U16 Series Brushless Frameless Inrunner Motor

Introduction

At Mosrac, innovation is not just a goal—it’s a guarantee! Known for our cutting-edge frameless direct drive motors and housed DDR motors, we’ve long served industries requiring ultimate precision and performance. Now, we’ve taken it one step further!

Our latest Frameless Series Motors are engineered to perform reliably in high-temperature environments, delivering robust torque output and long-term stability even under extreme thermal stress.

The Challenge: High Performance in Harsh Environments

Industries such as aerospace, oil & gas, robotics, and industrial automation often face punishing operational conditions. Once temperatures rise beyond 155°C in confined, unventilated spaces, standard motors begin to fail. In most cases, windings degrade, magnets lose strength, and adhesives break down.

Clients in these sectors came to Mosrac with a clear demand: a high-performance frameless motor that won’t break down under heat. Rather than compromise torque, accuracy, or efficiency, our engineering team set out to reimagine what our U50 50 mm series frameless servo motors could endure.

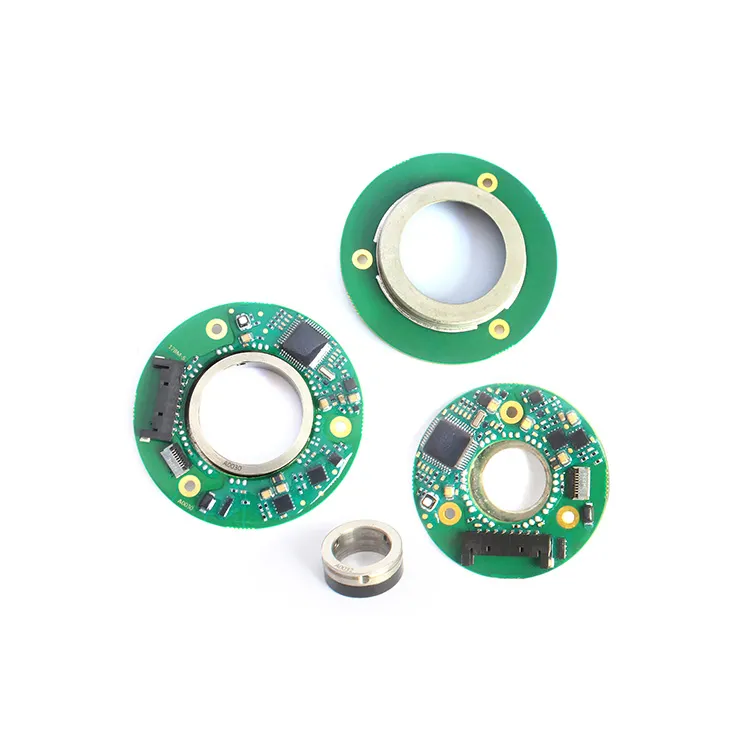

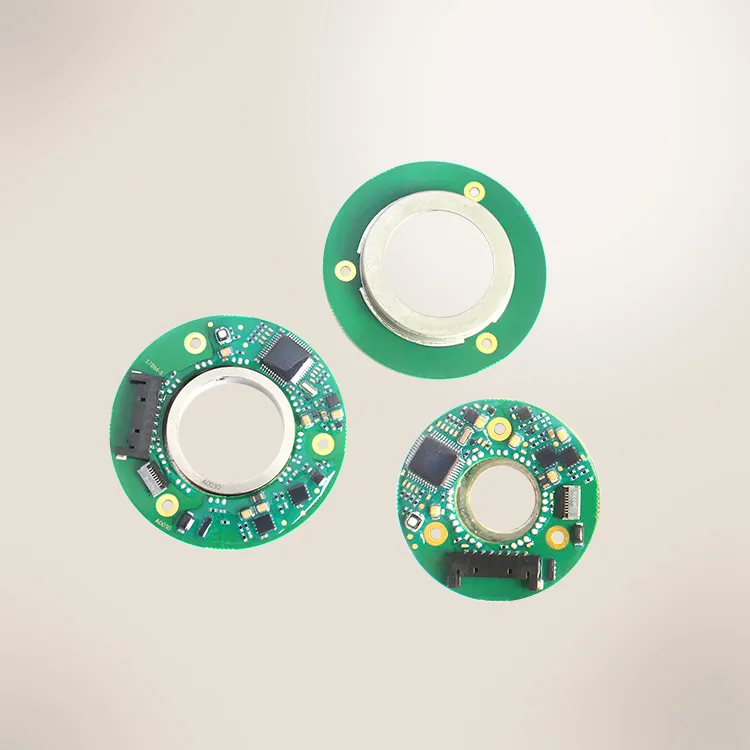

U50 50MM Series Frameless Servo Motor

This motor is highly customizable, built with a 28mm aperture and a 50mm outer diameter directly drives robot joints. The rated torque options include 0.27Nm, 0.42Nm, 0.7Nm, and more…

Redefining Thermal Limits: What Changed in Our Frameless Series?

1. Magnet Upgrade for Thermal Strength

Our previous frameless motors primarily used standard-grade Neodymium magnets. While these offer excellent magnetic strength at room temperature, their magnetic flux density begins to degrade rapidly above 120°C.

For our high-temperature frameless motor, we switched to high-grade Neodymium (NdFeB) magnets with custom thermal stabilization coatings. These rare-earth magnets are carefully selected for:

▪︎ Elevated Curie temperature thresholds

▪︎ Stable magnetic performance up to 150°C

▪︎ Reduced risk of thermal demagnetization

This preserves high torque density without increasing motor volume—an essential factor for space-constrained systems in robotics and aerospace!

2. High-Temperature Windings: Re-engineered from the Core

Typical insulation in stator windings becomes brittle or softens at elevated heat levels. Our engineering team developed a custom winding solution using polyimide-based insulation systems rated for up to 155°C.

This advanced winding material:

▪︎ Maintains dielectric strength under thermal cycling

▪︎ Prevents shorts or internal degradation

▪︎ Ensures long motor life, even in 24/7 duty cycles

The result?

Frameless stators that can run hot, without burning out.

3. New Encapsulation & Adhesive Systems

Heat doesn’t just impact the electrical system; mechanical integrity is also at risk. Our standard encapsulants and adhesives were replaced with high-temperature-resistant bonding compounds rated beyond 155°C.

These encapsulants:

▪︎ Improve thermal conductivity

▪︎ Prevent delamination

▪︎ Secure coil placement under shock and vibration

Our frameless rotor-stator assemblies now exhibit minimal drift or thermal expansion issues, ensuring that tight mechanical tolerances are maintained.

4. Optimized Core Design for Better Thermal Dissipation

Beyond material upgrades, we optimized the core geometry for better heat dissipation. Advanced FEA simulations allowed our engineers to:

▪︎ Reduce thermal hotspots

▪︎ Improve airflow pathways

▪︎ Balance magnetic flux across wider temperature gradients

Combined with improved lamination materials, our high-temp frameless motors now support sustained duty in thermally active applications without needing external cooling systems.

Real-World Validation: Tested, Verified and Trusted

Before launch, our HT-rated Frameless Series Motors underwent rigorous validation in our in-house thermal cycling and shock test chambers. Conditions included:

▪︎ 155°C continuous operation

▪︎ Rapid thermal rise/fall cycles

▪︎ Vibration and axial shock exposure

Results?

Zero winding insulation breakdown, no magnet degradation, and again, zero adhesive failure. Just 100% motor integrity under heat stress! These motors are now in active deployment in downhole drilling systems, military-grade UAVs, and semiconductor wafer handling robots—where heat is a constant adversary.

The Applications: Designed for Tomorrow’s Demands

Our high-temperature frameless motors are a game-changer for several industries:

| Industry | Application |

| Oil & Gas | Downhole drilling tools, MWD, LWD systems |

| Aerospace | Actuators in jet engines, environmental control units |

| Robotics | Arm joints in welding robots, AGVs in foundries |

| Semiconductor | Wafer handling and metrology systems |

| Defense Systems | Ruggedized weaponry, radar positioning systems |

Each use case demands compact, lightweight, and thermally resilient motor systems—exactly what Mosrac delivers!

Technical Specifications at a Glance

Mosrac builds frameless motors for precision and thermal endurance across varied applications.

The U115 Series offers a compact 115 mm outer diameter and delivers 3–6.1 Nm torque at 1500–2500 rpm, with power ratings up to 958.92 W.

The U130 Series, slightly larger at 130 mm in diameter, provides 5–18 Nm torque at 400–800 rpm and up to 754.56 W power.

For higher torque needs, the U160 Series features a 160 mm diameter and delivers 9–32 Nm torque at 200–500 rpm with power ratings up to 670.72 W.

Each series balances size, torque, and thermal performance for demanding environments.

Why Choose Mosrac?

Unlike off-the-shelf solutions, our frameless motor systems are tailored to your specific thermal, spatial, and torque requirements.

Frameless motor kits from Mosrac

Here's what sets Mosrac apart:

▪︎ Precision Engineering: Built with micron-level tolerances

▪︎ Modular Integration: Easily embedded in your mechanical structure

▪︎ Thermal Efficiency: Rated for 180–155°C without auxiliary cooling

▪︎ Custom Support: Work directly with our motor design engineers

▪︎ Proven Quality: ISO 9001 & ISO 13485 certified manufacturing

We don’t just ship motors. We build performance into your system! Reduce motor costs with our proven optimization techniques, like material alternatives and supply chain optimization. So, power your application with personalized, high-quality standard or custom motors for every need.

Recommended Reading: How To Select a Frameless Torque Motor For a Robot Joint?

Conclusion

Frameless motors built for high temperatures are a necessity in modern mission-critical systems. With materials science innovations, smart thermal design, and real-world testing, Mosrac delivers motors you can rely on—even when the heat is on!

Speak to our Engineer Today! We’ll help you spec out the optimal motor dimensions, torque constant, and thermal range to meet your application demands.