Discover the key differences between slotted and slotless motors, including their design principles, performance impacts, and applications.

Slotted vs Slotless Motors

Introduction

In the world of precision motion control, every design choice and micron of movement matters. Yet many engineers face the challenge of choosing the right motor architecture — slotted or slotless — to achieve peak performance. The wrong choice can lead to unwanted vibration, cogging torque, or inconsistent motion, compromising the efficiency of advanced automation and robotics systems.

That’s where understanding the core design difference becomes crucial. The direct drive (DD) motors and torque motors redefine mechanical precision by eliminating gears, ensuring smoother torque delivery and higher dynamic response.

We at Mosrac, specialize in engineering high-performance direct-drive and brushless frameless torque motors optimized for both slotted and slotless configurations, helping automation, robotics, and industrial innovators achieve speed, accuracy, and reliability.

What Are Slotted Motors?

Construction and Working Principle

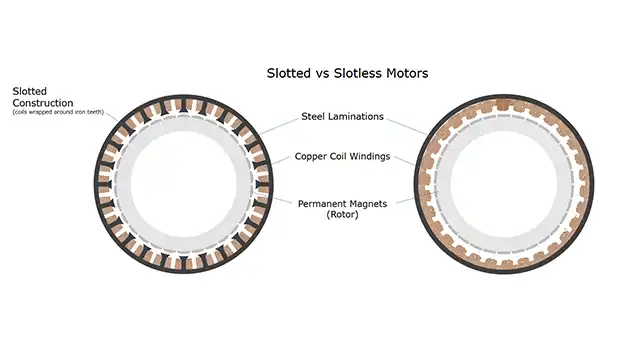

The slotted motor is built around a stator that contains slots, precisely machined grooves in its laminated steel core. Inside these slots, copper windings are carefully embedded to form electromagnetic poles when energized. The rotor, typically containing permanent magnets rotates within the stator’s magnetic field.

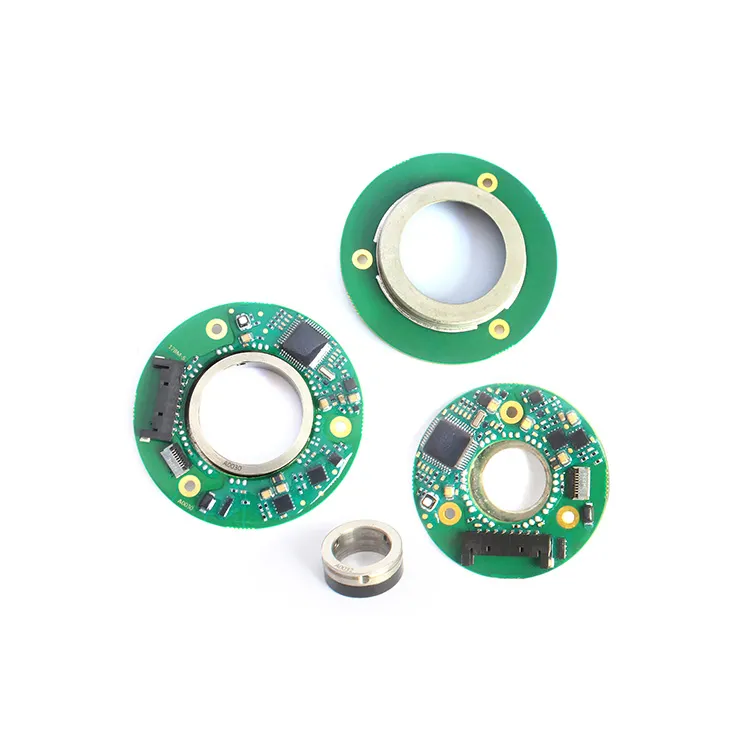

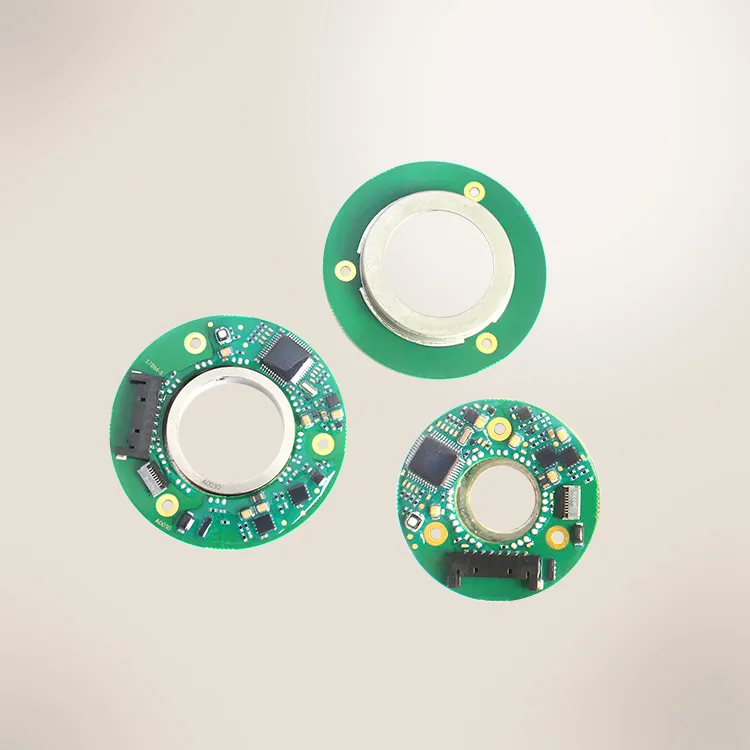

Slotted Motor

Slotted motors with various stator OD size

When current passes through the windings, the stator generates a magnetic flux that interacts with the rotor magnets, producing torque. The presence of slot teeth — thin steel segments between the slots — helps focus the magnetic flux, increasing flux density and torque output. However, the discrete slot structure also causes cogging torque, a periodic resistance as magnets align with slot openings.

To minimize losses, manufacturers use high-quality stator laminations, which reduce eddy currents and improve energy efficiency, making slotted designs ideal for high-torque, industrial-grade applications.

Advantages of Slotted Motor Design

1. Higher Torque Density

The slotted configuration concentrates magnetic flux around the rotor, delivering greater torque per unit volume compared to slotless designs. This makes it suitable for heavy-duty applications, such as industrial automation, conveyors, and robotics joints.

2. Better Thermal Dissipation

With windings embedded directly into the stator iron, heat conduction is more efficient. The metal core acts as a thermal sink, allowing for better cooling and higher continuous current handling.

3. Cost Efficiency for High-Load Applications

Slotted motors are easier to mass-produce and require simpler winding systems, offering cost-effective performance for operations demanding strong mechanical force and long duty cycles.

Limitations of Slotted Motors

1. Increased Cogging Torque

The interaction between rotor magnets and stator slots produces detent forces known as cogging torque, which can cause jerky motion at low speeds—undesirable for precision control systems.

2. Higher Noise and Vibration Levels

The periodic flux variations as magnets pass over slot openings induce magnetic noise and vibration, affecting smoothness and acoustic performance in sensitive environments.

3. More Complex Assembly Process

Embedding windings into narrow slots and ensuring uniform insulation requires precise manufacturing and quality control, which increases assembly complexity and the potential for mechanical stress over time.

In summary, slotted motors offer high torque density and efficient thermal performance, making them the go-to solution for robust industrial operations. However, their inherent cogging torque and vibration characteristics require careful design optimization.

Recommended Reading: Motor Cogging: Causes, Effects, and Proven Solutions for Smoother Performance

What Are Slotless Motors?

Construction and Working Principle

The slotless motor eliminates the traditional stator slot-and-tooth design found in slotted motors. Instead, it uses a smooth stator bore wrapped with air-gap windings or encapsulated coils. These coils are fixed directly within the air gap using epoxy or composite supports, forming a coreless configuration that eliminates slot-induced magnetic irregularities.

Slotless Motors

When current flows through these coils, they generate a uniform magnetic field that interacts with the rotor’s permanent magnets. Because slot teeth don’t distort the field, air-gap flux remains smooth and symmetrical, producing consistent torque without cogging.

This design also enhances back electromotive force (back-EMF) linearity, improving control precision. Furthermore, the absence of ferromagnetic teeth minimizes eddy currents, reducing energy losses and enabling extremely smooth motion. This is a hallmark of slotless technology in precision robotics and medical devices.

Advantages of Slotless Motors

1. Zero Cogging Torque — Perfect for Smooth Motion Control

The absence of stator slots eliminates cogging effects, allowing for frictionless, vibration-free rotation, which is crucial for applications such as surgical robotics, optical scanners, and gimbals.

2. Reduced Electromagnetic Noise

With no slot-induced flux variations, slotless motors generate minimal electromagnetic interference (EMI) and operate quietly, making them suitable for noise-sensitive environments.

3. High Acceleration Response

The lightweight air-gap windings have low inductance and inertia, enabling fast current response and rapid acceleration. This is essential for high-speed, dynamic control systems such as pick-and-place machines or servo axes.

Limitations of Slotless Motors

1. Lower Torque Density

The lack of slot teeth reduces magnetic flux concentration, resulting in lower torque output compared to slotted motors of the same size—a trade-off for smoother operation.

2. Requires Advanced Control Electronics

To maintain precise torque and position control, slotless designs depend on sophisticated servo drives and feedback systems, increasing system complexity.

3. Higher Manufacturing Cost

Producing uniform air-gap windings or encapsulated coils demands precision engineering, advanced insulation, and thermal management — making slotless motors more expensive to manufacture.

In essence, slotless motors deliver exceptional smoothness, low noise, and ultra-fast response, excelling in applications where motion precision outweighs raw torque output.

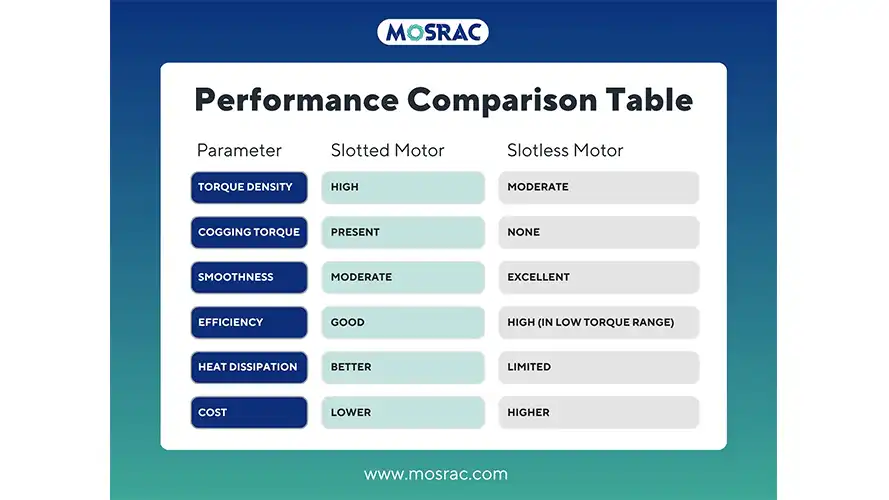

Slotted vs Slotless Motors — Key Design Differences

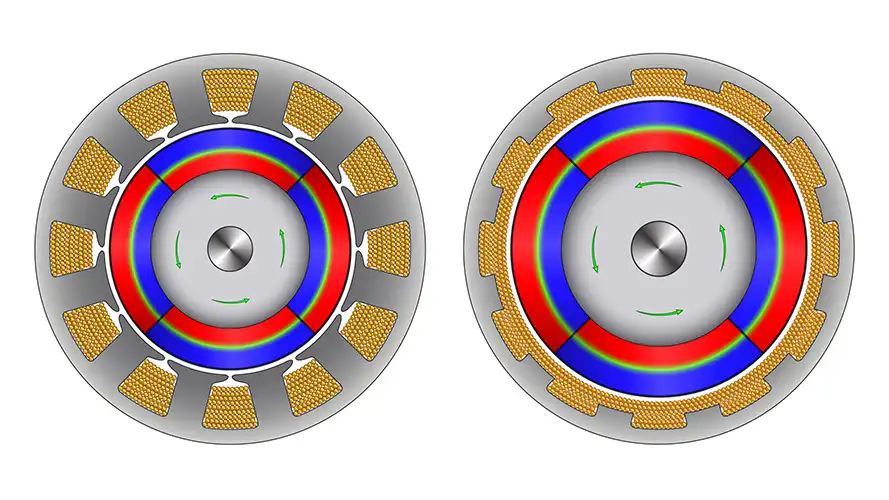

1️⃣ Magnetic Circuit Design

The primary distinction between slotted and slotless motors lies in how each manages its magnetic flux path.

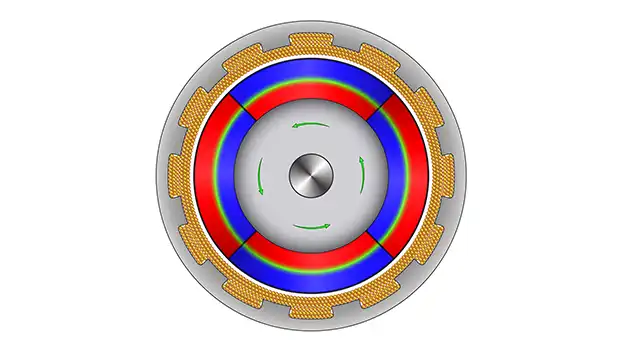

Slotted vs Slotless Motors; Source: kollmorgen

In slotted motors, the magnetic flux travels through stator teeth and slot walls before linking with the rotor magnets. This focused flux path increases magnetic flux density, generating a strong torque output. However, because the rotor magnets constantly align with the slot openings, this design introduces cogging torque — a periodic resistance that disrupts smooth rotation.

In contrast, slotless motors feature a smooth stator bore without teeth, allowing the magnetic field to distribute uniformly around the air gap. This eliminates cogging torque, creating a consistent electromagnetic interaction. As shown in comparative flux analysis graphs (often used in motor simulation tools like ANSYS Maxwell), slotless configurations exhibit smoother flux lines and zero cogging torque zones, leading to more stable performance in precision applications.

2️⃣ Torque & Speed Characteristics

The geometry of the stator slots significantly influences the torque ripple and overall speed performance of slotted motors. Narrow slots with small teeth yield higher torque density but greater torque ripple, while wider slots reduce ripple but lower torque. This makes slot design a delicate engineering trade-off between torque smoothness and density.

On the other hand, slotless motors produce a near-linear torque-speed curve, meaning torque output remains steady across a wide speed range. With no slot-induced variations, the back-EMF waveform is almost perfectly sinusoidal, enabling precise torque control and consistent acceleration. This characteristic is vital in applications like robotic arms, servo drives, and semiconductor handling systems, where even slight motion variations can affect accuracy and repeatability.

3️⃣ Efficiency and Thermal Management

Slotted motors benefit from superior thermal conductivity because their embedded copper windings are in direct contact with the iron core, allowing heat to dissipate efficiently. However, this configuration also increases core losses, particularly eddy current and hysteresis losses, since magnetic flux is concentrated within the laminated steel.

In slotless motors, the absence of teeth reduces magnetic core losses, improving overall energy efficiency, especially in low-torque, high-speed conditions. Yet, because windings are surrounded by air or resin rather than iron, thermal dissipation can be challenging.

To address this, Housed Direct Drive Torque Motors are engineered with enhanced thermal paths and high-conductivity stator designs, ensuring effective heat management even under heavy load or continuous operation.

4️⃣ Manufacturing and Cost Considerations

From a production standpoint, slotted motors are simpler and more cost-effective to manufacture. The use of conventional stator laminations and slot winding processes allows for high-volume production at lower cost, making them ideal for industrial and automotive markets where performance-to-cost ratio is critical.

Conversely, slotless motors require advanced winding techniques, such as air-gap or encapsulated coil construction, demanding precise mechanical alignment and insulation. This precision engineering increases manufacturing time and cost but delivers exceptional performance consistency. Hence, slotless motors are typically chosen for premium, high-precision applications in robotics, aerospace, and medical technology — where smooth motion and accuracy outweigh cost considerations.

Applications and Use Cases

↪️ Where Slotted Motors Excel?

Slotted motors are the powerhouse choice for demanding applications that require high torque output, mechanical robustness, and cost efficiency.

In industrial automation, they drive heavy-duty machinery such as CNC equipment, presses, and packaging systems, where torque density and endurance take priority. Their sturdy stator-slot architecture allows for long operational lifespans under continuous loads.

In high-torque robotics, slotted motors power robotic joints, actuators, and automated guided vehicles (AGVs), delivering precise yet forceful motion control. Similarly, in conveyor drives and power tools, their superior thermal handling ensures stable performance under prolonged use, making them ideal for rugged industrial environments that demand reliability and efficiency.

↪️ Where Slotless Motors Lead?

Slotless motors, by contrast, dominate fields where smooth motion, minimal vibration, and high responsiveness are essential.

In medical imaging systems such as MRI scanners or robotic surgery platforms, their zero-cogging performance enables vibration-free operation and quiet precision, ensuring patient safety and diagnostic accuracy.

In semiconductor wafer handling, slotless designs prevent micro-vibrations that can disturb positioning, enabling sub-micron accuracy crucial for cleanroom robotics and photolithography tools. Similarly, in aerospace actuators and optical positioning systems, their coreless stator design guarantees ultra-smooth, low-noise rotation for instruments that rely on stability and repeatability under extreme conditions.

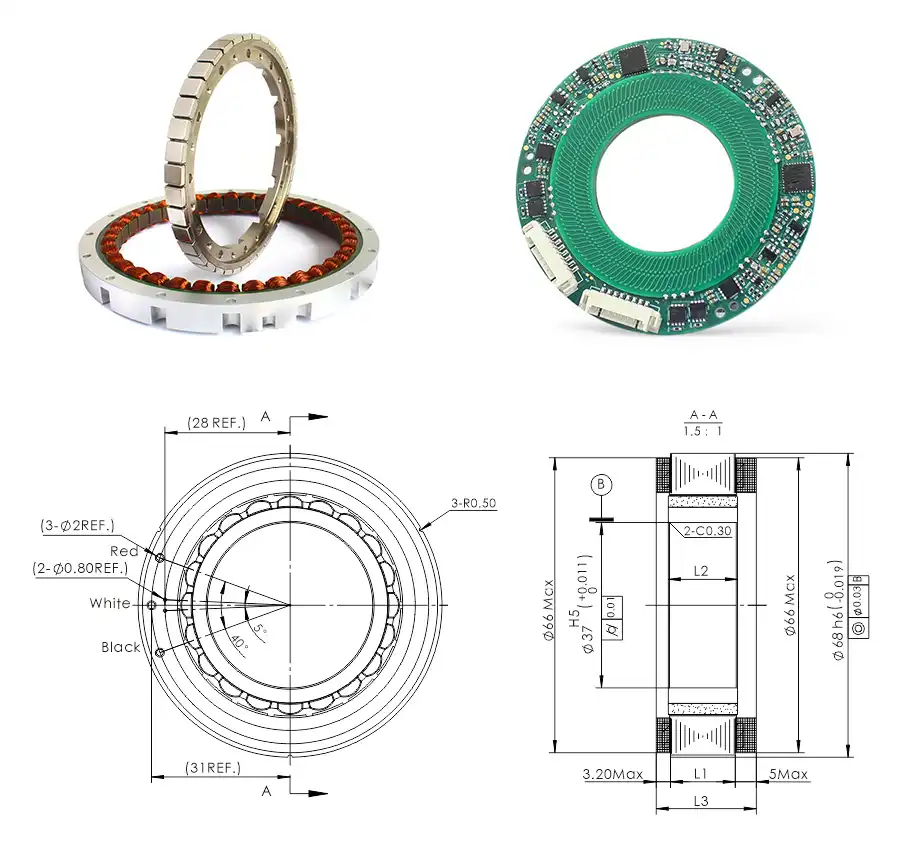

Brushless DC Frameless Torque Motors

These Frameless Torque Motors by Mosrac are engineered for high-precision, slotless-like performance, combining compact design with high torque density.

Engineering Considerations for Selection

Choosing slotted vs slotless motors is not simply a matter of cost. It’s an engineering decision that directly influences performance, precision, and reliability. Below are the key factors every design engineer should evaluate before making the choice:

Factors to Evaluate

1. Required Torque vs. Motion Smoothness

If the application demands high torque density—for example, in industrial automation, robotics arms, or heavy-duty servo drives—slotted motors are often the right fit. However, if smooth, cogging-free motion is more critical, such as in optical instruments or medical robots, slotless motors outperform due to their consistent torque and vibration-free behavior.

2. Available Space and Thermal Limits

Slotted designs can handle higher continuous current and dissipate heat efficiently through the iron core, ideal for compact but thermally demanding systems. In contrast, slotless motors may require additional cooling or derating in high-load environments, making them better suited to low-torque, high-speed applications.

3. Control Electronics Compatibility

Slotless motors typically require advanced servo drives and high-resolution feedback encoders to maintain torque linearity and positional accuracy. Slotted motors, being more magnetically predictable, can operate with simpler control systems, lowering overall system complexity.

4. Lifetime and Maintenance Preferences

With fewer mechanical stresses on bearings and reduced magnetic pull variation, slotless motors often deliver longer operational lifespans in precision environments. Slotted motors, though robust, may experience wear-related effects from torque ripple and vibration over time in high-speed applications.

Decision Framework

Choosing between the two motor architectures depends on the engineering priorities of your system design. Below is a simplified flow-style decision guide that can help:

Step 1: Determine Performance Priority

If Torque Density > Smoothness, choose Slotted Motor

If Smoothness > Torque Density, choose Slotless Motor

Step 2: Evaluate Thermal and Space Constraints

For limited cooling space but a higher load, select Slotted Motor

For low heat load and sensitive motion, select Slotless Motor

Step 3: Review System Complexity

Basic control system → Slotted Motor

Advanced servo control → Slotless Motor

Step 4: Consider Cost and Application Lifecycle

Budget-driven, industrial applications → Slotted Motor

Precision-driven, long-lifecycle systems → Slotless Motor

In summary, slotted motors are ideal for torque-intensive, cost-sensitive environments, while slotless motors dominate in high-precision, low-noise systems.

Mosrac’s Precision Motor Solutions

How Mosrac Optimizes Both Designs?

Motor innovation goes beyond standard engineering at Mosrac! It’s about achieving the perfect synergy between torque density, smooth motion, and thermal performance. Our R&D team continuously refines both slotted and slotless motor architectures to deliver unmatched precision for diverse industrial applications.

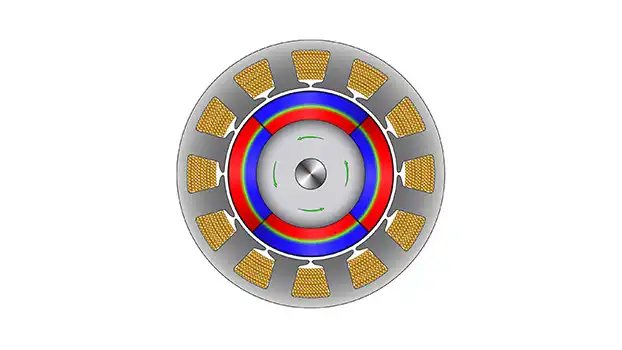

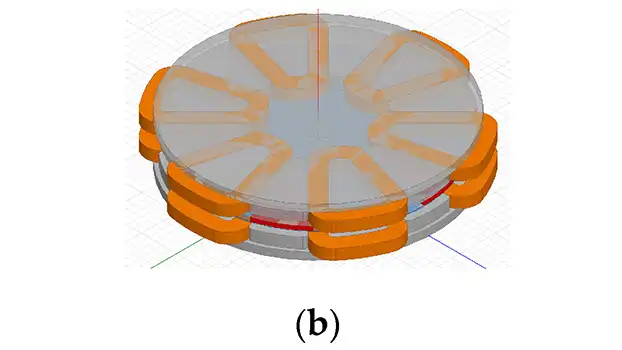

Through custom coil design, we optimize copper distribution and magnetic efficiency, ensuring balanced flux density and minimal eddy losses. Proprietary winding geometry and advanced high-efficiency lamination stacks reduce hysteresis and core losses, improving overall power efficiency. In slotted designs, our engineers employ cogging torque reduction techniques such as skewed stators and optimized magnet segmentation, ensuring smoother torque output even under load variations.

Cogging Torque Reduction Techniques in Axial Flux Permanent Magnet Machines; Source: MDPI

To further enhance precision and feedback accuracy, Mosrac integrates high-resolution magnetic encoders directly within motor assemblies. This fusion of motor and sensor technology enables real-time position control, ideal for robotics, defense automation, and semiconductor systems.

Industry Use Cases

Our hybrid motor architecture empowers a wide range of industries that demand both precision and reliability:

Robotics: Slotless-inspired Mosrac torque motors deliver fluid motion and fast dynamic response, critical for collaborative and surgical robots.

Automation: High-torque slotted motors ensure durability in assembly lines, packaging systems, and material handling robotics.

Defense Systems: The compact direct drive motors by Mosrac withstand vibration, heat, and high-load conditions, supporting turret positioning and drone stabilization.

Medical Devices: The slotless motor architecture ensures vibration-free torque control in robotic surgical arms and diagnostic instruments requiring absolute precision.

By merging advanced design engineering with precision feedback technologies, our motors bridge the gap between torque power and motion perfection, ensuring clients achieve maximum control, efficiency, and operational lifespan in every application.

Emerging Trends and AI-Era Optimization

Digital Twin & Simulation in Motor Design

The rise of artificial intelligence (AI) and digital twin technology has revolutionized how engineers design and optimize both slotted and slotless motors. Digital twin — a virtual replica of the physical motor — allows engineers to simulate magnetic field interactions, thermal behavior, and mechanical stress under real-world operating conditions.

Digital Twin: Boosting Efficiency and Driving Innovation

Through AI-based optimization algorithms, magnetic flux distribution, winding geometry, and lamination thickness can be precisely tuned to reduce core losses and improve power density before physical prototyping. Predictive analytics then analyzes real-time data from sensors and prototypes, enabling engineers to anticipate performance deviations, torque ripple, or heat buildup — all before production begins.

This AI-assisted simulation environment shortens development cycles, reduces testing costs, and enhances overall motor efficiency and reliability, setting a new benchmark in motion control innovation.

Smart Manufacturing and Quality Control

In the AI-driven manufacturing era, motor production is evolving from reactive inspection to predictive quality control. Advanced machine vision systems and AI algorithms now evaluate stator alignment, coil winding precision, and magnet placement during manufacturing — ensuring each slotted or slotless motor meets exact electromagnetic tolerances.

For in-field operation, IoT-integrated performance monitoring continuously gathers motor health data, including vibration, current flow, and temperature fluctuations. AI models then analyze this data to predict maintenance intervals, detect anomalies, and enhance long-term durability.

This convergence of AI, IoT, and smart analytics enables manufacturers like Mosrac to deliver motors that are not only engineered for precision but also intelligently optimized throughout their lifecycle — from digital design to real-world performance validation.

Conclusion

The comparison between slotted and slotless motors reveals that each design serves a distinct purpose in modern motion control systems. The slotted motors excel in delivering high torque density, efficient thermal dissipation, and cost-effective performance for heavy-duty industrial and automation applications. In contrast, slotless motors prioritize smooth, vibration-free motion, quiet operation, and high responsiveness, making them indispensable in precision-driven sectors such as medical robotics, optics, and aerospace.

Both architectures reflect unique trade-offs between power, precision, and efficiency. The right choice ultimately depends on the engineering goals, control system, and environmental constraints of your project.

We at Mosrac combine the best of both worlds through custom-engineered direct drive and frameless torque motors, ensuring optimized performance for every application.

Explore our advanced motor portfolio to find the ideal fit for your automation or robotics system, or contact us for any further information!

Looking for a Custom Solution?

Tell Us about your requirements, and our application engineers will help you find the right solution today!

Frequently Asked Questions (FAQs)

Q. What is the difference between slotted and slotless motors?

A. Slotted motors have stator slots holding windings, offering higher torque. Slotless motors use smooth stators, reducing cogging torque for precise, vibration-free motion — ideal for high-precision automation.

Q. Which is more efficient — slotted or slotless motor?

A. Slotless motors often deliver higher efficiency at lower torque due to minimal magnetic losses, while slotted motors perform better in high-load, torque-intensive applications.

Q. Why does cogging torque occur in slotted motors?

A. Cogging torque results from the interaction between rotor magnets and stator slots, creating a detent effect that causes torque ripple.

Q. What are slotless motors used for?

A. Slotless motors are used in robotics, optical systems, and medical devices requiring ultra-smooth, vibration-free operation with precise motion control.

Q. Does Mosrac manufacture slotless or slotted motors?

A. Mosrac designs both high-torque slotted and precision slotless architectures, available in frameless and housed direct drive torque motors.