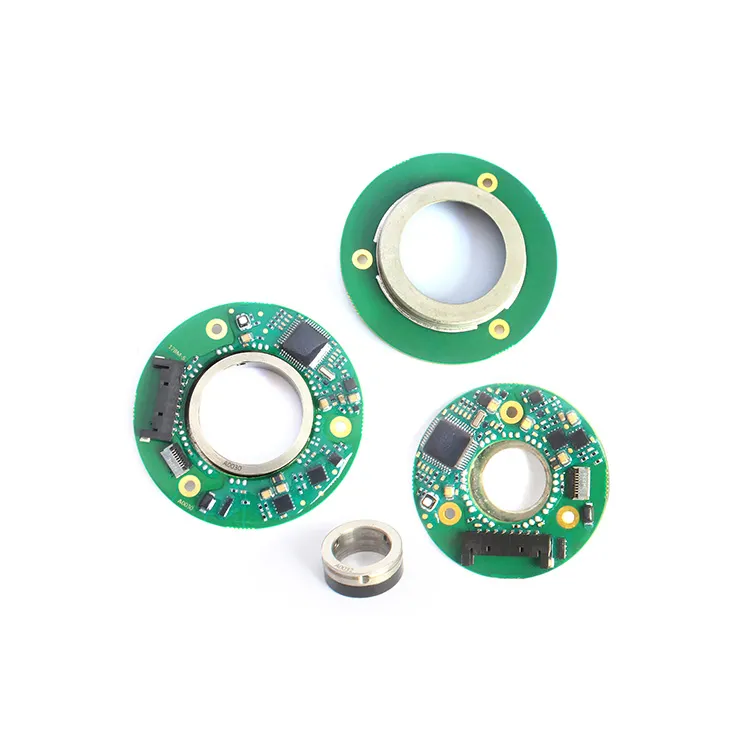

PT-Series Magnetic EncoderUltral-compact design, 24-bit absolute output, ±0.01° accuracy

Comparison Table of PT Series Magnetic Encoder

The PT series is driven by magnetoelectric technology and has a unique interference shielding technology. There are multiple high-precision magnetic field sensors inside the encoder to measure the field strength changes of the rotor magnetic ring, which is formed by the precision calibration technology.

| Types | Rotor style | Stator style | lnner rotor thread | Rotor Match OD(H7)A/B/C | Stator Match OD(H7) | Stator installation pitch circle | The stator can be back installed directly⑵ | Connector Models | Overall thickness | |

| PT-10-20 PT-10B-20 PT-10-20H PT-10B-20H |

Thread Bonding Thread Bonding |

Front install Front install Front and back install Front and back install |

M10x0.4mm - M10x0.4mm - |

9 9/10/12.6 9 9/10/12.6 |

20 | 16.6 | - - ✔ ✔ |

SM06B-XSRS-ETB | 6.7 | |

| PT-13-25 PT-13-25H PT-14-25 PT-14-25H PT-15-25 PT-15B-25 PT-15-25H PT-15B-25H |

Thread Thread Thread Thread Thread Bonding Thread Bonding |

Front install Front and back install Front install Front and back install Front install Front install Front and back install Front and back install |

M13x0.4mm M13x0.4mm M14x0.4mm M14x0.4mm M15x0.4mm - M15x0.4mm - |

12 12 13 13 14 14/15/17.6 14 14/15/17.6 |

25 | 21.6 | - ✔ - ✔ - - ✔ ✔ |

SM06B-XSRS-ETB | 6.7 | |

| PT-20-30 PT-20B-30 PT-20-30H PT-20B-30H |

Thread Bonding Thread Bonding |

Front install Front install Front and back install Front and back install |

M20x0.4mm - M20x0.4mm - |

19 19/20/22.6 19 19/20/22.6 |

30 | 26.6 | - - ✔ ✔ |

SM08-SURS-TF | 6.7 | |

| PT-25-35 PT-25B-35 PT-25-35H PT-25B-35H |

Thread Bonding Thread Bonding |

Front install Front install Front and back install Front and back install |

M25x0.4mm - M25x0.4mm - |

24 24/25/27.6 24 24/25/27.6 |

35 | 31.6 | - - ✔ ✔ |

SM08-SURS-TF | 6.7 | |

| PT-30-40 PT-30B-40 PT-30-40H PT-30B-40H |

Thread Bonding Thread Bonding |

Front install Front install Front and back install Front and back install |

M30x0.4mm - M30x0.4mm - |

29 29/30/32.6 29 29/30/32.6 |

40 | 36.6 | - - ✔ ✔ |

SM08-SURS-TF | 6.7 | |

| PT-35-45 PT-35B-45 PT-35-45H PT-35B-45H |

Thread Bonding Thread Bonding |

Front install Front install Front and back install Front and back install |

M35x0.4mm - M35x0.4mm - |

34 34/35/37.6 34 34/35/37.6 |

45 | 41.6 | - - ✔ ✔ |

SM08-SURS-TF | 6.7 | |

Drawing

When installing the stator, can use an M1.6 screw to pass through the M2 threaded hole or can use an M2 thread with an M2 screw to lock it.

When installing the rotor use a special tool to tighten it

Part no. description

PT Series Magnetic Encoder

M-no addition Baud

rate-when the

interface is R , A

A – -40~85°C

B – -40~105°C

C – -40~125°C

(compact models supports only)

N–5V

S–SSI (1)

B–BISS-C

R–RS485

A – RS422

T–T485 (compatible with 17-bit Tamagawa) (2)

T–T485 (compatible with 23-bit Tamagawa) (2)

D–BUS (high-speed bus)

P–PERIOD (periodic sending)

24–24-bit single turn

A-absolute

Refer to Size

XX-Thread type

XXB-Bonding type

Refer to Size

XX-Thread type

XXB-Bonding type

24M - 24-bit single turn + normal multi turn

Multi-turn clear after power failure Multi-turn only valid when power on

24BM - 24-bit single turn + battery multi turn

After power failure, it can still maintain multi-turn measurement by using battery power

24FM - 24-bit single turn + flash multi turn

Only ±90° rotation is allowed after power failure No battery required

The SSI protocol does not have CRC check. It is recommended to use BISS-C with the same hardware to improve reliability.

When the Tamagawa protocol selects 17 bits, the output parameters are 17M-T, 17BM-T, and 17FM-T.When 23 bits are selected, the output parameters are 23M-T, 23BM-T, and 23FM-T.

Download

Parameters

| System | |

| Installation method | Axial hollow |

| Accuracy | ±0.01° |

| Electrical | |

| Power supply | 4.5 ~ 5.5 V |

| Battery | 2.7 ~ 3.6 V |

| Start-up time | 15 ms |

| Connection method | Wire-to-board connector |

| Current | ≈ 100 mA |

| Low power consumption current | ≈6 μA (battery voltage 3.6V, in low power static detection mode) |

| ESD resistance | HBM,max. ±2 kV CDM,max. ±1 kV |

| Mechanical | |

| rotor bracket | Stainless steel |

| Stator bracket | Aluminum alloy |

| Environmental | |

| Operating temperature | -40 ~ 85 °C / -40 ~ 105 °C / -40 ~ 125 °C |

Frequently bought together - Torque motors

The U-series, FE series, and FI series stator-rotor kits represent Mosrac's consistent evolution of the previous generation's torque motor series. Delivering excellent overload capabilities, high torque density, and maximum precision, these kits are built to fit seamlessly into compact spaces. They are widely used for demanding applications such as medical technology, robotics, mechanical engineering, tools, etc.