Learn how encoders work, explore key types, compare performance metrics, and discover how precision encoders enhance robotics, automation & industrial systems!

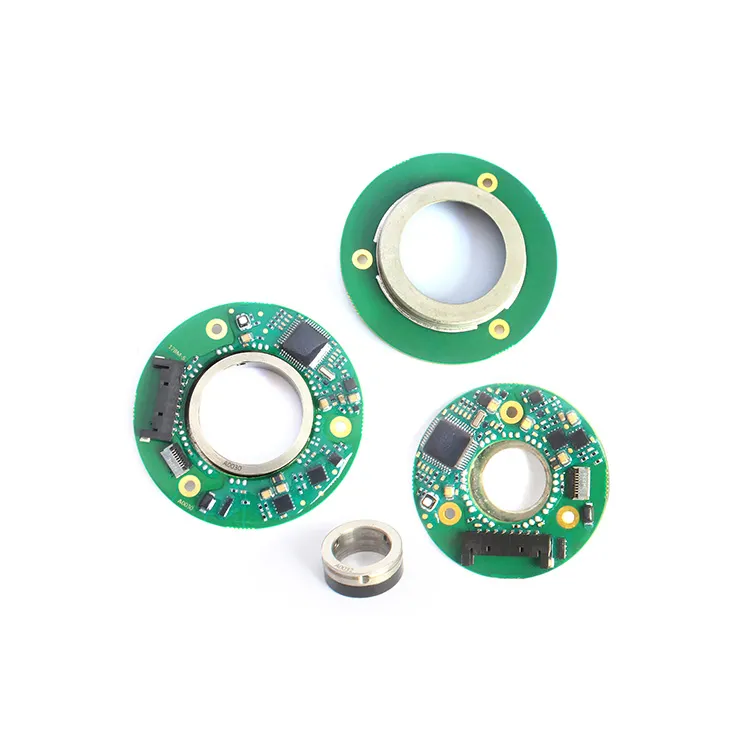

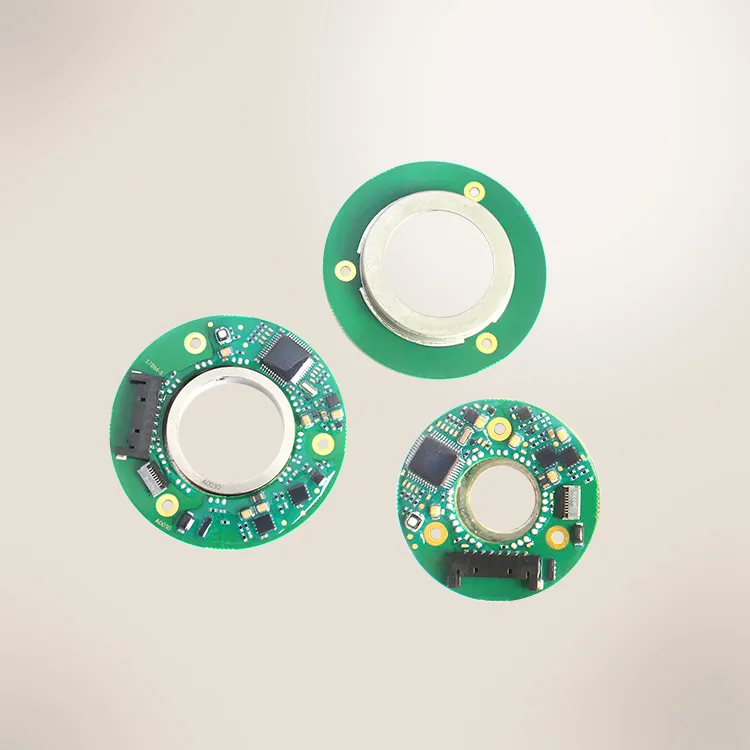

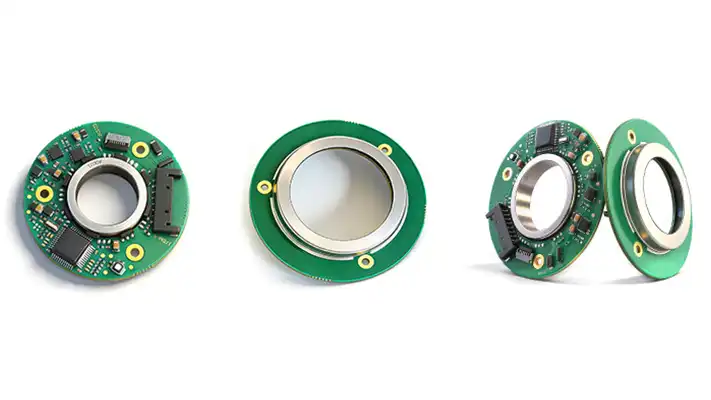

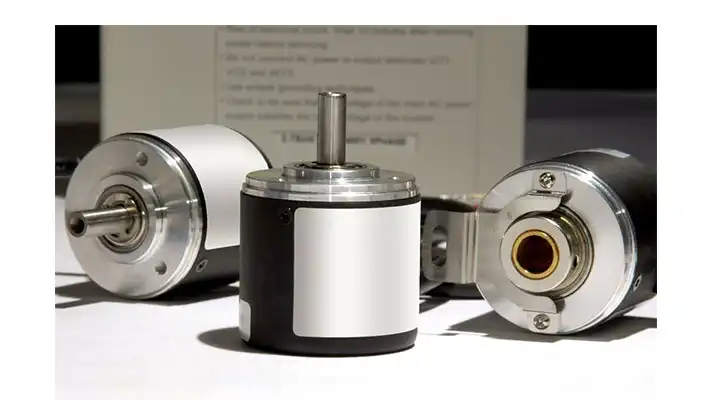

17-bit & 24-Bit High-Resolution Magnetic Absolute Rotary Encoder

What Is an Encoder?

An encoder is a sensing device that converts information from one format or code to another, typically transforming physical motion or position into a digital signal. This signal can then be interpreted by a control system to determine critical information about the movement, including position, speed, and direction.

Encoders are a critical component in closed-loop control systems, where accurate position feedback is essential for stable and efficient operation. They are widely used in BLDC motors, servo drives, robotics, cobots, and industrial automation, enabling precise commutation, smooth motion, and repeatable positioning. Without reliable encoder feedback, modern motion systems cannot achieve the accuracy, responsiveness, or safety required in high-performance applications.

Absolute Rotary Magnetic Encoders | High Resolution and Accuracy

Mosrac designs and manufactures high-precision encoder solutions trusted globally across robotics, automation, and industrial motion-control systems. In this article, we’ll discuss how encoders work, highlight real-world use cases, and explore precision encoder technologies.

Why Encoders Matter in Modern Motion Control Engineering?

In modern motion control engineering, encoders are crucial for automation systems because they provide the precise, real-time feedback required to achieve high levels of accuracy, repeatability, efficiency, and safety. They act as the "eyes" of a machine, translating physical movement into digital signals that control systems can interpret and act upon.

Magnetic Encoders by Mosrac

Let’s explore why encoders are indispensable:

● Enabling Precise Closed-Loop Motor Control

Encoders provide real-time feedback on position, speed, and direction, enabling controllers to continuously correct motor output. This feedback is essential for BLDC and servo motors using field-oriented control (FOC), where accurate rotor position minimizes commutation error and torque ripple.

● Improving System Stability and Dynamic Response

High-resolution, low-latency encoder signals increase control-loop bandwidth. This reduces overshoot, oscillations, and settling time, enabling faster and more stable motion in high-speed automation and robotics.

● Ensuring Repeatability in Automated Manufacturing

Encoders deliver consistent positional reference across millions of cycles. This repeatability is critical for CNC machines, pick-and-place systems, and packaging lines where micron-level errors accumulate into quality defects.

● Enabling Safety-Critical Operations

Absolute encoders retain the actual position after power loss, enabling deterministic restarts and fault detection. They are integral to functional safety architectures (e.g., ISO 13849, IEC 61508) in collaborative robots and industrial machinery.

● Enhancing Robustness in Harsh Industrial Environments

Magnetic and inductive encoders provide reliable feedback in dust, oil, vibration, temperature extremes, and EMI — conditions where optical systems often fail — ensuring uptime in demanding applications.

● Supporting High-Performance Robotics and Automation

Precise feedback enables smooth torque control, joint synchronization, and compliant motion. This is vital for cobots, multi-axis robots, and AGVs requiring accuracy, responsiveness, and safety.

● Improving Energy Efficiency and System Optimization

Accurate feedback allows motors to operate closer to optimal torque-speed points, reducing current draw, heat losses, and wear. It also enables condition monitoring and predictive maintenance.

● Facilitating Miniaturization and Integrated Mechatronics

Compact kit and modular encoders reduce mechanical stack-up and enable dense, integrated designs — particularly in frameless motors — improving stiffness, dynamics, and overall system performance.

Recommended Reading: Motor Encoders - Types, Features, Advantages, Applications, and Choosing the Right One

How Encoders Work?

The encoders operate by converting physical (mechanical) motion into a readable format (electrical signals). Once a shaft rotates or a linear element moves, the sensing element (magnetic, inductive, optical, or capacitive) of the encoder detects changes in a physical field (magnetic flux, light interruption, or electromagnetic coupling). These changes are converted into electrical signals, which are then conditioned and output as digital data or pulses for the control system.

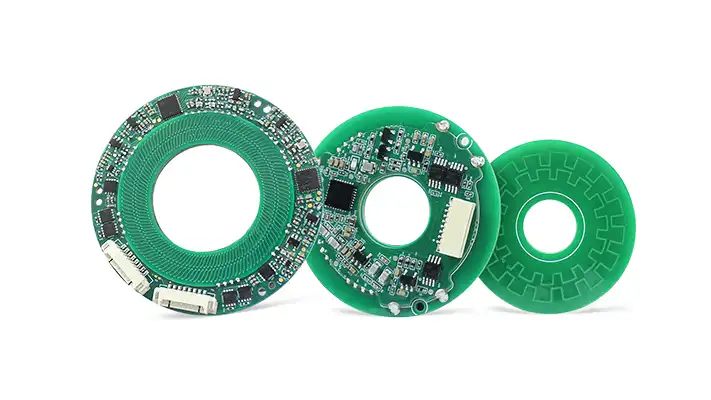

Inductive Rotary Absolute Encoders by Mosrac

For instance, in a rotary encoder, the rotation of a shaft is detected by the sensing element, which then generates a corresponding electrical signal. This signal is processed and converted to a digital format that can be interpreted by a control system, enabling precise monitoring and control of mechanical movement. The connectors transmit electrical signals between the encoder and the controlling device, while couplings isolate the encoder from the shock and vibration of the machine.

The encoder consists of three key components at a functional level:

● Sensing Element: Responsible for detecting the physical motion and converting it into an electrical signal.

● Signal Converter: Physically translates the detected movement into an electrical signal.

● Output Interface: Processes the raw sensor signal and sends it to the control system.

The key performance parameters define how effectively an encoder represents motion.

● Resolution indicates how finely position can be measured and is often expressed as counts per revolution (CPR) for rotary encoders. Higher CPR enables finer positional control.

● Accuracy describes how closely the measured position matches the true mechanical position.

● Latency refers to the delay between mechanical movement and signal output, critical in high-speed control loops.

Together, these factors determine an encoder's suitability for precision motion control, robotics, and high-dynamic industrial systems.

Different Types of Encoders

Encoders can be classified in several ways — by sensing principle, signal/output type, mechanical structure, and measurement method.

Brushless DC Motor with Integrated Encoder and Industrial-Grade Wiring

Below is a clear, technical breakdown used in modern motion-control engineering:

1. Magnetic Encoders

Magnetic encoders use Hall-effect or magneto-resistive sensors to detect changes in a magnetic field caused by shaft movement. They offer high EMI immunity, long service life, and stable performance.

S-Series Magnetic Encoders provide compact size, high resolution, and industrial-grade robustness. They deliver 17-bit resolution and ±0.05° accuracy in a compact 6–7 mm design, making it ideal for motor housings or gearboxes. For higher precision, the T-Series Magnetic Encoders offer 24-bit dual-axis resolution and ±0.01° accuracy in a compact form factor, making them ideally suited for robotic joints and medical devices.

2. Inductive Encoders

Inductive encoders operate using eddy-current effects and electromagnetic field variation rather than magnets or optics. This makes them highly durable and immune to dust, oil, vibration, and temperature extremes.

Inductive Encoders by Mosrac deliver high-accuracy, reliable feedback in harsh environments. The family includes:

● C-Series Inductive Rotary Encoders: Ultra-thin, lightweight encoders with a large hollow shaft and non-contact design for compact spaces and robot joints; suitable for position feedback and commutation sensing in frameless motors.

● D-Series Inductive Rotary Encoders: Dual-system encoders with redundant position detection and output channels for higher reliability in critical motion axes.

● DP-Series Inductive Rotary Encoders: Dual-rotor design within an ultra-thin form factor, enabling high precision and low power consumption for space-constrained automation applications.

3. Optical Encoders

Optical encoders use an LED, a photodetector array, and a precision code disc to generate position signals. They offer very high resolution and accuracy, making them suitable for precision applications.

However, they are sensitive to dust and contaminants. Optical encoders are commonly used in CNC machines, laboratories, and clean-room automation systems.

4. Capacitive Encoders

Capacitive encoders measure position by detecting changes in capacitance between patterned electrodes. They are compact, lightweight, and consume very little power.

While their accuracy is moderate compared to optical systems, they are cost-effective and reliable for short-range motion sensing. These encoders are often used in small consumer devices and low-power electronics.

5. Analog Encoders

Analog encoders output a continuous voltage or current signal proportional to position or angle. Instead of digital pulses, they provide smooth analog feedback that is easy to interpret with basic control electronics.

They are suitable for simple position-sensing applications but are more susceptible to noise and signal degradation over long cable lengths.

6. Digital Encoders

Digital encoders transmit position data using serial communication protocols such as SSI, BiSS-C, SPI, or I²C. They offer high noise immunity, precise data transfer, and support long cable runs. Digital encoders are widely used in modern motion control systems where accuracy, speed, and EMI resistance are critical requirements.

7. Shaft Encoders

Shaft encoders feature a mechanical shaft directly coupled to the rotating element being measured. They are easy to install and widely available in a range of sizes and resolutions. Shaft encoders are commonly used in motors, conveyors, and industrial machinery, but mechanical coupling can introduce wear or alignment issues over time.

8. Hollow-Shaft Encoders

Hollow-shaft encoders mount directly over a motor or machine shaft without the need for couplings. This simplifies installation, improves alignment, and reduces mechanical wear. They are widely used in industrial automation and servo systems where compact installation and reliable shaft alignment are essential for long-term accuracy.

9. Kit Encoders (Modular)

Kit encoders consist of a separate sensor module and a rotor magnet mounted directly on the shaft. This design enables extremely compact integration and minimal mechanical stack-up. Kit encoders are ideal for robotics and frameless motors. The encoders by Mosrac integrate seamlessly with frameless torque motors for high-density motion designs.

10. Through-Bore Encoders

Through-bore encoders feature a large central opening that allows cables, shafts, or other mechanical components to pass through. They are commonly used in large machinery and automation systems where traditional shaft encoders are impractical. This design simplifies mechanical integration while maintaining accurate rotational position feedback.

11. Rotary Encoders

Rotary encoders measure angular position, speed, and direction of a rotating shaft. They are the most common encoder type used in motors, robotics joints, and automation axes. Rotary encoders support both absolute and incremental outputs and are essential for precise rotational motion control in industrial and robotic systems.

12. Linear Encoders

Linear encoders measure displacement along a straight path rather than rotation. They provide direct position feedback without mechanical conversion, improving accuracy. Commonly used in CNC machines, metrology equipment, and linear stages, they enable high-precision positioning in applications requiring micron-level linear motion control.

13. Multi-Turn Encoders

Multi-turn encoders track both the angular position within a single rotation and the total number of full rotations. This allows absolute position measurement over long travel ranges. They are ideal for articulated robots, servo presses, lifting systems, and elevation mechanisms where position must be retained after power loss.

14. Single-Turn Encoders

Single-turn encoders measure angular position within one complete revolution only. They reset after each rotation and are simpler than multi-turn designs. These encoders are often used in compact, low-power systems such as IoT devices, actuators, and battery-powered applications where full rotation counting is unnecessary.

15. TTL encoder/BISS encoder

TTL encoders output digital square-wave signals for short-distance, high-speed communication. BiSS encoders use a bidirectional serial interface, offering high resolution, low latency, and strong EMI resistance. BiSS is widely adopted in high-performance motion control and robotics, where fast, deterministic data transfer is required.

16. Robotic Encoders

Robotic encoders are optimized for joint-level position feedback in multi-axis robots. They emphasize compact size, high resolution, low latency, and robustness. Interfaces such as CANopen, EtherCAT, RS-422, SPI, and BiSS enable synchronized multi-axis control, making them essential for industrial robots and cobots.

17. Absolute Encoders

Absolute encoders assign a unique digital code to each position, allowing the system to know the exact shaft angle immediately after power-up. They eliminate homing routines and support safety-critical applications. Absolute encoders are widely used in robotics, automation, and machinery where deterministic position recovery is required.

18. Incremental Encoders(Quadrature Encoder)

Incremental encoders generate pulse signals as the shaft moves, typically using A and B channels for direction detection. Position is determined by counting pulses from a reference point. They are cost-effective and commonly used for speed measurement and relative positioning in motors and industrial automation systems.

19. Servo Motor Encoder

Servo motor encoders provide high-resolution feedback required for precise torque, speed, and position control. They enable closed-loop operation in servo drives, supporting smooth motion and fast response. These encoders are critical in robotics, CNC machines, and automation systems, demanding high accuracy and dynamic performance.

20. Angle Encoder

Angle encoders are explicitly designed to measure angular position with high precision, often over limited rotational ranges. They are used in steering systems, gimbals, robotic joints, and positioning mechanisms. High-resolution angle encoders ensure accurate alignment, orientation, and control in precision motion applications.

Recommended Reading: 14 Different Types of Encoders for Various Types of DC Motors

Choosing the Right Encoder: Step-by-Step Engineering Checklist

Selecting the correct encoder requires aligning application demands, environmental constraints, and control-system requirements.

Industrial Incremental Encoders

The following checklist reflects how motion-control engineers evaluate encoder suitability in real-world systems.

Step 1 — Define Your Application

Start by identifying the primary function of the encoder within the system:

● Robotics and Cobots: joint position, torque control, synchronization

● Motor Control: rotor position and speed feedback for BLDC or servo drives

● CNC and Precision Machinery: micron-level positioning and repeatability

● Industrial Automation: reliability and uptime over long duty cycles

The application determines whether high resolution, absolute position, or fast dynamic response is the priority.

Step 2 — Evaluate Environmental Conditions

The operating conditions directly influence encoder technology selection:

● Dust, Oil, and Moisture: favor non-optical solutions

● High Temperature or Vibration: requires robust sensing principles

● Electromagnetic Interference (EMI): demands noise-resistant designs

In harsh industrial environments, magnetic encoders and inductive encoders outperform optical solutions in long-term reliability.

Step 3 — Choose Based on Sensing Technology

Match sensing principle to performance and durability needs:

● Optical Encoders: highest precision in clean, controlled environments

● Magnetic Encoders: strong balance of accuracy, robustness, and EMI immunity

● Inductive Encoders: extreme durability for heavy-duty and contaminated environments

This step often determines the system's overall reliability.

Step 4 — Match Interface Requirements

Ensure compatibility with the motor drive or controller:

● SPI / SSI: simple, widely supported serial communication

● BiSS-C: high-speed, deterministic, ideal for precision motion control

● CANopen / EtherCAT: real-time industrial networks for robotics and automation

Interface choice affects latency, update rate, and system integration complexity.

Step 5 — Compare Product Specs

Evaluate quantitative performance parameters:

● Resolution (CPR or bits)

● Accuracy and Repeatability

● Maximum Mechanical Speed

● Latency and Update Rate

● MTBF and Operating Lifetime

Balancing these metrics ensures optimal performance without over-specification.

For application-specific guidance or custom solutions, Mosrac engineers can help match the right encoder technology to your motion system requirements.

Common Industry Applications for Encoders

Encoders are fundamental to a wide range of industries where precise motion feedback, reliability, and safety are critical. Their role varies by application, but accurate position and speed sensing remain central across all sectors.

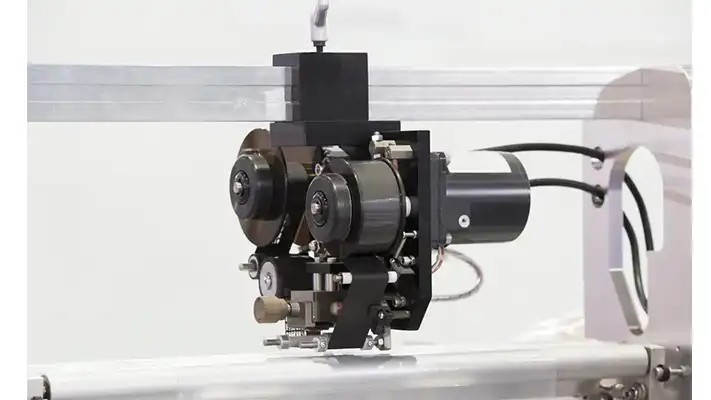

Magnetic Encoders used in Industrial Production Line

1. Robotics & Cobots

In robotic systems, encoders enable precise joint articulation, smooth motion, and coordinated multi-axis control. High-resolution position feedback is essential for accuracy, repeatability, and safe human-robot interaction. The compact kit encoders, such as S-Series magnetic encoders, are especially suited for robotic joints due to their small footprint and seamless integration with frameless motors.

2. AGVs, AMRs, and Mobile Robots

Autonomous and mobile robots rely on encoders for wheel-speed sensing, odometry, and navigation accuracy. Reliable feedback ensures precise path tracking, obstacle avoidance, and stable motion, even in electrically noisy industrial environments.

3. Industrial Automation

Encoders are widely used in packaging machines, textile automation, and conveyor systems, where consistent speed and position control are required over long operating cycles. In food-processing and wash-down environments, optical encoders are generally avoided, while magnetic and inductive encoders are preferred due to their resistance to contamination and moisture.

4. Aerospace & Defense

These applications demand encoders capable of operating under high vibration, shock, and extreme temperature variations. Inductive encoder technologies offer excellent thermal stability and mechanical robustness, making them suitable for flight control systems, actuators, and defense-grade motion platforms. The inductive encoder solutions at Mosrac are engineered to meet such demanding conditions.

5. Medical Devices

In medical equipment, encoders support clean, precise, and repeatable motion, particularly in surgical robotics and diagnostic systems. High accuracy and low latency enable backdrivable robotic mechanisms, ensuring smooth, controlled motion and enhanced patient safety.

By leveraging the capabilities of encoders, modern systems can achieve higher levels of precision, efficiency, and reliability, driving productivity and innovation in manufacturing processes.

Recommended Reading: Single-Turn vs. Multi-Turn Encoders: The Lean Guide

Future Trends in Encoder Technology

The encoder technology continues to evolve alongside advances in automation, robotics, and intelligent motion systems. Several key trends are shaping the next generation of encoder design and integration.

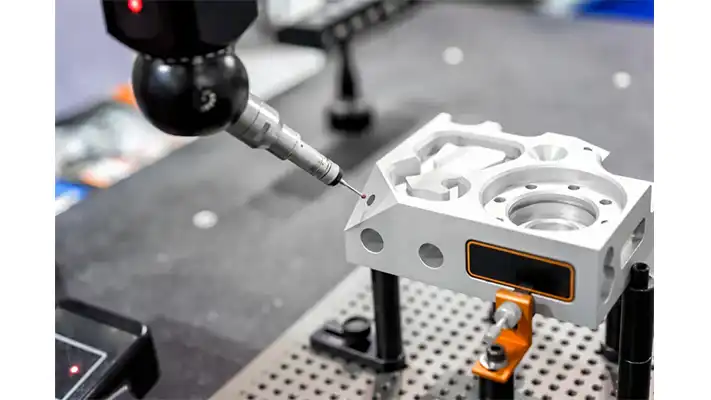

Encoder used in the Robotic Arm for Precise Inspection.

● AI-Enhanced Encoder Signal Processing

Modern encoders are increasingly paired with advanced signal-processing techniques. The predictive filtering and noise compensation improve measurement accuracy in electrically noisy or high-dynamic environments. Integration of microcontrollers with machine learning (ML) algorithms enables real-time error correction, adaptive calibration, and early detection of mechanical wear or misalignment.

● Integrated Encoder-Motor Architectures

There is a growing shift toward frameless motors with embedded encoder sensors, reducing mechanical stack-up and simplifying system assembly. Integrated encoder-motor designs offer a lower system footprint, improved stiffness, and better thermal behavior — key advantages for robotics, cobots, and compact automation systems.

● Higher-Speed Interfaces & Miniaturization

Demand for faster control loops is driving the adoption of high-speed digital interfaces such as BiSS-2 and high-speed SPI. At the same time, encoders are becoming smaller and lighter, with sub-10 mm kit encoder modules enabling high-resolution feedback in space-constrained designs.

● Increasing Shift Toward Inductive & Magnetic Designs

Industrial users increasingly favor magnetic and inductive encoders over optical alternatives due to their durability, EMI immunity, and long-term reliability. This trend reflects the need for robust feedback solutions capable of operating in harsh, real-world environments without sacrificing performance.

Conclusion

Encoders are a foundational element of modern motion control systems, enabling accurate measurement of position, speed, and direction across a wide range of applications.

In this guide, we explored how encoders work, reviewed the different types of encoders based on sensing technology, structure, and signal output, and examined their role in improving precision, stability, and efficiency in automated systems.

In this industrial era, magnetic and inductive encoders are gaining preference due to their robustness, EMI resistance, and reliability in harsh environments where traditional optical solutions may fall short. These technologies are particularly well-suited for robotics, motor control, and industrial automation.

Mosrac plays a key role in this evolving landscape by delivering high-precision encoder solutions engineered for performance, durability, and seamless integration with advanced motion systems.

Explore Mosrac's encoder portfolio or request a custom-engineered solution for your robotics or automation project.

Frequently Asked Questions (FAQs)

Q. What is an encoder used for in motion control systems?

A. The encoder provides real-time feedback on position, speed, and direction, enabling precise closed-loop control in motors, robotics, automation equipment, and industrial motion systems.

Q. What is the difference between an absolute encoder and an incremental encoder?

A. An absolute encoder outputs a unique position value even after power loss, while an incremental encoder generates pulses that must be counted to determine position.

Q. Why are magnetic and inductive encoders preferred in industrial environments?

A. The magnetic and inductive encoders resist dust, oil, vibration, temperature extremes, and EMI, making them more reliable than optical encoders in harsh industrial conditions.

Q. How do encoders improve BLDC and servo motor performance?

A. Encoders enable accurate rotor position feedback, reducing commutation error, improving torque control, increasing efficiency, and ensuring stable operation in BLDC and servo motors.

Q. How do I choose the right encoder for my application?

A. Select an encoder based on application requirements, environmental conditions, sensing technology, interface compatibility, and key specifications such as resolution, accuracy, speed, and durability.