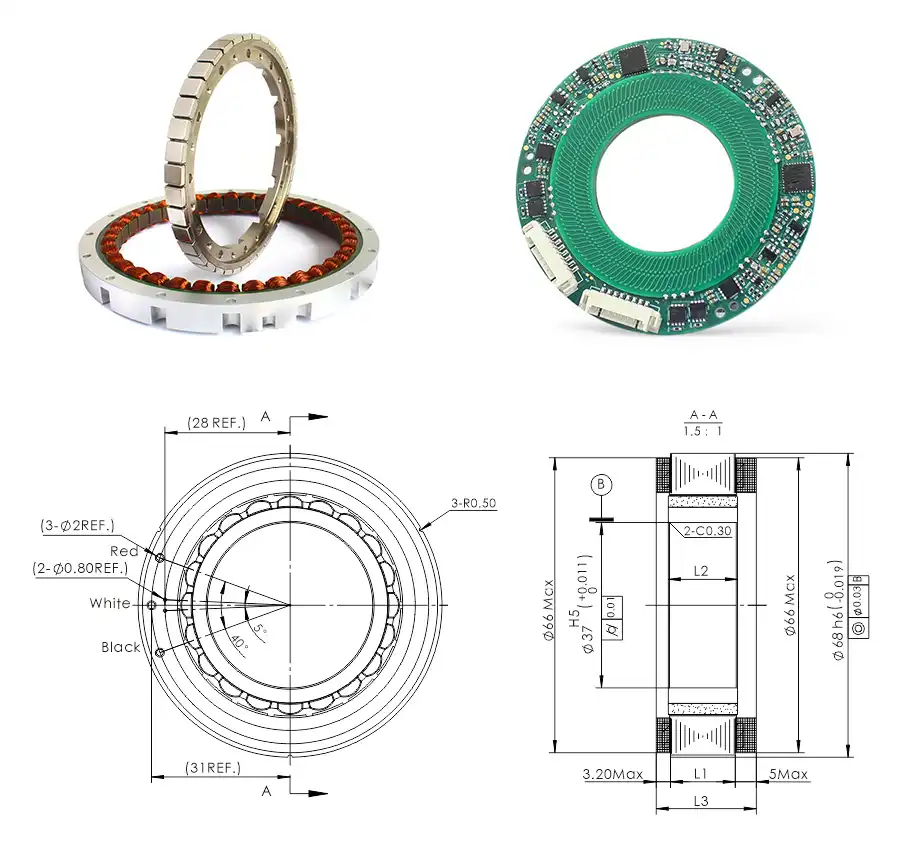

The Rotor & Stator of a Direct Drive (DDR) Motor

Introduction

In today’s world of robotics, automation, and semiconductor assembly, even the slightest inaccuracy can lead to costly downtime and defective products. Traditional servo + gearbox systems struggle with backlash, friction, and maintenance, limiting performance in high-precision environments. That’s where the DD Motor (Direct Drive Motor) revolution begins!

By eliminating mechanical transmission, DD Motors transfers torque directly to the load, enabling smoother, quieter, and more accurate motion control. This breakthrough in precision motion control delivers unmatched efficiency and responsiveness.

We at Mosrac, specialize in high-torque, zero-backlash DD motor designs engineered for next-generation automation and robotics applications.

What Is a DD Motor?

✅ Definition and Core Concept

Direct Drive Motor (DD Motor) is an advanced type of electric motor designed to transmit torque directly to the load, without the need for gears, belts, or mechanical couplings. By eliminating intermediate transmission components, DD Motors removes sources of friction, backlash, and wear, resulting in exceptionally smooth and precise motion control.

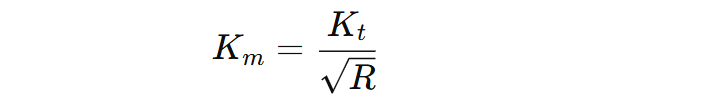

House Direct Drive Motor

Unlike conventional servo systems that rely on gearboxes to amplify torque, Direct Drive Motors generate high torque at low speeds through optimized electromagnetic design. This allows the motor shaft to connect straight to the driven mechanism, such as a rotary table or robotic joint, minimizing motion errors and latency.

In essence, DD Motors combine torque motor design with high-resolution feedback systems, making them ideal for applications that demand sub-micron accuracy, such as robotics, semiconductor wafer handling, and CNC indexing tables.

✅ Fundamental Components

1. Stator and Rotor Construction

At the heart of every DD Motor lies a stator wound with copper coils and a rotor embedded with high-energy permanent magnets. When current flows through the stator windings, it creates a rotating magnetic field that interacts with the rotor’s magnetic poles, producing torque directly on the output shaft.

◉ Advanced materials, such as NdFeB magnets and laminated silicon steel, enhance torque density and reduce eddy current losses.

◉ The absence of gears ensures low cogging torque, allowing ultra-smooth rotation even at low speeds.

2. Position Feedback Systems

Precision in Direct Drive Motors depends heavily on encoder technology. Integrated magnetic encoders or optical encoders continuously monitor rotor position, providing high-resolution feedback to the control system.

◉ Magnetic encoders offer robust performance in harsh environments and are well-suited for housed DD motors, ensuring durability and accuracy.

◉ Optical encoders provide extreme resolution for ultra-fine motion, commonly used in semiconductor and metrology applications.

3. Thermal Management Design

Because DD Motors operate with high continuous torque, effective thermal regulation is vital. Housed DD motor architecture integrates optimized heat dissipation channels, precision bearings, and thermal sensors for consistent performance and reliability.

◉ The motor constant (Km), a measure of torque output per unit power loss is maximized through advanced thermal and electromagnetic design.

◉ This ensures efficient power conversion, extended motor lifespan, and stability during prolonged operation in high-duty cycles.

In short, Direct Drive Motors represent a fusion of electromagnetic precision, mechanical simplicity, and thermal intelligence. This enable engineers to achieve unparalleled motion accuracy, high torque density, and maintenance-free reliability in modern automation systems.

Recommended Reading: Motor Sizing Guide: How to Select the Right Motor for Optimal Performance

How Does a DD Motor Work?

✅ The Engineering Behind Direct Torque Generation

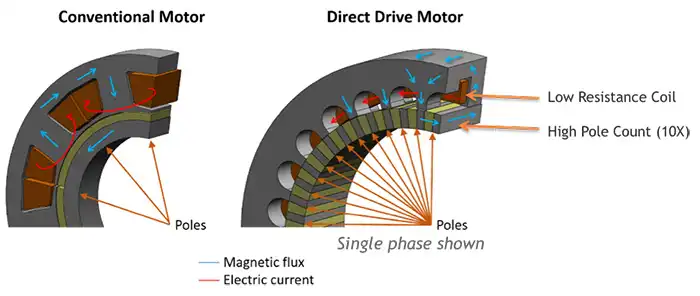

Direct Drive Motor (DD Motor) produces torque directly on the output shaft through the interaction between the the electromagnetic field in stator and the permanent magnets in rotor. When current flows through the stator windings, it generates a rotating magnetic field. This field engages the magnetized rotor, creating torque without the need for gears, belts, or other transmission elements.

Conventional Motor vs Direct Drive Motor; Source: Pumps & Systems

The absence of mechanical transmission components means there is no backlash, no compliance, and minimal friction, resulting in instantaneous response and exceptional motion precision. This direct torque generation also improves dynamic stiffness, allowing for rapid acceleration and deceleration, a critical factor in robotics, semiconductor automation, and CNC machinery.

In contrast to gear-driven systems, where torque passes through multiple interfaces, a DD Motor transmits energy at a one-to-one ratio, ensuring that every bit of electrical energy contributes to pure rotational motion. This is why DD Motors are known for their smooth, quiet operation and high torque density across low-speed ranges.

✅ Control Systems and Feedback Loops

The precision of a DD Motor relies heavily on its servo control loop, a closed-loop feedback system that continuously monitors and adjusts motor performance.

The core of this system are high-resolution encoders, which provide real-time position and velocity feedback to the controller. These encoders detect minute changes in rotor position and transmit them to the motor driver, ensuring sub-micron accuracy even during high-speed operations.

Servo amplifiers and motor controllers convert command signals into precisely modulated currents, synchronizing the stator’s magnetic field with the rotor’s position. This continuous correction process maintains motion feedback stability, eliminates torque ripple, and ensures maximum motor efficiency under varying loads.

Housed DD motors by Mosrac are fully compatible with advanced encoder systems and motion control solutions, offering seamless integration into industrial automation platforms. The result is a highly responsive, vibration-free drive system optimized for real-world precision tasks, from robotic joint actuation to semiconductor wafer positioning.

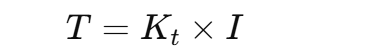

✅ Theoretical Insight (Intermediate Level)

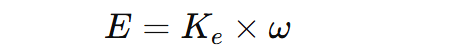

To fully understand DD motor performance, it’s essential to examine the key relationships between its electrical and mechanical constants:

◉ Torque Constant (Kt): Determines how much torque (T) is generated per ampere of current (I).

◉ Back EMF Constant (Ke): Represents the voltage generated per unit rotational speed (ω).

◉ Motor Constant (Km): A measure of overall motor efficiency, the ratio of torque output to power loss due to heating. R is the resistance here.

The higher Km values indicate greater thermal efficiency and improved power utilization, both key attributes of DD motor architecture by Mosrac.

Control methods such as Field-Oriented Control (FOC) and Direct Torque Control (DTC) are often employed to achieve high-precision torque regulation.

◉ FOC aligns the stator current vector with the rotor’s magnetic field, ensuring smooth and efficient torque production with minimal losses.

◉ DTC directly manipulates stator flux and torque, offering a fast transient response ideal for high-speed servo applications.

By combining accurate motion feedback, optimized torque constants, and real-time control algorithms, Direct Drive Motors achieve an unmatched balance of stability, responsiveness, and efficiency.

Recommended Reading: Design and Development of Robots: Integrating Motor Control

Why Engineers Choose DD Motors?

✅ Performance Advantages

Engineers across industries are increasingly adopting Direct Drive Motors (DD Motors) for one core reason — uncompromised precision. By eliminating the need for gears, belts, or couplings, DD motors deliver instant torque response and zero backlash, ensuring motion accuracy down to the sub-micron level. This makes them ideal for robotic arms, semiconductor wafer stages, and CNC rotary tables, where even the smallest mechanical play can lead to major positioning errors.

Direct Drive: a) Torque Motor, b) Direct Drive Rotary Table; Source: ResearchGate

The absence of gears also results in quiet, vibration-free operation, making DD motors perfect for environments where smooth motion and low noise are critical, such as medical imaging systems or optical alignment platforms. With fewer mechanical components, DD motors require virtually no maintenance, leading to lower operational costs and increased uptime. Their compact and integrated design allows for flexible installation, saving valuable space within motion assemblies while maintaining exceptional torque output.

✅ Technical Benefits

Beyond mechanical simplicity, DD Motors delivers superior engineering performance unmatched by conventional systems:

◉ High Torque-to-Weight Ratio: Advanced magnetic materials and optimized coil design allow DD motors to produce exceptional torque within compact footprints.

◉ Superior Thermal Stability: Integrated cooling pathways and optimized winding architecture maintain consistent performance under continuous operation.

◉ Excellent Repeatability: Direct coupling minimizes hysteresis, ensuring precise, repeatable positioning cycle after cycle.

◉ Extended Lifetime and Reliability: Fewer moving parts mean minimal wear, resulting in longer operational life and reduced downtime.

◉ Consistent Power Efficiency: Direct torque generation improves motor efficiency, reducing energy losses compared to gearbox-driven alternatives.

Incorporating housed DD torque motors ensures reliable motion control, outstanding thermal performance, and engineering precision. This supports modern automation, robotics, and semiconductor production environments, where every micron of motion matters.

Applications of DD Motors

✅ Industrial and Robotic Automation

In the field of industrial automation and robotics, Direct Drive Motors (DD Motors) have become the cornerstone of precision motion. Their ability to deliver instant torque response, zero backlash, and smooth, repeatable motion makes them ideal for robotic joints, semiconductor wafer handling systems, and automated inspection platforms.

In robotic systems, the direct coupling between the motor and the load allows for extremely accurate positioning, eliminating motion lag that occurs with gear-driven actuators. This enables robots to perform delicate assembly, pick-and-place, and micro-manipulation tasks with unmatched precision.

✅ CNC Machines and Indexing Tables

In CNC machining centers and indexing applications, DD Motors are redefining rigidity and responsiveness. Conventional servo systems often depend on mechanical gear reduction to achieve high torque — a process that introduces backlash and slows response times.

Two-Axis Rotary Indexing Tables; Source: Carl Hirschmann

By contrast, Direct Drive Motors transmit torque straight to the spindle or rotary table, producing instantaneous angular acceleration and smooth rotation without any mechanical compliance. This direct coupling drastically enhances positioning accuracy, surface finish quality, and machine throughput.

For indexing tables, DD Motors provide fast start-stop cycles, precise angular control, and zero maintenance requirements, making them ideal for high-speed machining, laser cutting, and tool calibration systems.

✅ Aerospace, Medical, and Testing Equipment

In industries where reliability and accuracy define success, DD Motors offer a performance advantage that mechanical systems cannot match.

In aerospace simulators, DD motors enable real-time motion feedback and smooth, continuous control, delivering lifelike pilot training experiences with zero motion lag. In medical robotics, they power surgical instruments and imaging systems, providing surgeons with precise, noise-free actuation critical for minimally invasive procedures.

In testing and metrology systems, DD motors provide stable, repeatable motion under extreme conditions, ensuring consistent measurement accuracy. Their low vibration profile, high thermal stability, and maintenance-free design make them ideal for laboratory-grade instrumentation.

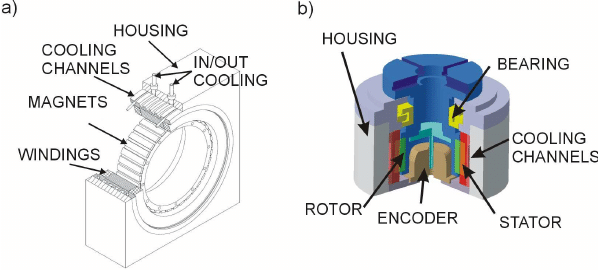

DD Motors vs Conventional Systems

✅ ROI and Long-Term Efficiency

While DD Motors has a higher upfront investment, its total cost of ownership (TCO) is significantly lower over time. The elimination of mechanical transmissions reduces maintenance frequency, energy losses, and system downtime; all of which contribute to greater long-term ROI.

In high-performance applications such as robotics, CNC machining, and semiconductor automation, downtime costs can exceed the savings from cheaper hardware. With Direct Drive Motors, engineers gain decades of stable performance, consistent torque output, and maintenance-free reliability, turning the initial investment into sustained operational efficiency.

Design Considerations for Selecting a DD Motor

✅ Key Parameters

1. Torque Requirement (Continuous & Peak)

Calculate worst-case load torque (friction + gravity + cutting/process torque) and add safety margin (10–30%).

◉ Continuous torque must exceed RMS load torque over the duty cycle.

◉ Peak torque must cover accelerations and transient shocks (typically 2–4× continuous).

2. Speed and Acceleration

Define maximum operating speed and required acceleration/deceleration to meet cycle time. Check back-EMF vs. bus voltage margin and verify that peak current×Kt delivers the target angular acceleration.

3. Inertia Matching

Aim for a load-to-motor inertia ratio in the 1:1 to 5:1 range for stiff, well-damped control (DD motors often tolerate higher ratios due to zero backlash). Consider adding virtual inertia via control only if bandwidth allows.

4. Encoder Resolution

Choose encoder counts that yield ≤1/10 of the smallest required positioning increment. High-resolution magnetic or optical encoders minimize quantization error and improve servo stiffness and low-speed smoothness.

5. Thermal Management

Verify continuous torque at the application’s ambient with adequate thermal paths (housing, flange conduction, forced convection if needed). Check coil temperature rise vs. insulation class and duty cycle to protect Km (motor constant) performance over time.

✅ Integration Tips

1. Mounting Alignment

Use precision pilot fits and flatness specs to prevent bearing preload. Align the rotor/load axes within microns to avoid runout and parasitic radial loads that raise vibration and heat.

2. Controller Compatibility

Match drive current rating, commutation type (FOC/field-oriented), feedback interface (ABZ, BiSS-C, SSI, TTL/HTL), and safety I/O. Confirm loop bandwidth targets (position/velocity/current) and available notch/anti-resonance filters.

3. Power Supply Configuration

Size DC bus voltage to meet top speed with Ke margin; size continuous/peak current for RMS and transient demands. Include braking resistor or regenerative handling for fast decel cycles.

4. Use Mosrac Application Engineering Support

Share your motion profile, load inertia, duty cycle, ambient/thermal constraints, and feedback/drive preferences. Mosrac’s engineers will recommend the optimal Housed Direct Drive Torque Motor, encoder option, and drive settings, plus provide mounting and tuning guidance for rapid commissioning.

Recommended Reading: Custom Motor – Importance, Key Considerations, Applications, Differences between Standard and Custom Motor

Common Challenges and Solutions

✅ Heat Dissipation

DD Motors generate significant heat during continuous torque delivery. Efficient cooling is vital to prevent performance loss or magnet demagnetization. Mosrac’s housed DD motor design integrates advanced stator cooling channels and thermally optimized housings that improve heat dissipation, ensuring stable operation, extended life, and consistent torque output under demanding loads.

✅ Control Tuning

Achieving smooth and responsive motion requires precise servo tuning. Engineers must fine-tune control loops to balance stiffness, responsiveness, and damping. Using advanced PID and field-oriented control (FOC) techniques minimizes torque ripple and vibration. Mosrac provides application-level support for tuning DD motor systems, enabling seamless integration into automation platforms.

✅ Cost Optimization

Although DD Motors has a higher upfront cost, its maintenance-free design and long operational life drastically reduce downtime and replacement expenses. With no gear wear, lubrication, or part failures, total ownership costs decline over time. The resulting lifecycle savings far outweigh initial investments, ensuring superior ROI and long-term efficiency.

Future of Direct Drive Technology

✅ AI and Smart Motion Control

The next generation of Direct Drive (DD) technology is being shaped by AI and smart motion control systems. Artificial intelligence is now enabling predictive maintenance, where real-time sensor data is analyzed to forecast wear patterns and optimize performance before faults occur. This reduces unexpected downtime and enhances system reliability in high-throughput environments such as robotics, semiconductor fabrication, and precision assembly lines.

Direct Drive Technology in AI & Smart Motion Control Systems

The integration of digital twins, virtual replicas of physical motors, allows engineers to simulate behavior, stress, and thermal responses before deployment. Combined with IoT-based condition monitoring, manufacturers can continuously track parameters like temperature, vibration, and torque, achieving self-optimizing motion systems.

The ongoing R&D at Mosrac focuses on developing sensor-integrated DD motor systems capable of smart data exchange between motor controllers, encoders, and predictive algorithms. These next-generation solutions are designed to provide adaptive tuning, efficiency optimization, and real-time diagnostics, aligning with Industry 4.0 and AI-era automation demands.

✅ Integration with Robotics & Semiconductor Automation

As robotics and semiconductor systems demand more compact and efficient motion solutions, miniaturization is emerging as a key trend. Frameless DD motor designs offer the perfect balance of torque density and design flexibility, allowing OEMs to embed motors directly into robotic joints or wafer-handling mechanisms.

These frameless configurations eliminate unnecessary housing mass while maintaining precision torque control, ideal for compact automation systems.

How Mosrac Redefines DD Motor Excellence?

✅ Our Product Innovation

At Mosrac, innovation lies at the heart of every Direct Drive (DD) motor we engineer. Our Housed DD Motors are designed for plug-and-play integration, offering a fully enclosed structure with optimized cooling, precise alignment, and minimal maintenance requirements — perfect for demanding industrial and robotic applications.

For OEMs seeking greater design flexibility, our Frameless DD Motors provide compact, lightweight configurations that can be seamlessly embedded within robotic joints, semiconductor positioning systems, or custom automation assemblies. These motors offer high torque output in a smaller footprint, maximizing both performance and design freedom.

In addition, Mosrac specializes in custom torque motor solutions tailored to specific operational needs — from high-torque, low-speed rotary platforms to ultra-smooth, low-cogging applications in precision motion control. Every unit is built to deliver long-term reliability and consistent torque density under extreme conditions.

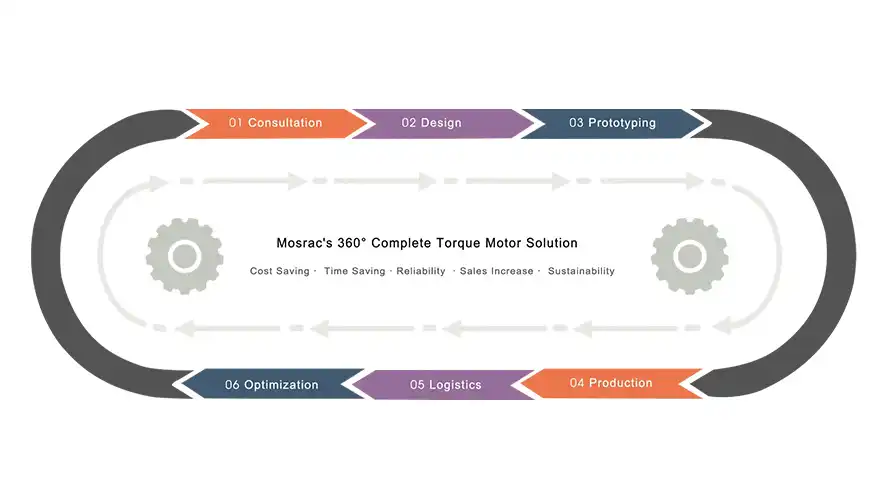

✅ Why Choose Mosrac?

Beyond aesthetics, every business has unique torque motor needs. Our modular approach and expert team ensure tailored solutions that optimize costs, enhance sustainability, and meet your specific goals whether it's a frameless or housed DDR motor.

◉ Precision Engineering Heritage: Decades of expertise in torque motor and encoder design ensure consistent performance and reliability.

◉ Custom Winding and Encoder Options: Each DD motor can be optimized for torque, speed, and positional accuracy to suit your unique system requirements.

◉ Global Supply Reliability: Mosrac maintains strong supply chain networks to guarantee on-time delivery and continuous support worldwide.

◉ Technical Consultation and Integration Support: Our engineering team assists with sizing, control integration, and performance tuning to ensure flawless deployment.

Contact the engineering team at Mosrac today to discuss your precision motion requirements, and discover how our DD motor technology can elevate your next project.

Conclusion

Direct Drive Motors (DD Motors) have become the backbone of modern precision systems, driving innovation in robotics, semiconductor manufacturing, medical equipment, and industrial automation. Their zero-backlash architecture, high torque density, and maintenance-free performance enable unmatched accuracy, speed, and reliability — essential for today’s high-demand motion control applications.

By eliminating mechanical transmissions, DD motors redefine efficiency and precision at every level of engineering design. Mosrac stands at the forefront of this evolution, delivering high-performance housed and frameless DD torque motors that combine cutting-edge technology with robust reliability.

Explore our DD Motor Series to find the ideal fit for your automation or robotics system, or contact us for any further information!

Looking for a Custom Solution?

Tell Us about your requirements, and our application engineers will help you find the right solution today!

Frequently Asked Questions (FAQs)

Q. What is a DD Motor and how does it work?

A. DD Motor, or Direct Drive Motor, delivers torque directly to the load without gears, achieving smoother, quieter, and more precise motion control.

Q. What are the main advantages of DD Motors?

A. They offer zero backlash, high torque density, improved accuracy, and maintenance-free operation — ideal for robotics, CNC, and semiconductor automation.

Q. How are DD Motors different from servo motors?

A. Unlike servo motors with gearboxes, DD motors connect directly to the load, removing mechanical play and reducing noise.

Q. What industries use Direct Drive Motors?

A. DD motors are widely used in industrial automation, robotics, medical imaging, metrology, and aerospace systems requiring precision motion.

Q. Why choose Mosrac DD Motors?

A. Mosrac offers high-performance housed DD torque motors engineered for precision, efficiency, and reliability in demanding industrial environments.