Introduction:

Torque motors play a significant role in industrial applications due to their unique features, such as high torque density, excellent efficiency and low ripples. A torque motor requires a methodical approach for design and control to gain its maximum performance. In design consideration, a torque motor with integrated windings and the same numbers of slots and poles can secure the expected performance through enhancement, leading to a sinusoidal flux density for almost ripple-free torque distribution. The aim of motor control relates to the capacity to handle the performance of electric motors in an accurate and efficient way.

MOSRAC torque motor technology performs as a key solution for the requirements of high productivity, advanced accuracy, and enhanced dynamics of modern machinery. MOSRAC provides great quality frameless direct drive torque motors with an outrunner design and exceptional performance for different applications in industries. It delivers a very precise design, high accuracy, greater overload capacity, excellent torque density, lightweight, and flexibility for industries.

In this article, we will discuss a systematic approach for optimal design and control of a torque motor for the next-generation machine tools while highlighting the key design considerations and specifications of MOSRAC torque motors.

Key Design Aspects of a Torque Motor

With minimum weight and lowest power consumption, the motor structure and geometry are selected outstandingly by maximizing the output torque from the design viewpoint. Some of the design considerations of a torque motor are described below.

1. Number of Poles:

The number of motor poles plays a critical role in choosing the configuration and operations of a motor, affecting parameters, such as speed, torque, and efficiency. Higher pole numbers generate lower magnetic field intensity and minimized output power, while lower pole numbers maximize magnetic field intensity and power output. Motors with higher pole numbers have lower magnetic field variations, creating lower maximum speeds, while those with fewer poles show rapid modifications and higher maximum speed.

2. High Diameter and Small Axial Length:

For torque motors, there are two basic configurations, radial gap and axial gap. Radial gap motors are cylindrical, while axial gap motors are more pancake-shaped. To increase the torque of radial gap motors, the length of the unit increases while the diameter of the axial gap motor increases its torque.

3. Large Hollow Shaft

A hollow shaft motor highlights a unique design with a hole in the center that lets the components pass through the rotational axis. The integrated design allows hollow shaft motors to fit in smaller machinery, having necessary space within the unit. This property delivers extra mounting adaptability. The design of a hollow shaft motor creates an additional torque that helps applications with a greater energy requirement.

4. Winding Structure

The motor winding relates to the winding of the electrical conductor for producing a magnetic field to run the rotors in a torque motor. The design selects the torque, electromagnetic force in the system, electrical resistance, and application. The tighter the winding, the higher the torque.

5. Thermal Management

Thermal considerations are essential for the substantial performance of torque motors in different uses. To enhance torque motor performance and extend the lifetime of motion control solutions, understanding heat generation, choosing the right cooling techniques, and executing best practices for thermal management are necessary. To ensure proper thermal management in torque motor applications, the following best practices need to be considered, such as adequate sizing, proper installation, temperature monitoring, maintenance and inspection.

Motor Torque Control Techniques

Motor torque control is about adapting the torque produced by a motor to attain the expected result in different uses. The main objectives of motor torque control include stable torque output, enhanced motor performance, minimized energy consumption, and prevention of the motor and related machinery from damage.

1. Proportional-Integral-Derivative (PID) Control

There are three components of Proportional-Integral-Derivative (PID) control, such as proportional, integral, and derivative. It is an extensively applied method to handle the torque of a motor. It adjusts the input of the motor so that the expected torque remains precise and steady. The components of PID control improve the system’s sensitivity, making PID control an adjustable and efficient solution for torque management in motors.

2. Field-Oriented Control (FOC)

Field-oriented control (FOC) acts as a key approach used for regulating motor torque, delivering accurate and dynamic control over electric motors. To improve performance and efficiency, FOC lets for separate control of torque and flux by the modification of the motor’s magnetic field with the rotor’s place. This control method allows the stator current vector for coordination with the rotor’s magnetic flux, maximizing energy conversion. Improved torque response and dynamic performance are one of the key advantages of implementing the FOC technique.

3. Feedback Loops and Sensors

Feedback loops and sensors provide essential information to handle the torque effectively. They play a key role in motor torque control by estimating the torque generated by the motor. These sensors can apply magnetic flux change for precise feedback by the motor's speed and location to keep the torque output stable.

Methodologies for Torque Ripple Minimization

Torque ripple acts as a major challenge for torque motors, causing the torque to vary instead of remaining stable, generating vibrations, noise, and lower efficiency. The design and control of a motor play an important role in creating torque ripple. Some important issues, such as uneven magnetic field, cogging, and ineffective commutation, assist very much with the torque ripple issue. Understanding the inherent causes of torque ripple is crucial for developing effective solutions to remove it. Some efficient techniques for reducing torque ripple in torque motors are in the following.

1. Improved Motor Design

Creative designs as skewed rotor slots and advanced magnetic circuits can help reduce torque ripple.

2. Modern Control Algorithms

Executing advanced control techniques, such as Field-Oriented Control (FOC) and Direct Torque Control (DTC), can minimize torque changes and deliver output smoothly.

3. Feedback Techniques

Integrating high-resolution sensors, such as encoders and resolvers, allows for real-time observation and change of the motor’s torque, efficiently minimizing ripple.

Why Choose MOSRAC Torque Motor?

MOSRAC torque motor design including the integration of rotor and stator provides maximum flexibility, lightweight with compact size. It is appropriate for the uses where space is limited to fulfill the industry requirements. Excellent torque, speed, size and temperature for different uses can be attained by our frameless direct-drive torque motors. MOSRAC is prominent for its advancement of special and fully customized torque motors. MOSRAC torque motors contain industry-leading performance and are cost-effective.

A: Types:

Inrunner Frameless Torque Motor:

▪︎ Torque values: 0.025Nm to 50 Nm.

▪︎ Voltage Ranges: 24 V to 48 V or custom-oriented.

▪︎ Outer Diameters: 25 mm to 200 mm or custom-oriented.

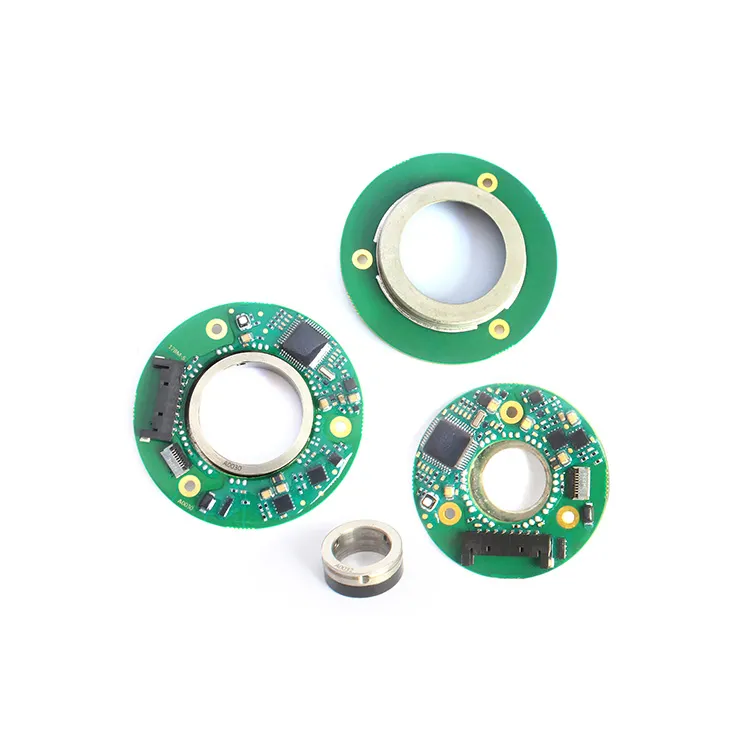

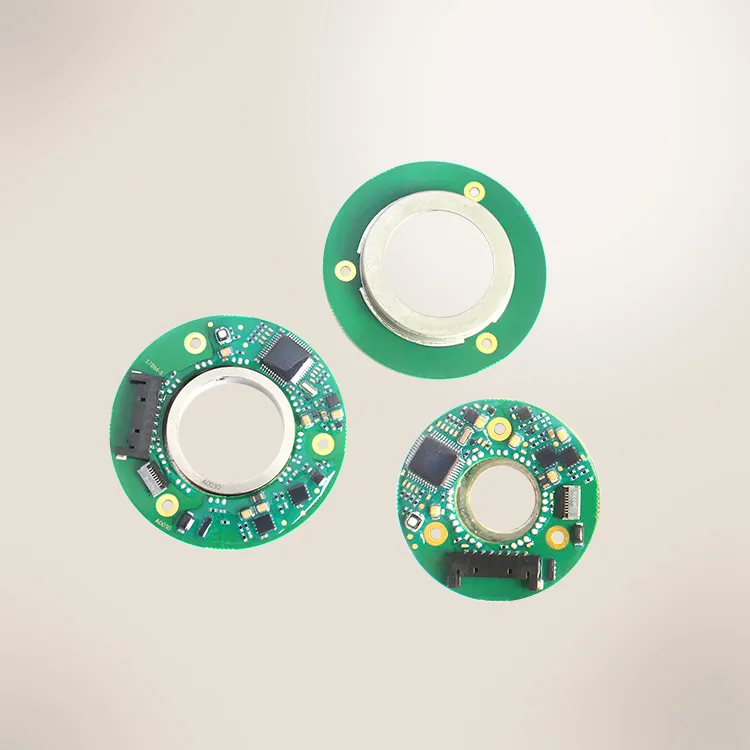

Figure 1: MOSRAC Inrunner Frameless Torque Motor

Outrunner Frameless Torque Motor:

▪︎ Torque values: 0.01Nm to 6Nm

▪︎ Voltage Ranges: 12, 16, 24, 36 and up to 48 V or custom-oriented.

▪︎ Outer Diameters: 14.9mm (0 587"), 22mm (0.866”), 49mm (1.929") up to 485mm (4.291") or custom-oriented.

Figure 2: MOSRAC Outrunner Frameless Torque Motor

B: Features:

▪︎ Integrated Thermal Sensor

▪︎ Various Sizes

▪︎ Low Weight

▪︎ Excellent Precision

▪︎ Very Compact Design

▪︎ High Efficiency

▪︎ Low Cogging

▪︎ High Torque Density

▪︎ Low Maintenance

Conclusion:

The importance of motor torque control and design for achieving optimal performance in various fields, including industrial automation, robotics, and mechatronics, is quite significant. The various methods for controlling torque, such as PID control, sensor less control, field-oriented control (FOC) provide a comprehensive understanding of effective motor torque management. This article gives important information required to handle the challenges of motor torque design and control to drive innovation and improve performance in their applications.

MOSRAC torque motors deliver the customers with various types, compact design, high precision, higher overload capacity, high torque density, and lightweight that will be suitable for different applications in industries. MOSRAC is the best solution for torque motors. MOSRAC is ready to help the customers to choose the appropriate torque motor for different applications.

Any questions or comments about Frameless Motors, Direct Drive Rotary Motors, and Encoders? Contact us at sales12@mosrac.com for sales, technical inquiries, or order samples online today!

Frequently Asked Questions

1. Explain the difference between torque control and speed control.

Torque control relates to keeping the motor’s force accurately while speed control is about keeping the motor’s speed stable. In robots and machines, torque is essential as an accurate force and, for fans and pumps, speed control is necessary as a fixed speed.

2. What are the prime methods used for motor torque control?

Motor torque control applies the techniques like Proportional-Integral-Derivative (PID), sensor less, Field-Oriented Control (FOC), and Direct Torque Control (DTC). Each technique has its own advantages and fits different requirements. The selection relies on the type of the motor and application.

3. Why is Field-Oriented Control (FOC) important for effective torque regulation?

FOC is an important choice for accurate motor torque control that can separate the motor’s flux and torque. This allows FOC control both for accurate torque, making it great for robotics and automation.

4. How can torque control improve the efficiency of a motor?

Applying enhanced algorithms and intensive design can cut losses and keep the motor in the excellent functional range that can make the motor work better and apply lower energy.

5. What are the common techniques for addressing torque ripple in torque motors?

Torque ripple is a challenge for motor control. Apply enhanced control techniques and design advancement to address this challenge to reduce torque ripple to make the motor operation smooth.