In this article, you will get comprehensive knowledge on custom motors, including the importance, key considerations, and applications, while highlighting the unique advantages of choosing MOSRAC custom motors.

Introduction

Standard motors are widely used in various applications because of their generalized specifications. Selecting such a motor may seem convenient, but when applications require high performance, operation in complex environments, or specialized functionality—particularly in robotics, medical technology, and aerospace OEMs—only a custom-designed motor can provide the required precision and reliability.

A custom motor offers superior adaptability, maximum efficiency, and unique design features that are critical in robotics, medical technology, and aerospace systems.

Selecting the optimal custom motor is essential for project success. Key requirements include technical expertise, advanced customization capabilities, adherence to rigorous quality standards, comprehensive support services, and a demonstrated global presence.

To address these challenges, MOSRAC places innovation at the core of its strategy, offering a diverse portfolio of custom-built motors that position the company as a trusted partner for OEM clients worldwide.

This article reviews the differences between standard and custom motors, highlights the importance of customization, outlines key selection factors, and describes MOSRAC’s production process – emphasizing the unique advantages of selecting MOSRAC custom motors.

What is a Custom Motor?

A custom motor is an electric motor specifically designed, engineered, and manufactured to meet the requirements of a particular application. Unlike a “one-size-fits-all” solution, a custom motor is tailored to optimize performance, size, efficiency, and durability for the conditions in which it will operate.

Motor customizations can range from simple shaft modifications to complete motor redesigns. Custom motor engineering plays a critical role in robotics, medical, and aerospace OEM applications.

Standard Motors vs. Custom Motors

↪️ Equipment Performance:

Designed to fit a wide range of applications, standard motors may provide either insufficient or excessive power for a given task, leading to wasted energy. In contrast, custom motors deliver the precise load profile and maximize efficiency, enabling peak performance.

↪️ Costs:

Standard motors are inexpensive and readily available but may incur hidden costs due to inefficiencies and reduced performance. Custom motors require a higher initial investment but provide significant long-term savings through greater efficiency, enhanced reliability, and optimized performance.

↪️ Lead Time and Availability:

Standard motors prioritize immediate availability for a broad range of applications, whereas custom motors require a development phase, resulting in longer initial lead times but providing enhanced long-term availability and supply chain control.

Why Custom Motors Are Important

↪️ Boost Efficiency:

By precisely matching the motor’s power, torque, and thermal characteristics to the load, custom motors increase efficiency, minimize energy waste, reduce operating costs, and enhance overall system performance.

↪️ Elevate Performance:

Through extensive optimization of performance factors such as torque, speed, form factor, and motion control, custom motors enhance operation by meeting the precise specifications of a given application.

↪️ Guarantee Reliability:

Custom motors ensure reliability by addressing potential failure modes, including thermal overload, mechanical stress, and environmental challenges, resulting in a robust and dependable product.

↪️ Optimize Space:

To accommodate the physical constraints of a specific application, custom motors maximize available space, enabling smaller and lighter products while simplifying mechanical integration.

Key Considerations for Custom Motors

1️⃣ Optimize Form Factor for Maximum Versatility:

Optimizing the form factor of a custom motor is crucial for achieving superior product integration, expanding the application range, and enhancing overall system performance.

2️⃣ Unleash Torque Output for Peak Performance:

Maximizing torque output in a custom motor is crucial for achieving performance advantages, including superior acceleration, enhanced responsiveness, and the ability to handle heavy loads.

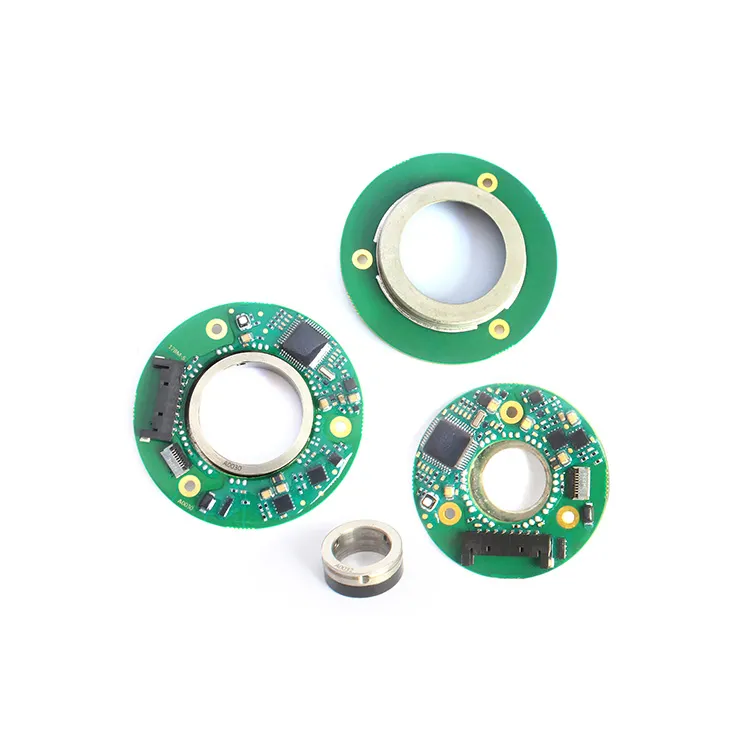

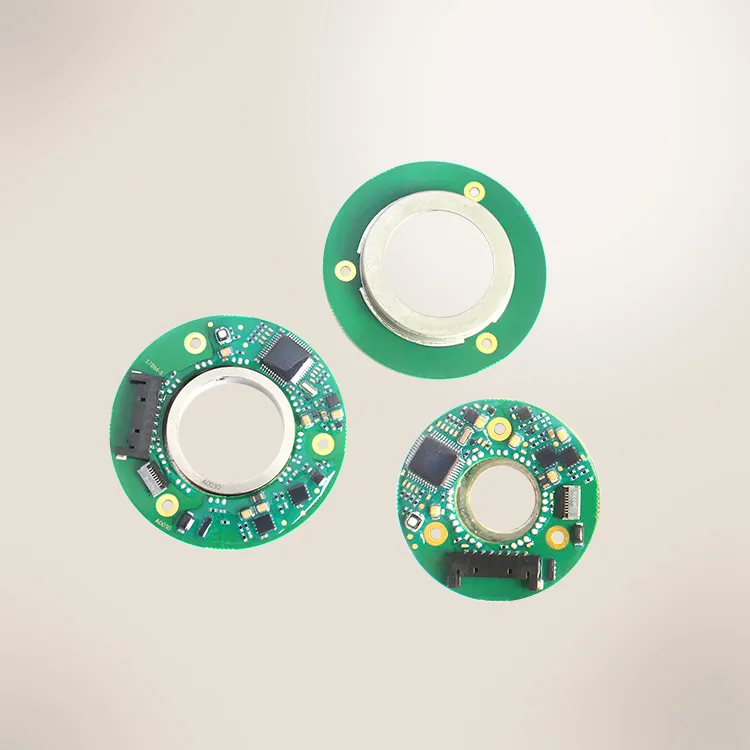

Fig.1: Customized motor with increased torque output

3️⃣ Engineer Winding Turns for Precision Control:

Configuring winding turns in a custom motor is essential for precision control, as they directly affect performance characteristics such as inductance, back electromotive force (EMF), and magnetic field quality. This precise engineering is vital for applications requiring high accuracy, smooth motion, and consistent performance in robotics and medical technology.

4️⃣ Minimize Cogging Torque for Smoother Motion:

Minimizing cogging torque in a custom motor is essential for achieving smooth, precise, and quiet motion, particularly in low-speed and positioning applications.

5️⃣ Harness Inductance to Elevate Efficiency:

Inductance is a fundamental electrical property influencing a custom motor's efficiency by affecting power loss, response time, and control system effectiveness. By engineering inductance carefully, energy losses can be minimized, heat managed, and performance optimized for a specific application.

6️⃣ Refine Pole and Stator Tooth for Magnetic Precision:

Improving the geometry of a motor’s poles and stator teeth is essential for magnetic accuracy. By carefully shaping these components, a custom motor can generate a more uniform and predictable magnetic field in the air gap, enhancing torque, efficiency, and motion control.

Fig.2: Customized motor with refined pole and stator teeth

7️⃣ Control Thermal Resistance and Time Constant to Maximize Reliability

Controlling thermal resistance and time constant is essential for maximizing a custom motor’s reliability and lifespan. These two thermal properties determine how effectively the motor manages and responds to internal heat – the primary cause of insulation degradation, demagnetization, and mechanical wear.

8️⃣ Select Motor Type to Drive Performance:

Selecting the appropriate motor type is the most fundamental design decision for a custom motor, as it defines performance characteristics, applications, and trade-offs. Aligning the motor's core operating principles with the application's specific demands ensures that the final product is not only efficient but also precisely tailored to its task.

9️⃣ Leverage Advanced Materials to Strengthen Durability

Leveraging advanced materials is critical for enhancing durability in a custom motor. Such materials improve thermal management, increase structural integrity, and provide superior resistance to environmental degradation, thereby extending operational lifespan.

Fig.3: Motor design schematic displayed on computer

Applications of Custom Motors

1. Robotics:

In robotics, custom motors play a critical role by improving performance, precision, and integration. Customized winding and magnet placement techniques minimize cogging torque, enabling the smooth, precise motion required for delicate tasks like robotic assembly, surgery, or welding.

2. Medical devices:

Custom motors are essential in the medical device industry for applications requiring high precision, reliability, miniaturization, and seamless integration. Custom designs enable manufacturers to meet stringent medical-grade standards and develop devices that are safe, efficient, and tailored to specific therapeutic or diagnostic tasks.

3. Aerospace:

Custom motors are vital in the aerospace industry for applications demanding extreme precision, reliability, high power-to-weight ratio, and durability in harsh environments. Customization enables engineers to meet the stringent safety and performance standards required for commercial and military aircraft as well as spacecraft.

4. Automotive

Custom motors play a vital role in powering electric and hybrid vehicles by delivering the precise torque, speed, and power density required for high-performance propulsion. In autonomous vehicles, advanced custom motors work in conjunction with sensors and AI systems to control steering, braking, and acceleration, thereby enabling self-driving functionality.

5. Manufacturing

Custom motors used in manufacturing enhance operational efficiency and integrate seamlessly into automated systems by satisfying specific requirements for speed, torque, size, and operating environment. Key applications include powering robotic systems for precise motion control, driving material-handling equipment such as conveyors and packaging machines, and operating CNC machinery for customized manufacturing processes.

Fig.4: Custom motor assembly on industrial equipment

6. Science and Astronomy

Custom motors are used for high-precision motion control in scientific instruments and electromechanical systems. Specialized applications include driving gimbals and optoelectronic systems, adjusting wind turbine blades, positioning measurement heads in metrology equipment, and controlling telescopes and other astronomical instruments with exceptional accuracy and stability.

What are the Essential Steps of MOSRAC Motor Customization?

1. Requirements Analysis and Application Assessment:

✔Define Performance Specifications: The customer provides specific parameters, which may include the required torque, power, speed, voltage, and efficiency.

✔Assess Application Constraints: MOSRAC experts evaluate the operating conditions, including the required form factor, available space, environmental factors (e.g., dust), and mounting requirements.

✔Identify Suitable Motor Architecture: Based on the requirements, MOSRAC determines the most appropriate motor architecture, such as a frameless or housed direct-drive motor.

2. Design and Engineering:

✔Custom Windings: Adjusting the winding configuration ensures that the motor delivers the required maximum torque at the desired speed.

✔Custom Shafts and Accessories: Shaft options are selected or designed to meet the specific mechanical integration requirements of the applications.

✔Create the Solution Proposal: MOSRAC provides the customer with a detailed specification sheet and a price quotation for approval.

3. Production and Manufacturing:

✔Source Materials: All necessary components, such as custom-wound stators and rotors, are prepared for assembly.

✔Manufacturing: The motor is built according to customized specifications, produced using flexible manufacturing capabilities.

4. Quality Assurance and Testing:

✔Performance Verification: The motor is tested against the agreed-upon performance metrics, such as torque, speed, and efficiency.

✔Reliability Testing: The motor’s durability and long-term reliability are verified to ensure it can withstand the operating environment of the applications.

5. Delivery and After-Sales Support:

✔Delivery: The custom motor is packaged and delivered to the customer for integration into the customer’s equipment.

✔Customer Service: The process is supported by MOSRAC's dedicated customer service team, which remains committed to the customer relationship beyond the initial sale.

What Are the Advantages of MOSRAC Custom Motor Solutions?

A: High Torque Density and Precision:

A customized motor minimizes the overall size and weight of the assembly, producing a high power-to-weight ratio that is a key indicator of torque density. This design enables a direct and rigid connection between the motor and the load, ensuring highly accurate positioning.

B: Compact and Lightweight:

By eliminating the motor's outer housing, a customized motor configuration results in a significantly more compact and lightweight solution. This configuration also reduces system complexity, operational noise, and vibration.

C: Reduced Complexity and Maintenance:

MOSRAC's direct-drive motors power the workstation plate or machinery, removing the need for belts, chains, and gearboxes. This eliminates the complexity and potential failure points associated with these components.

D: Easy Integration:

By eliminating the need for traditional transmissions such as gears or belts, MOSRAC motors provide a highly reliable, precise, and compact solution for demanding applications, including robotics, medical machinery, and automation.

E: Direct Drive Benefits:

MOSRAC's direct-drive torque motors feature a high power-to-weight ratio, delivering exceptional power in a compact and lightweight design. MOSRAC offers customized direct drive motor solutions tailored for precise applications.

F: Improved Efficiency:

The most significant efficiency improvements in custom motors come from specialized winding designs. MOSRAC can design custom windings to ensure maximum torque and efficiency at a specific, desired speed. Optimizing windings reduces electrical losses, thereby directly increasing overall motor efficiency.

G: Space Optimization:

The ability to customize a motor's height, outer diameter (OD), and inner diameter (ID) to the specific dimensions of an application allows for more compact integration.

H: Reduced Costs:

By eliminating components such as belts and chains, direct-drive custom motors require less ongoing maintenance, thereby lowering overall operating costs.

Three Examples of Successful MOSRAC Custom Motors

Conclusion:

Standard motors are reliable in many industrial settings but exhibit notable limitations, such as lower efficiency, fixed speed, low starting torque, maintenance issues, and a shorter lifespan. In contrast, customized motor solutions are more technically advanced and cost-effective. Customized motors can meet specific requirements and offer a wide range of advantages, including meeting force requirements, accommodating unique form factors, providing torque output, ensuring precise control parameters, and supporting different order quantities.

MOSRAC motors can be customized by tailoring their designs to specific application needs, offering options for different torque, speed, and efficiency profiles through custom windings and shaft configurations. Customers can also select or request custom features to meet precise performance requirements for applications in fields such as robotics, medical devices, and aerospace OEMs.

Contact us at sales12@mosrac.com with your application requirements, sales inquiries, technical support requests, or to place a sample order. We will apply our experience, engineering talent, and manufacturing resources to provide the best value-added solution for your needs.