U16 to U200 series of Frameless Motors

Introduction

Mosrac has once again raised the bar in high-performance motion control by officially launching its U16 to U200 series of frameless motors. This new product line is designed to serve demanding applications across industrial robotics, aerospace systems, medical devices, collaborative robots (cobots), and precision automation sectors. The series is engineered to provide exceptional torque density, thermal efficiency, and mechanical integration capabilities, making it a game-changer in the world of compact motion systems.

Understanding Frameless Motors

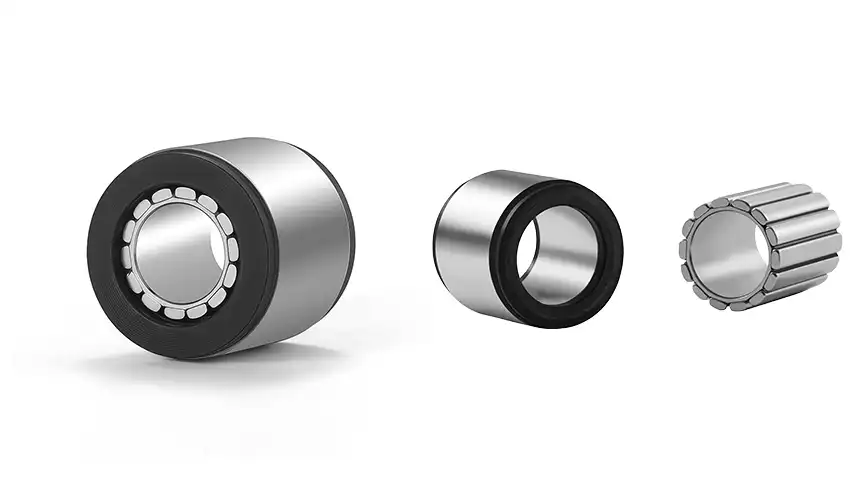

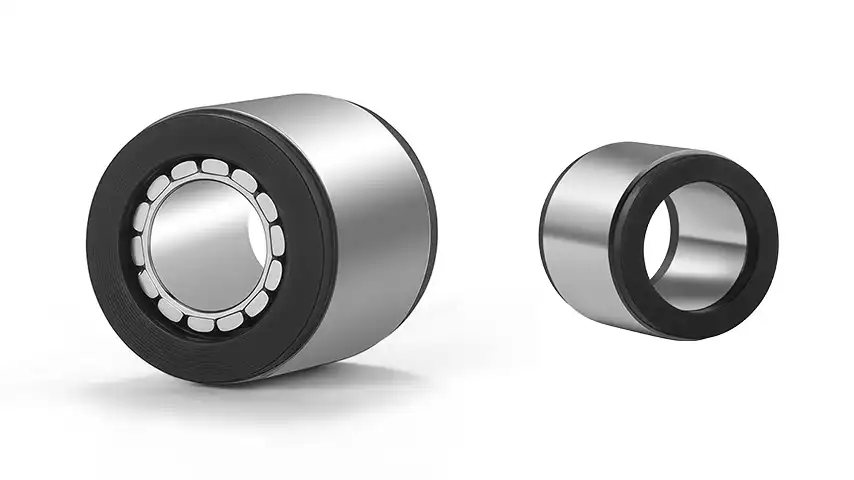

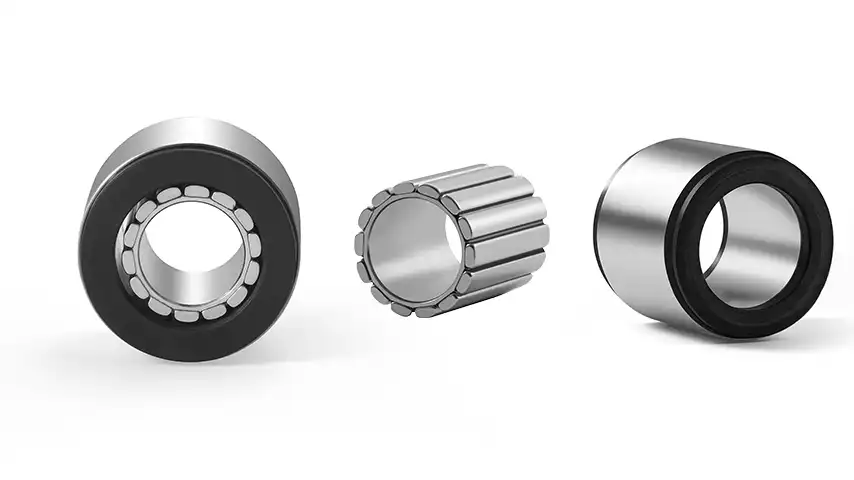

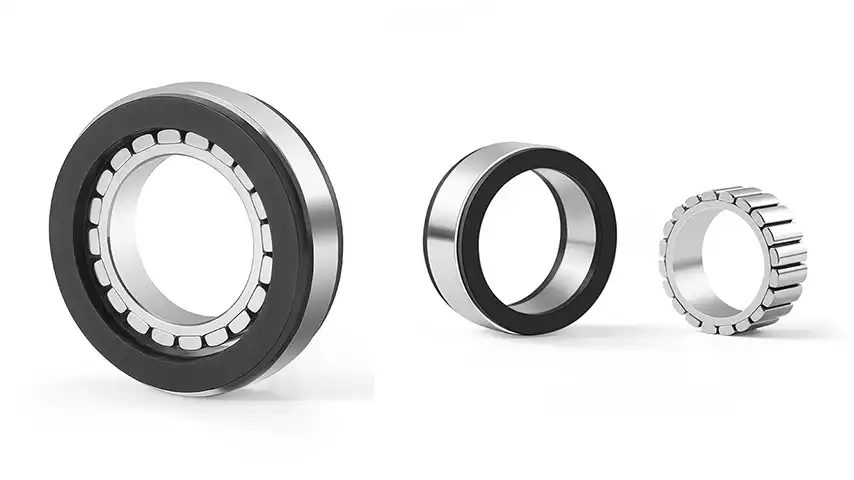

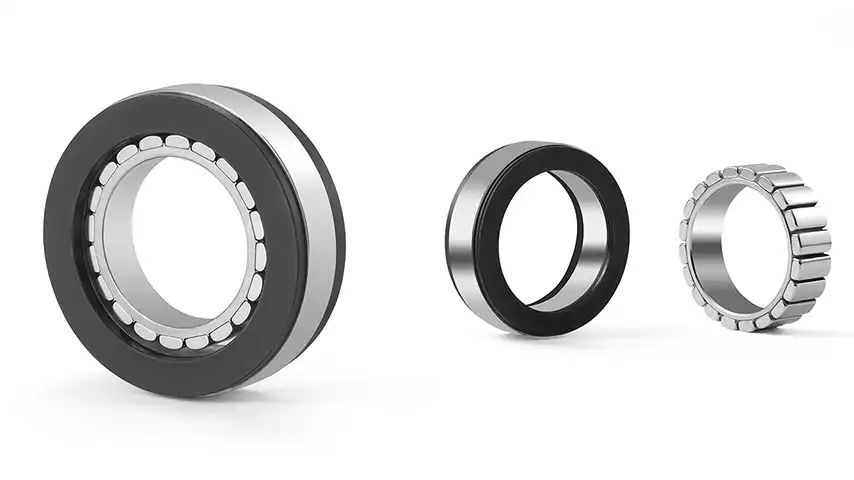

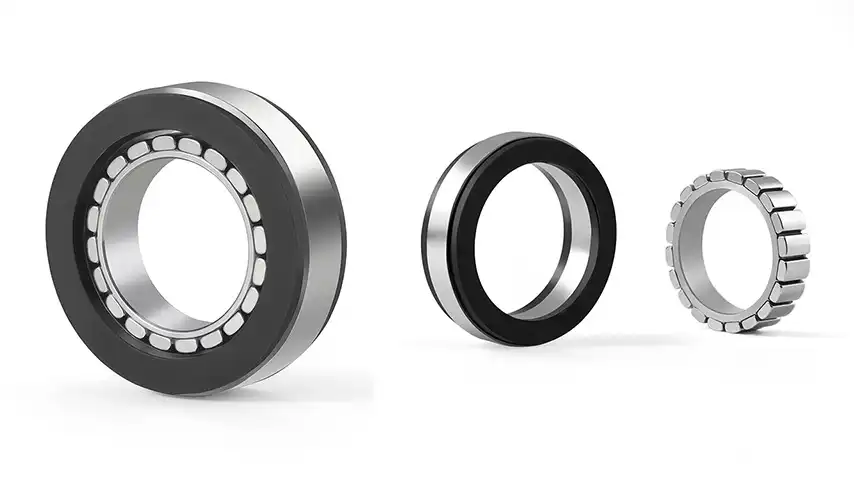

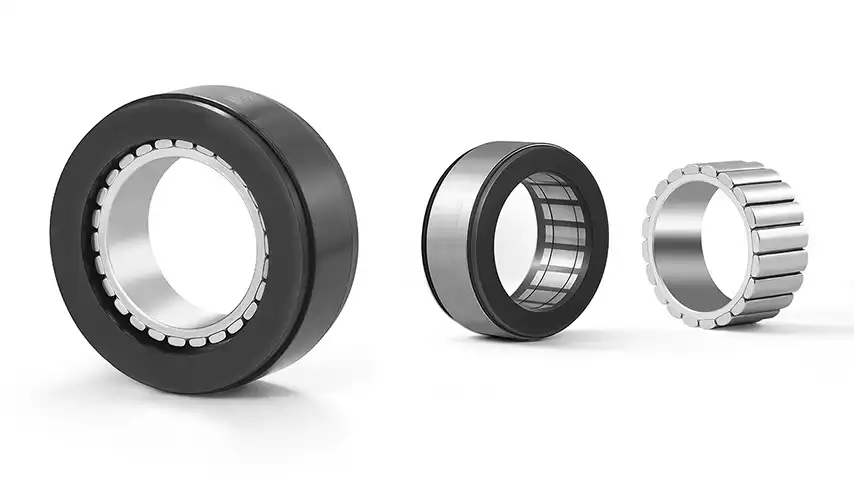

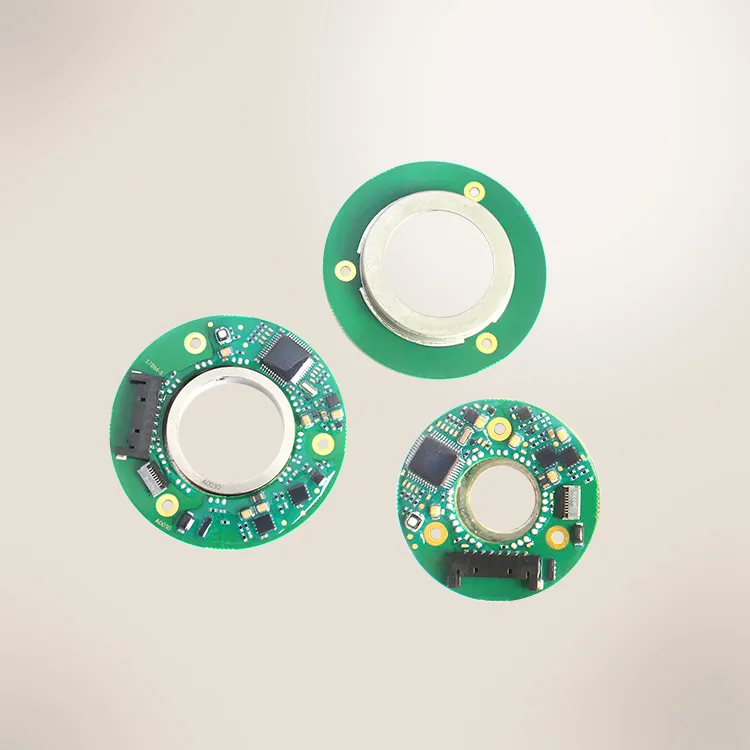

Frameless motors consist of separate rotor and stator components, allowing for direct integration into mechanical assemblies. Unlike traditional housed motors, frameless motors like the Mosrac U-Series allow engineers to integrate the motor directly into the mechanical structure of their application. This delivers high flexibility, weight reduction, and space-saving design without compromising performance.

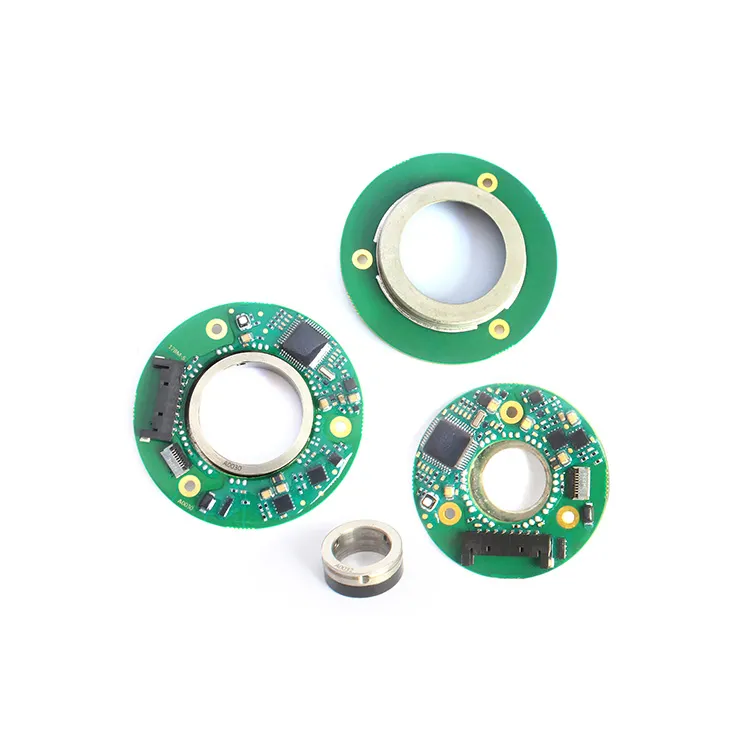

Inrunner Frameless Torque Motors

With rotor and stator supplied separately, the U16 to U200 range enables system designers to customize their integration for optimal performance. Whether embedded into a robotic joint, an exoskeleton actuator, or a high-speed spindle, the frameless design minimizes inertia and maximizes responsiveness.

Recommended Reading: The Frameless Motor: What it is, How it works, & Where to use it

Key Features of Mosrac U16 to U200 Frameless Motor Series

1. Broad Size Range: U16 to U200

The new series spans from 16 mm to 200 mm in outer diameter, enabling a tailored fit for applications of all scales—from compact surgical robots to heavy-duty autonomous vehicles.

2. High Torque Density

Each motor in the series offers an outstanding torque-to-weight ratio, thanks to advanced electromagnetic design and superior lamination materials. The U-Series achieves up to 8 Nm continuous torque/kg, setting a new standard for embedded motor systems.

3. Low Cogging and High Smoothness

Leveraging precision slot-filling, skewed magnets, and optimized stator tooth design, Mosrac frameless motors exhibit minimal cogging torque, ensuring buttery-smooth motion, which is essential for surgical automation, gimbals, and fine robotic manipulation.

4. Integrated Temperature Monitoring

All motors come equipped with built-in NTC thermistors or PT100 sensors, allowing real-time thermal monitoring and smarter control loop protection.

5. Custom Winding Options

With a variety of winding configurations, the U-Series can be optimized for high-speed, high-torque, or low-voltage performance, depending on the needs of the specific application. Mosrac also offers custom winding services for OEMs looking for exact performance profiles.

In frameless inrunner motors, the stator remains stationary and houses the copper windings, while the rotor, equipped with permanent magnets, rotates inside the stator. The windings can be configured in various ways, such as concentrated or distributed windings, each offering different performance characteristics.

U-Series frameless motors offer a range of customization options to tailor performance to specific applications:

▪︎ Custom Windings: Adjustments to winding configurations can optimize for high-speed, high-torque, or low-voltage operations.

▪︎ Pole Counts: Options include 7, 10, or 13 poles, allowing for fine-tuning of torque and speed characteristics.

▪︎ Voltage Ranges: Support for various voltage levels, including 12V, 24V, and 48V, to match system requirements.

▪︎ Thermal Management: Integration of thermal sensors and compatibility with external cooling systems ensures reliable operation under varying thermal conditions.

▪︎ Mechanical Integration: Availability of CAD files and modeling tools facilitates seamless integration into diverse mechanical assemblies.

Recommended Reading: Frameless vs Housed Motors – What’s the Right Choice for You?

Detailed Specifications and Features by Series

▪︎ U16 Series

Outer diameter (OD): 16mm; 1.57-3.14 W | 0.01-0.02 Nm | 1500-3000 rpm | 12 V

One of the latest next-generation frameless motors is the hollow-shaft U16 series stator-rotor kits. This ultra-lightweight, low-inertia, precise low-speed control motor series offers market-leading torque density and maximum design freedom for structurally integrated drive engineering.

▪︎ U19 Series

Outer diameter (OD): 19mm; 12.58-16.77 W | 0.02-0.04 Nm | 4000-8000 rpm | 24 V

U19 Series balances performance and form factor, delivering rapid motion response with minimal vibration. It is frequently integrated into endoscopic tools and gimbal stabilization platforms, where both lightweight design and high-speed capability are essential.

▪︎ U25 Series

Outer diameter (OD): 25mm; 10.5-31.5 W | 0.025-0.075 Nm | 4000-6000 rpm | 24 V

The U25 Series is designed to power robotic wrists and precision grippers. Known for its enhanced torque output despite its small size, this motor supports fine motor movements and quick response times; well-suited for cobots and lightweight automation tools.

▪︎ U38 Series

Outer diameter (OD): 38mm; 31.4-110 W | 0.1-0.35 Nm | 3000-6000 rpm | 48 V

The U38 Series is built to support autonomous sensors and compact autonomous mobile robots (AMRs). This model delivers smooth, low-noise operation and offers superior torque resolution, which is critical for tasks requiring consistent positioning and feedback.

▪︎ U50 Series

Outer diameter (OD): 50mm; 84.89-220.08 W | 0.27-0.7 Nm | 3000-6000 rpm | 48 V

U50 Series is designed for performance in motion systems where both power and compactness matter. It is extensively used in UAV rotors and exoskeleton joints, due to its balanced power-to-weight ratio.

▪︎ U60 Series

Outer diameter (OD): 60mm; 141.48-301.82W | 0.45-0.96 Nm | 3000-7000 rpm | 48 V

The U16 Series is crafted for ultra-compact systems that require pinpoint accuracy and smooth, low-speed control. It is particularly suited for microsurgical robotics and dental devices, where space constraints and delicate handling are critical.

▪︎ U68 Series

Outer diameter (OD): 68mm; 198.07-484.18 W | 0.63-1.54 Nm | 3000-6000 rpm | 48 V

This frameless torque motor is best for light industrial actuators where increased thermal loads and diverse mounting needs must be addressed. It can be optimized for higher thermal capacity and includes customizable mechanical interfaces.

▪︎ U76 Series

Outer diameter (OD): 76mm; 279.82-647.66 W | 0.89-2.06 Nm | 3000-6000 rpm | 48 V

The U76 Series excels in mid-sized applications such as robotic arms and aerospace gimbal systems. Its architecture is direct-drive ready and features a reinforced thermal path to handle continuous duty cycles under load.

▪︎ U85 Series

Outer diameter (OD): 85mm; 380.42-704.78 W | 1.21-2.69 Nm | 2500-6000 rpm | 48 V

The U85 Series is widely used in radar positioning systems and automated packaging machinery. Known for its high-torque winding configuration and advanced cooling interface, this motor is optimized for use in precise angular control and extended operating hours.

▪︎ U94 Series

Outer diameter (OD): 94mm; 496.75-576.92 W | 1.58-3.67 Nm | 1500-5000 rpm | 48 V

This motor series is built for next-generation cobots and precision machining equipment. With its near-zero cogging characteristics and encoder-ready stator design, this model is ideal for tasks that require exceptional smoothness and real-time positional feedback.

▪︎ U115 Series

Outer diameter (OD): 115mm; 943.2-958.92 W | 3.00-6.10 Nm | 1500-5000 rpm | 48 V

U115 Series is a cornerstone for high-speed, repetitive applications like semiconductor wafer handling and industrial printing robotics. This motor offers extremely low inertia, supporting precise and repeatable start-stop cycles.

▪︎ U130 Series

Outer diameter (OD): 130mm; 1048-1509.12 W | 5.00-18.00 Nm | 800-3000 rpm | 220V

The U130 Series is ideal for powering autonomous guided vehicles (AGVs) and computer numerical control (CNC) systems. It is engineered for mid-to-heavy load operations, featuring IP-rated protection and thermal resilience.

▪︎ U160 Series

Outer diameter (OD): 160mm; 1886.4-2012.16 W | 9.00-32.00 Nm | 600-3000 rpm | 220 V

The U160 Series is developed for sensitive and mission-critical systems such as defense-grade optical mechanisms and satellite pointing devices. Built with radiation-hardened materials, the U160 is suitable for systems operating under harsh or space-exposed conditions.

▪︎ U200 Series

Outer diameter (OD): 200mm; 1089.92-1572 W | 13-50 Nm | 300-1200 rpm | 220V

The U200 Series is made for industrial spindles and large-scale gimbal platforms. It delivers extremely high torque output, with options for liquid cooling to support thermal regulation during intensive, continuous operations.

Recommended Reading: Types Of Frameless Motors: Find Out Which Type Is Best For You

Key Engineering Innovations

1. Thermal Optimization

U-Series motors incorporate thermally optimized laminations and epoxy-potted stators to ensure stability even in high-heat environments such as semiconductor fabs and aerospace equipment.

2. High Torque Density

Using high-energy permanent magnets and tight winding geometries, each motor outputs torque levels typically seen in much larger motors, improving space-to-power ratios.

3. Zero Backlash

Eliminating traditional gearboxes, the U-Series promotes true direct drive—ideal for applications where positional accuracy is paramount.

4. Energy Efficiency

Advanced magnetic designs and minimal rotor inertia reduce energy losses, offering better power-to-heat conversion, which is critical for embedded devices.

Application Industries and Use Cases

Robotic Arm 6 Axis Industrial Robot

Robotics

▪︎ Joint actuators in industrial robots

▪︎ End-effectors in surgical and lab automation

▪︎ Autonomous mobile robots for cleanroom or logistics navigation

Aerospace & Defense

▪︎ UAV propulsion and flight stabilization

▪︎ Missile and radar positioning systems

▪︎ Satellite gimbals for orientation and solar panel tracking

Medical Devices

▪︎ Imaging systems that demand smooth motion (MRI-compatible)

▪︎ Surgical robotics for minimally invasive procedures

▪︎ Prosthetics and exoskeletons

Industrial Automation

▪︎ CNC and lathe machines with backlash-free torque

▪︎ High-speed conveyor belts

▪︎ Wafer handling robots in cleanroom settings

Recommended Reading: How To Select a Frameless Torque Motor For a Robot Joint?

Customization Options and Integration Support

1. Tailored Windings

Designs can be adapted for specific voltage, torque, and RPM ranges, including low-voltage battery systems and high-RPM spindles.

2. Thermal Sensors

Motors can be embedded with NTC, PT100, or custom thermal probes, enabling real-time monitoring and integration with external cooling jackets.

3. CAD Support

Mosrac provides ready-to-use 3D CAD files, 2D drawings, and STEP formats for seamless integration into OEM designs.

4. On-Demand Prototyping

Mosrac offers quick prototype turnaround, small batch to OEM/ODM volume production, and expert technical support for non-standard applications—ensuring fast-track prototyping, design validation, and sample runs tailored to your exact performance and integration needs.

Recommended Reading: Case Studies | Mosrac Frameless & DD Motor Company | Torque Motor Manufacturing

Why Mosrac Stands Out?

1. Made-to-Perform Philosophy

Every Mosrac motor is built with a clear understanding of real-world performance metrics. From continuous duty cycles to shock resistance, the company emphasizes reliability over marketing.

2. OEM Partnerships

From semiconductor giants to aerospace pioneers, Mosrac’s products are field-proven across the globe.

3. Full Lifecycle Engineering Consultation

Support doesn’t stop at the sale! Mosrac offers:

▪︎ Pre-sales design reviews

▪︎ Compatibility checks

▪︎ Post-deployment calibration advice

4. Scalability & Supply Chain Strength

With in-house manufacturing and global logistics networks, Mosrac is capable of handling both custom batch production and mass-scale deployment.

Recommended Reading: Best Frameless Torque Motor Manufacturers

The Challenge: High Performance in Harsh Environments

Industries such as aerospace, oil & gas, robotics, and industrial automation often face punishing operational conditions. Once temperatures rise beyond 155°C in confined, unventilated spaces, standard motors begin to fail. In most cases, windings degrade, magnets lose strength, and adhesives break down.

Clients in these sectors came to Mosrac with a clear demand: a high-performance frameless motor that won’t break down under heat. Rather than compromise torque, accuracy, or efficiency, our engineering team set out to reimagine what our series of frameless motors could endure!

Recommended Reading: Frameless Series Motors for Higher Temperatures

Conclusion

With the introduction of the U16 to U200 Frameless DDR Motor Series, Mosrac isn’t just releasing motors—it’s pushing the envelope of what precision motion control can achieve. Whether you're designing next-gen surgical tools, robotic arms, or aerospace-grade gimbals, U-Series offers the performance, reliability, and customization that modern engineering demands.

Speak to our Engineer Today! We’ll help you spec out the optimal motor dimensions, torque constant, and thermal range to meet your application demands.

Frequently Asked Questions (FAQs)

1. What is the Mosrac U-Series Frameless Motor?

The Mosrac U-Series is a range of high-performance frameless direct drive motors, from 16mm to 200mm OD, designed for precision motion in robotics, aerospace, and automation.

2. What makes Mosrac U-Series motors different?

Mosrac U-Series motors offer high torque density, thermal optimization, and zero backlash in a compact, frameless design—ideal for space-constrained, high-precision systems.

3. Can Mosrac frameless motors be customized?

Yes, Mosrac offers custom windings, voltage ranges, thermal sensors, and shaft configurations to meet specific application needs in medtech, defense, and industrial sectors.

4. Which industries use Mosrac U-Series motors?

These motors are widely used in robotics, medical devices, aerospace systems, and semiconductor manufacturing due to their precision, reliability, and compact design.

5. What sizes are available in the U-Series frameless motors?

The Mosrac U-Series includes sizes from U16 (16mm OD) to U200 (200mm OD), offering continuous torque from 0.01 Nm up to 50 Nm, with peak values exceeding 1000 Nm.