Planetary integrated robot joint module

A Planetary Integrated Joint Module is a compact and efficient actuator that combines a torquemotor, planetary gearbox, and servo driver in one unit. It delivers strong torque while making it ideal for many types of robotic motion systems.

Learn about torque, precision, andintegration options to improve motion control performance. Perfect for engineers looking forefficient robot joint solutions.

Product selection of planetary integrated joint module

Mosrac provides high-performance planetary joint modules with a range of sizes and torque outputs. The products are categorized into standard and custom types, fully satisfying the different application needs of various users.

| Model | Rated Torque(nm) | Peak Torque(nm) | No-load speed(rpm) | Rated Speed(rpm) | Reduction Ratio | Motor size(mm) | Weight(g) | Rated Power(w) | ||||||||

| A3507-2ec | 0.8 | 3 | 460 | 150 | 7 | 46*37.9 | About 150 | 12 | ||||||||

| A3507-2ec/48v | 0.8 | 3 | 900 | 150 | 7 | 46*37.9 | About 150 | 12 | ||||||||

| A4310-2ec v1.1 | 3 | 7 | 200 | 120 | 10 | 57*46 | About 300 | 37 | ||||||||

| A4310-2ec v1.1/48v | 3 | 7 | 400 | 120 | 10 | 57*46 | About 300 | 37 | ||||||||

| A4340-2ec | 9 | 27 | 52.5 | 36 | 40 | 57*53.3 | About 362 | 33 | ||||||||

| A4340-2ec/48v | 9 | 27 | 100 | 36 | 40 | 57*53.3 | About 362 | 33 | ||||||||

| A4340P-2ec | 9 | 27 | 52.5 | 36 | 40 | 57*56.5 | About 375 | 33 | ||||||||

| A4340P-2ec/48v | 9 | 27 | 100 | 36 | 40 | 57*56.5 | About 375 | 33 | ||||||||

| A6006-2ec | 4 | 11 | 226@24v 408@48v | 150 | 6 | 76*36.5 | About 335 | 62 | ||||||||

| A6248P-2ec | 30 | 97 | 60 | 40 | 48 | 76*62.5 | About 628 | 125 | ||||||||

| A8006-2ec v1.1 | 8 | 20 | 194.2@24v 392.8@48v | 120 | 6 | 96*40 | About 559 | 100 | ||||||||

| A8009-2ec | 20 | 40 | 168@24v 335@48v | 100@24v 200@48v | 9 | 98*61.7 | About 896 | 209 | ||||||||

| A8009P-2ec | 20 | 40 | 168@24v 335@48v | 100@24v 200@48v | 9 | 98*61.7 | About 921 | 209 | ||||||||

| A10010-2ec | 40 | 150 | 75@24v 150@48v | 50@24v 100@48v | 10 | 112*62 maximum size:120 | About 896 | 418 | ||||||||

| A10010L-2ec | 40 | 120 | 100@24v 200@48v | 70@24v 100@48v | 10 | 120*53 HWP | About 1375 | 418 | ||||||||

Part no. description

Joint Module

Default: 24V Driver

48V: 48V Driver

V1.0: Version 1.0, default

VX.X: X represents 0-9,

indicating the module upgrade version

Default: single encoder

1ec: single encoder, can communication

2ec: Dual encoders (single-turn

absolute position on output

shaft), can communication

1ee : Single encoder, ethercat

communication 2ee: Dual encoders

(singleturn absolute

position on output shaft),

Ethercat communication

X represents letters

such as L,P,etc. default: deep

Groove ball bearing

P: Cross roller bearing

L: Lite version,not

representing bearing type

06、07、09、10、19、40、48

35、43、60、62、80、100(mm)

A:joint module Series

Feature Description:

| Pole pair identification | Line sequence adaptation |

One-click identification of motor parameters | Dual temperature protection |

Load Adaptation |

| Automatically identify and configure the number of pole pairsforeasy debugging | Automatically identify phase lines to ensure safe debugging and avoid the risk of motor burnout due to incorrect connection and debugging. | Automatically identify phase resistance,phase inductance,flux linkage, and moment of inertia motor parameters,and automatically adjust controller parameters. | Motor +drivedual temperature protection design,safer! | It senses the load and automatically adjusts controller parameters to maintain optimal equipment operation. |

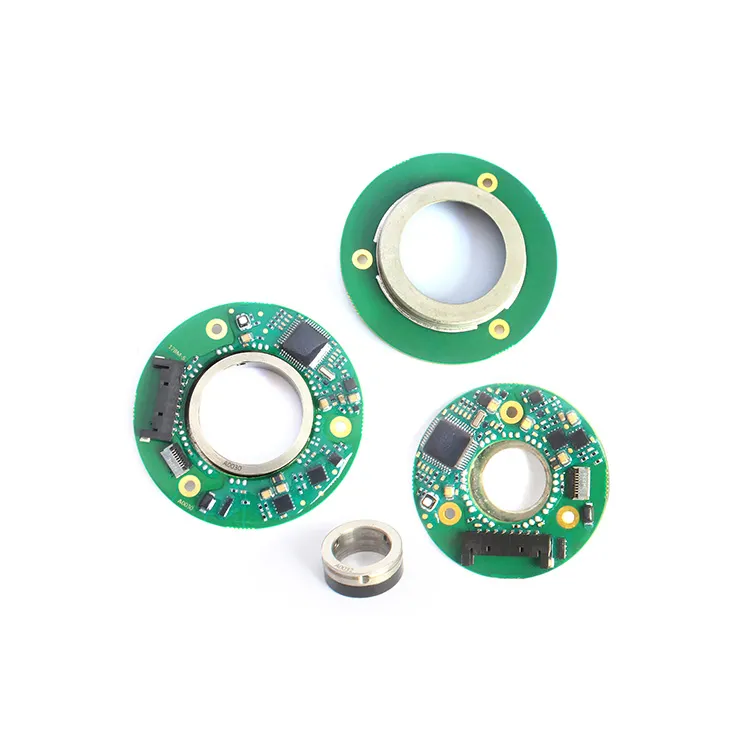

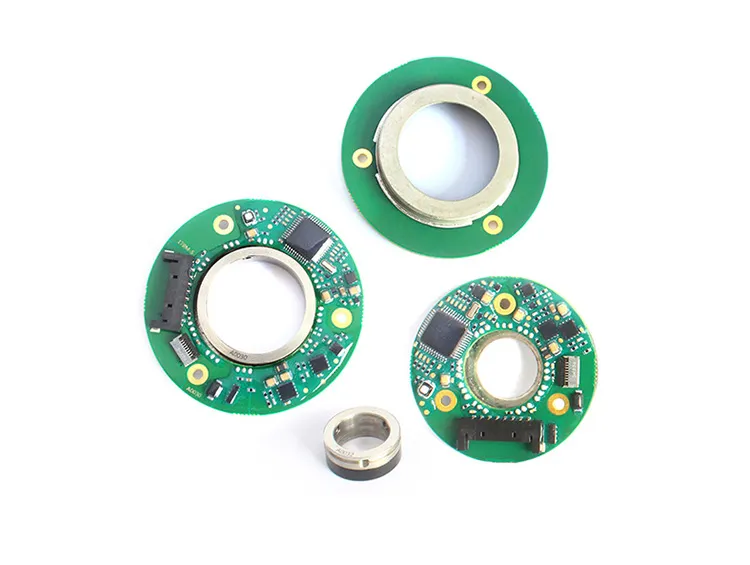

Frequently bought together - Magnetic encoders

Direct drives need high-quality position signals to ensure optimal performance. Perfect measuring signals can enhance the surface quality of machined workpieces, reduce the machine frame's vibrations, minimize velocity-dependent motor noise, and prevent excessive heat generation in the motor.

Mosrac recommends using a magnetic encoder to enhance the accuracy, speed stability, and thermal behavior of direct drive axes. Because there is no mechanical transmission between the encoder and the feed unit, the position signals are not susceptible to inaccuracies or delays.

Custom combinations are available on request and contact us.

-

Frameless Inrunner Motor

-

Frameless Outrunner Motor

-

Inductive Encoder

-

Magnetic Encoders

-

Cycloidal RV Reducers

-

Planetary Joint Module