1. Introduction

Choosing the right motor for your design isn’t easy! Engineers often face a trade-off: standard servo motors offer precision and reliability, but they can add bulk and limit flexibility. On the other hand, frameless motors provide compactness and torque density, yet require more integration effort.

Get this choice wrong, and the impact can be costly. You might end up with wasted space, overheating issues, unnecessary maintenance, or even complete redesigns. In competitive industries like robotics, medical devices, or semiconductor equipment, these delays can mean lost revenue and missed opportunities.

Since 2010, Mosrac has been a global leader in direct-drive torque motor technology, offering both frameless and housed servo solutions. In this guide, we’ll compare their performance, integration, and applications, helping you make a confident choice for the best motor for your project.

2. Understanding the Basics

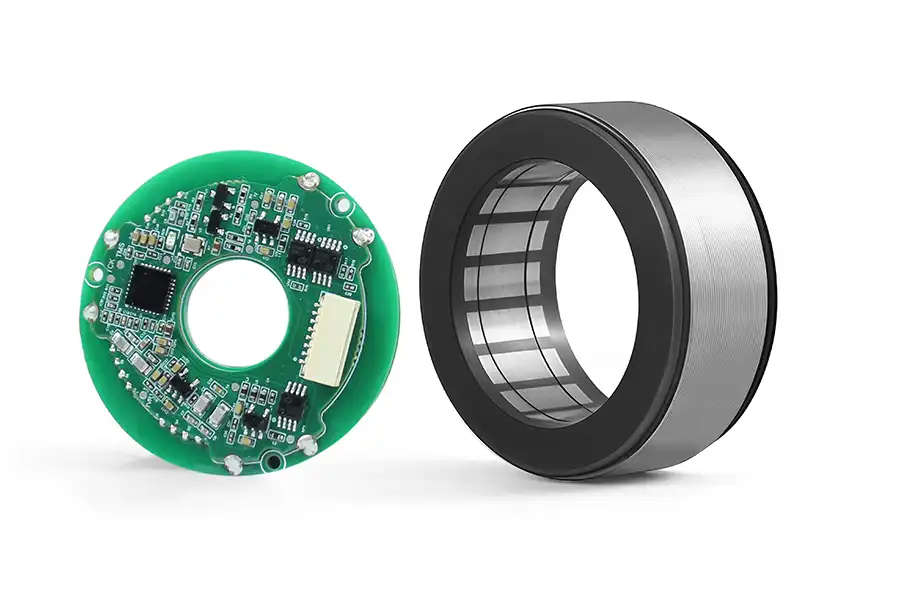

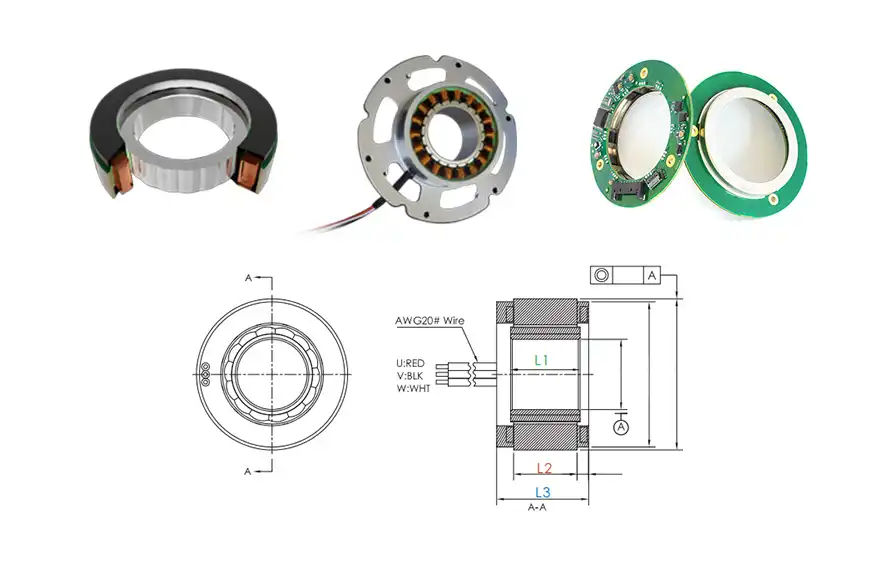

↪️: What Is a Frameless Motor?

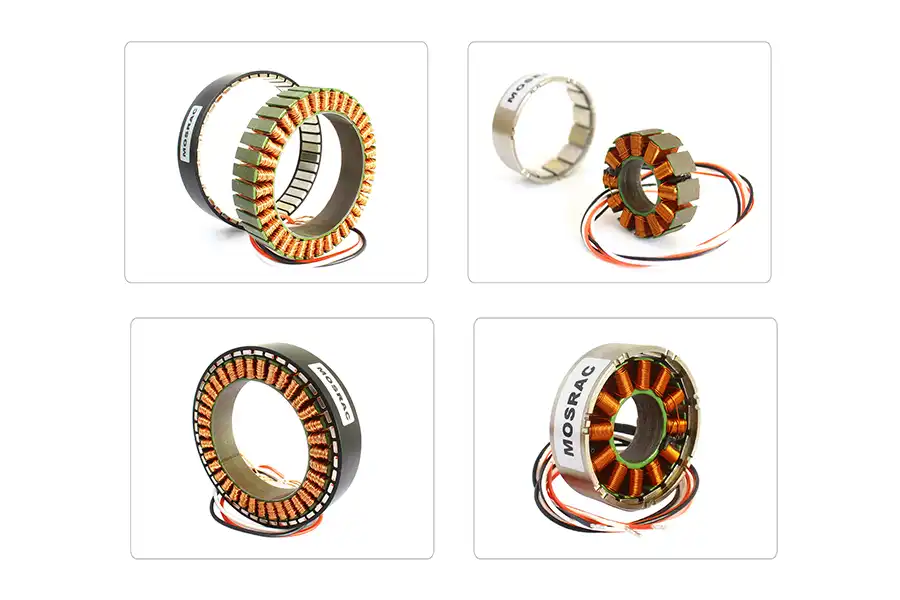

A frameless motor consists of two components: the stator (containing the coil windings) and the rotor (with permanent magnets). Unlike a standard servo motor, a frameless motor has no built-in housing, bearings, or feedback device. Sometimes called a “frameless servo,” it is designed to be integrated directly into the machine structure, offering ultimate design flexibility.

Potting Frameless Direct Drive Torque Motors

Open-winding (Un-potted) Frameless Brushless DC Torque Motors

The benefits of frameless motors include:

◉ Compact Size: No bulky housing means more freedom in tight spaces.

◉ High Torque Density: Frameless designs deliver impressive torque output relative to their weight.

◉ Custom Integration: Engineers can decide how the motor is cooled, protected, and supported.

The U-Series Frameless Motors highlight these advantages. Available in both inrunner and outrunner configurations, they provide slim, high-torque kits such as:

◉ U25 Kit (25 mm OD) delivers only a few hundredths of a newton-meter but is ultracompact for tight spaces

◉ U38 Kit (38 mm OD) offers a balanced mid-range option, combining compact size with reliable torque output.

◉ U115 Kit (115 mm OD) can provide tens of newton-meters of torque for more demanding loads

Mosrac even offers frameless outrunner designs and various stack lengths within each diameter to fine-tune the torque and speed characteristics. Because there’s no built-in encoder by default, you can choose any matching magnetic encoder or another feedback device as needed.

Frameless Outrunner Torque Motors

These frameless motors give you maximum design freedom – you essentially build the motor into your machine as if it were a custom part of the structure. This can lead to improved thermal dissipation (your machine housing can act as a heat sink), reduced weight, and the ability to achieve precisely the form factor your application requires.

In short, servo motors offer a plug-and-play solution with built-in feedback and protection. The frameless motors, on the other hand, give maximum flexibility and compactness, making them ideal for high-tech industries like robotics, medical devices, and aerospace.

↪️: What Is a Servo Motor?

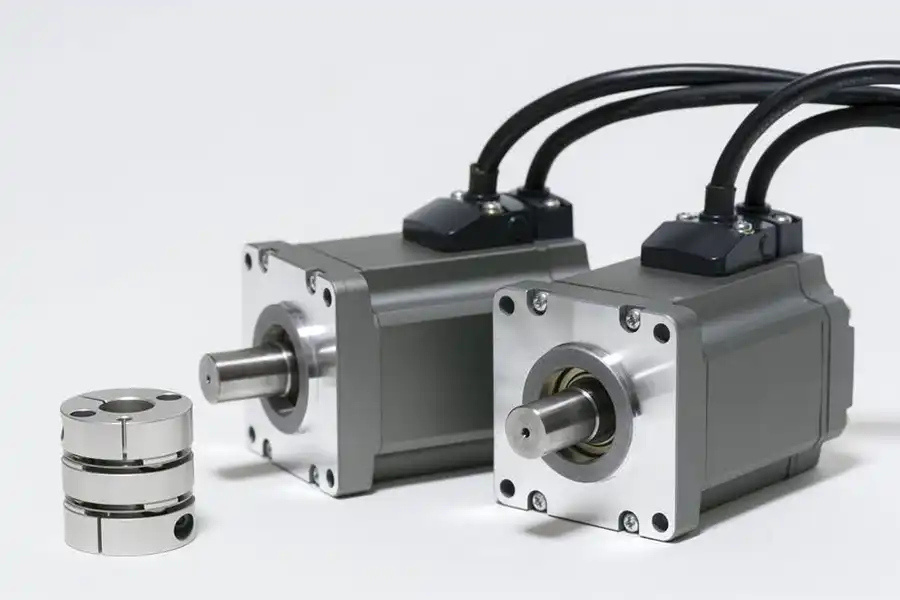

A servo motor is a closed-loop, precision-driven motor system that combines three key components: motor, feedback device, and drive system. In practice, a typical servo motor assembly includes the motor itself (often a brushless DC or AC motor) and an integrated position sensor (such as an encoder or resolver). It is further paired with a servo drive that receives feedback and adjusts power to achieve the commanded motion. This integration enables precise control of position, speed, and torque, making servo motors a popular choice in applications that demand accuracy and repeatability.

AC Servo Motor and Coupling

Servo motors are ready-to-use, plug-and-play devices. They excel at tasks requiring accurate positioning and smooth motion across a wide range of speeds, hence their popularity in industrial automation, CNC machines, and robotics.

The core strengths of a servo motor include:

◉ Precision Control for repeatable accuracy

◉ High Torque and Power Density in compact sizes

◉ Dynamic Response for fast acceleration and deceleration

The Integrated Servo Joint Module by Mosrac takes this technology further! The module combines a servo motor, precision gear (harmonic reducer), encoders, and a brake in one compact unit. Designed for robotics, medical devices, and AI-driven automation, this compact solution delivers servo-like performance while simplifying integration. This makes it easier for engineers to design high-performance systems with minimal compromise.

3. Comparison: Frameless Motor and Servo Motor

1️⃣ Performance & Control

◉ Frameless Motor: Frameless motors rely on direct-drive technology, meaning torque is transmitted straight to the load without intermediate gear trains. This eliminates backlash, compliance, and mechanical wear, resulting in exceptionally smooth motion. Their high pole-count design allows them to deliver high torque at very low speeds, often removing the need for external torque multiplication (e.g., gear reducers). This makes them ideal for robotic joints, surgical robots, and aerospace stabilizers, where smooth, gearless performance is critical.

◉ Servo Motor: This system integrates the motor, feedback device (encoder/resolver), and drive electronics into a closed-loop control environment. The feedback device continuously monitors position, allowing the servo system to correct errors, maintain stable velocity, and sustain accuracy under varying loads. This makes them excellent for CNC machines, packaging systems, and inspection equipment, where high positional accuracy and repeatability are key. The advanced servo motors, like the housed DDR, support precise synchronization in multi-axis systems.

2️⃣ Design & Construction

◉ Frameless Motor: In a frameless motor, only the stator (coil windings) and rotor (permanent magnets) are supplied. There are no housing, bearings, or connectors, giving engineers total freedom to integrate them into the host machine. This not only reduces size and component count but also enables thermal integration, where the machine housing itself becomes the cooling structure. For instance, the U115 series allows torque of up to 50 Nm in a compact 115 mm OD frame, which would otherwise require a much larger housed servo.

◉ Servo Motor: These motors come as fully enclosed, factory-assembled units, typically with IP-rated housings, integrated bearings, and electrical connectors. This makes them plug-and-play devices, robust against dust, vibration, and humidity. While less customizable, their reliability and readiness make them attractive for environments that demand consistent performance with minimal engineering effort. In short, servo motors come ready to install, with the trade-off being that you have less flexibility in form factor; you get the standard sizes and shapes the manufacturer offers.

3️⃣ Integration & Assembly

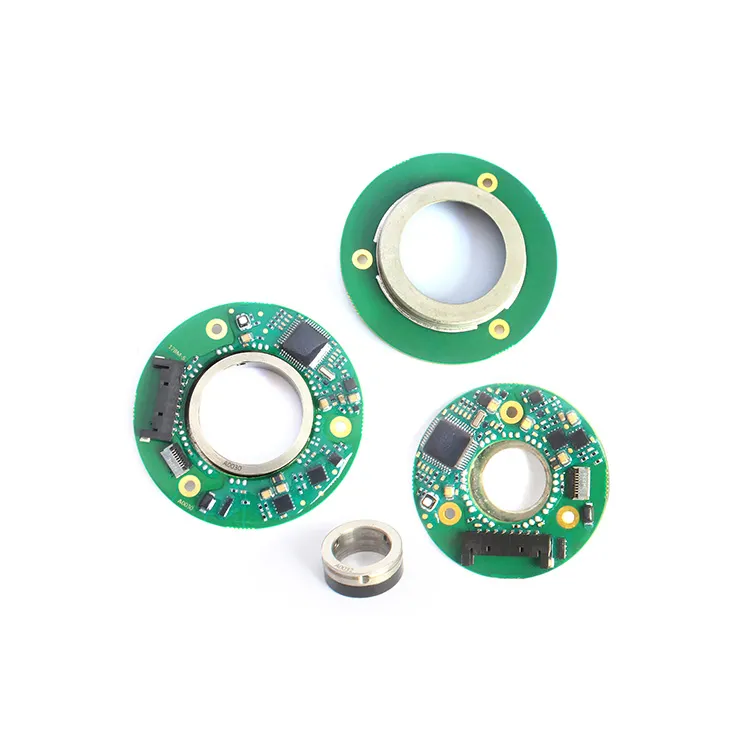

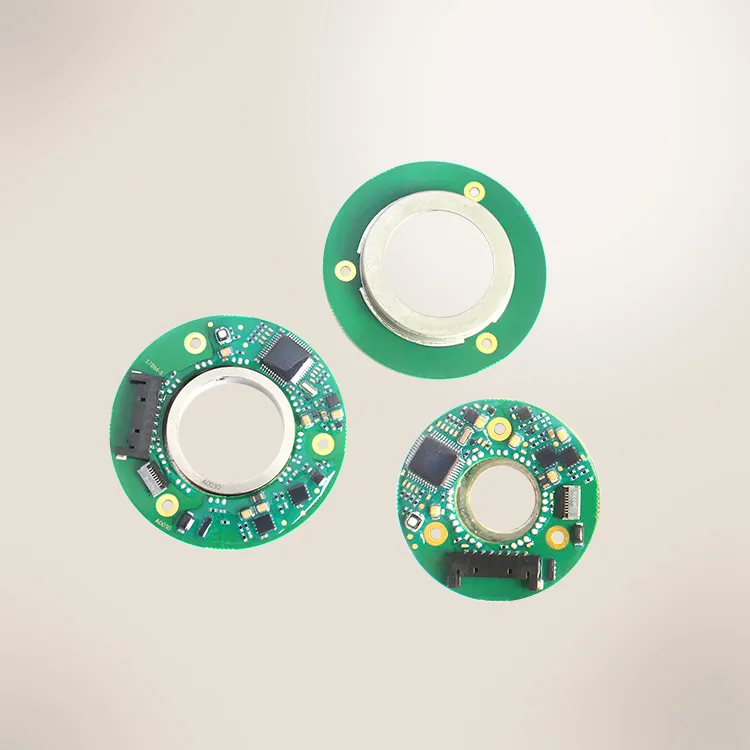

◉ Frameless Motor: Because frameless motors are essentially kits, they require precise alignment of shafts, bearings, and encoders during integration. This adds design effort but pays off in tailored performance and compactness. Mosrac simplifies this with engineer-friendly kits, detailed CAD models, and documentation, allowing OEMs to embed frameless motors seamlessly into robotic arms, gimbals, or medical devices. Additionally, frameless integration supports custom sensor combinations, such as pairing with S-Series and T-Series magnetic encoders for sub-degree precision.

Frameless motors with Magnetic Encoders

◉ Servo Motor: Servo motors, particularly housed DDR models like theFE-80, FE-140, and FI-300, are designed for fast installation. With pre-installed high-resolution encoders (up to 19-bit dual magnetic) and optional reducers, they drastically reduce engineering time. This makes them highly suitable for factories or OEMs prioritizing speed-to-market, where rapid deployment outweighs customizability.

4️⃣ Torque Density & Efficiency

◉ Frameless Motor: Frameless motors excel in torque-to-volume ratio. For example, the Mosrac U115 achieves up to 50 Nm while maintaining a compact profile. By leveraging machine-integrated cooling and optimized copper fill designs, frameless motors minimize resistive losses and maintain lower operating temperatures. This boosts both continuous torque output and operational efficiency, critical in continuous-duty applications like semiconductor processing equipment.

◉Servo Motor: While housed servo motors also provide competitive torque, their added bearings, housings, and seals introduce mechanical losses and limit heat dissipation. Efficiency is slightly lower compared to frameless options, but they compensate with robust environmental sealing and reliable, stable performance. For applications with moderate duty cycles, this trade-off is acceptable and often preferable.

5️⃣ Size & Weight Considerations

◉ Frameless Motor: By removing housings and unnecessary bulk, frameless motors are lighter, slimmer, and more adaptable. This makes them the motor of choice for applications where every gram counts, for example, in robotic exoskeletons, drone gimbals, or aerospace instruments. The compact form factor of the U-Series allows for smaller, more efficient mechanical assemblies.

◉ Servo Motor: The additional housing and bearings make servo motors larger and heavier compared to frameless designs of equal torque output. However, this added weight contributes to ruggedness and environmental protection, which is essential for industrial automation cells, conveyor drives, and outdoor equipment.

6️⃣ Cost & Lifecycle

◉ Frameless Motor: Frameless solutions typically reduce long-term costs due to their maintenance-free, direct-drive architecture (no gears, no wear-prone mechanical couplings). However, they may require higher upfront engineering investment for integration, prototyping, and testing. Over time, their longer service life and energy efficiency deliver a strong ROI, particularly in high-volume OEM applications.

◉ Servo Motor: The housed servo motor comes with higher upfront purchase costs, but lower design costs since integration is straightforward. Their enclosed design ensures a predictable lifespan, especially in industrial settings. For businesses prioritizing time-to-market and reduced engineering complexity, servo motors may offer a better overall cost-benefit balance.

7️⃣ Environmental & Operational Factors

◉ Frameless Motor: Frameless motors excel in custom-sealed or harsh environments, where engineers can design housings that meet particular IP ratings, sterilization standards, or aerospace compliance requirements. Their ability to integrate into washdown-resistant medical housings or vacuum-sealed semiconductor chambers makes them uniquely versatile.

◉ Servo Motor: Housed servo motors come pre-sealed with IP-rated protection, making them ready for industrial environments with dust, oil mist, or humidity, without requiring additional design work. They are the go-to option for factories, packaging lines, and logistics equipment where ruggedness and reliability take precedence over compactness.

Below is the quick comparison of frameless motor vs servo motor:

| Dimension | Frameless Motor (Rotor + Stator Kit) | Servo Motor (Housed, Plug-and-Play) |

| Control | Direct-Drive, Zero Backlash, Smooth Torque | Closed-Loop with Built-In Encoder & Drive |

| Design | Rotor + Stator Only; Fully Customizable | Enclosed Unit with Bearings, Seals, Connectors |

| Integration | Needs Alignment, External Encoder, Custom Housing | Plug-and-Play, Factory Aligned, Fast Setup |

| Torque Density | Very High Torque in Compact Size (e.g., U115 up to 50 Nm) | High Torque, Slightly Less Efficient due to Enclosure |

| Size & Weight | Slim, Lightweight, Shaped to Fit Design | Bulkier, Heavier, but Rugged |

| Cost & Lifecycle | Lower BoM, Low Maintenance, Higher Upfront Engineering | Higher Unit Cost, Minimal Integration Effort |

| Environment | Flexible, Designer Defines Sealing (Vacuum, Washdown, Aerospace) | Pre-Sealed, IP-Rated for Industrial Floors |

| Best Fit | Robotics Joints, Gimbals, Aerospace, Medical Devices | CNC, Packaging, Conveyors, Inspection Systems |

8️⃣ Advantages of Frameless Motors

◉ Ultra-Compact and Lightweight: Frameless motors are as compact as they get for the given torque output. They can be hidden inside mechanisms or structures, enabling very slim and lightweight designs. In robotics, this means thinner joints and lighter limbs; in medical devices, it means smaller surgical tools or imaging equipment. For example, a U25 frameless motor (25 mm OD) can fit into very tight joint spaces where a conventional motor would never go, and larger units like U115 provide high torque density for bigger axes without undue bulk.

◉ Design Freedom and Customization: When you choose a frameless motor, you’re free to tailor the rest of the motor assembly exactly to your needs. You decide on the shaft diameter, bearing type, housing shape, and materials. This can lead to cost savings in volume production (no unnecessary features) and allows integration of functions – your motor housing could also serve as a structural part of the machine, for instance. Mosrac supports this by offering custom torque motor solutions and even one-piece minimum order customization, meaning you can get a frameless motor adapted to your specs without huge order quantities. This level of flexibility is impossible with a fixed standard servo motor.

◉ High Torque Density & Direct-Drive Benefits: Frameless motors achieve very high torque density and can run without gear reduction, which simplifies the system. No gears means zero backlash and smooth motion – critical for precision applications and also beneficial for reducing noise. The direct-drive approach, combined with the ability to integrate cooling (mounting the stator on a heat-conductive machine frame, for example), means frameless motors can sustain performance without the derating that might come from a hot enclosed motor. Overall efficiency can be higher and maintenance lower (since there are fewer moving parts to fail). These advantages make frameless motors the go-to choice for modern designs emphasizing performance and reliability, such as advanced robotic arms, high-speed pick-and-place machines, or gimbal systems.

◉ Modularity in System Design: Since frameless motor kits are modular by nature, creating multi-axis systems or clustered designs is easier. In a compact robot, multiple frameless motors of different sizes (say U25 for small joints and U50 or U85 for larger joints) can be integrated throughout the structure, all working in harmony with the same type of drives and encoders. This modular embedded approach can simplify wiring and improve the aesthetic and ergonomic aspects of the machine (since you don’t have bulky motors sticking out).

9️⃣ Advantages of Servo Motors

◉ Plug-and-Play Simplicity: Servo motors come as complete, self-contained units that you can mount and connect with minimal fuss. The integrated encoder/feedback, pre-aligned bearings, and standard mounting interfaces mean you spend less time engineering the motion system and more time using it. This is ideal when rapid deployment or quick replacement is a priority.

◉ Sealed and Protected: With a fully enclosed housing, servo motors are built to withstand industrial environments. For example, DDR (direct-drive rotary) housed motors are sealed units ready for dusty factory floors or cleanroom settings alike. They offer reliable operation without the user having to implement special protective enclosures.

◉ Integrated Performance: Because the motor and feedback are matched at the factory, servo motors deliver stable, predictable performance across a wide range of speeds and loads. Mosrac’s housed direct-drive motors cover torque outputs from about 1 Nm (on a small FE-80 pancake motor) up to ~35 Nm (on the largest FI-300 series) in standard models. These are excellent for applications like precision rotary tables, indexing machines, or any system that benefits from a turnkey high-torque motor solution with built-in accuracy.

◉ Quick Support and Integration: Using off-the-shelf servo motors means you can leverage the manufacturer’s support, documentation, and accessories. Need a matching servo drive or cable? It’s usually available. This ecosystem can reduce your engineering risk. Additionally, if you anticipate design changes or scaling up the system, it’s often easier to swap one servo motor model for another within a product family than it is to redesign an embedded motor assembly.

4. Global Market Trends & Industry Drivers

The global motor market is evolving rapidly, driven by miniaturization, precision engineering, and sustainable design practices. Industries in the USA, China, and India are leading this transformation, with robotics, medical automation, and advanced manufacturing demanding motors that are smaller, lighter, and more efficient without compromising performance.

Robotic Arm Motors

In robotics, the shift toward collaborative robots, exoskeletons, and service robots requires frameless motors that can be integrated directly into joints, reducing weight while increasing torque density. Similarly, the medical sector is adopting compact motors for surgical tools, diagnostic platforms, and laboratory automation systems where precision and sterility are critical.

Welder Head Robotic Smart Welding Machine

Sustainability is another powerful driver! The companies worldwide are prioritizing energy-efficient, maintenance-free direct-drive systems that reduce lifecycle costs and support eco-friendly product development. Frameless designs in particular allow manufacturers to eliminate unnecessary components, resulting in lighter systems with improved thermal performance.

With a global footprint across 70+ countries, Mosrac ensures consistent supply, engineering support, and branding impact, helping customers scale from prototyping to mass production. Whether for robotics, aerospace, or industrial automation, the trend is clear: the future favors compact frameless solutions for integration and efficient housed servo motors for plug-and-play reliability.

5. How to Choose the Right Motor for Your Project: Frameless or Servo?

Selecting between a frameless motor and a servo motor often comes down to the specific needs of your design. Engineers must weigh factors such as space availability, accuracy requirements, thermal management, integration effort, customization potential, and overall cost.

Frameless Motors and Housed DDR Motors

↪️ When to Choose Frameless Motors?

Best suited for embedding directly into your design, where space and weight are limited.

Ideal for projects requiring high torque density in compact frames, such as robotics joints, surgical devices, or aerospace platforms.

Enables maximum design freedom, allowing integration with custom housings, bearings, and encoders.

Provides enhanced thermal performance by using the host machine’s structure as a heat sink.

↪️ When to Choose Servo Motors?

Perfect for applications where plug-and-play installation is critical.

Provides sealed, factory-assembled protection, making it suitable for industrial environments.

Integrated encoders and optional gear reducers simplify deployment, reducing engineering time.

Reliable choice for rotary tables, packaging systems, and inspection equipment requiring enclosed solutions.

↪️ Custom Engineering Support

Mosrac goes beyond standard products by offering custom solutions, tailored torque/speed options, and even one-piece minimum orders to support flexibility during prototyping.

Their engineering team guides motor selection through design-in and integration, ensuring optimal fit and long-term performance.

Mosrac - Custom Motor Solutions

One of case studies of custom frameless motors

For optimal results, consider consulting our experts to align motor technology with your specific application goals!

6. Conclusion

Both frameless motors and servo motors bring unique strengths to modern engineering. Frameless options excel in compactness, torque density, and design freedom, while servo motors deliver plug-and-play reliability and precise closed-loop control. With decades of expertise, Mosrac provides both solutions, ensuring unmatched precision, reliability, and customization across industries.

To explore the right fit, consult U-Series frameless motors, DDR-housed servo motors, and advanced encoders. Our experts are ready to guide you from motor selection through design-in and seamless integration.

Contact Mosrac today for tailored motor selection support, or request a quotation directly from our product catalog!

7. Frequently Asked Questions (FAQs)

1. What is the difference in performance: frameless motor vs servo motor?

Frameless motors offer higher torque density and design flexibility. Servo motors provide plug-and-play installation with closed-loop precision, ideal for quick integration.

2. Why choose frameless motors for robotics?

Frameless motors embed directly into joints, saving space and weight. Mosrac U-Series delivers compact, high torque density, perfect for advanced robotic and automation systems.

3. How do I start a servo motor comparison for my project?

Compare torque density, size, integration needs, and cost. Mosrac offers both frameless and housed servo solutions tailored to different industries and environments.

4. What is included in a motor selection guide?

A motor selection guide covers torque, speed, thermal management, footprint, and cost. Mosrac experts provide custom torque motor solutions for optimal performance.

5. What makes the Mosrac U-Series Motor unique?

The Mosrac U-Series offers frameless compact motors ranging from 0.025 Nm to 50 Nm. They enable lightweight designs with superior torque density and efficient cooling.

6. Can Mosrac frameless servo motor integration improve efficiency?

Yes. Integrating Mosrac frameless motors, like the U50 series, reduces backlash, enhances cooling, and delivers optimized torque for compact, high-precision applications.