Overview of inductive rotary absolute encoders

An absolute encoder of the highest quality in as small a size as possible.

Mosrac's absolute rotary encoder uses inductive technology, featuring a hollow shaft, high precision, high reliability, and non-contact. Our inductive rotary absolute encoders are compact, reliable, and precise, designed for tight spaces and precision motion control with advanced magnetic resistance and high accuracy.

Featuring an ultra-lightweight, flat design, the absolute inductive rotary encoder fits and operates wherever it is needed, including aerospace and defense, harsh environments, and industrial, medical, robotics, servo BLDC motors, cobots & robotic joints, and automotive applications.

C-Series Inductive Rotary Encoders

Ultra-thin and lightweight, with a large hollow shaft and non-contact design — ideal for compact applications with limited space. It can be seamlessly installed in robot joints or multi-axis automation equipment. The encoder is suitable for position feedback or improving commutation in frameless motors.

The non-contact absolute C-series encoder meets stringent industrial environment standards and offers a cost-effective, accurate, and reliable position sensing solution; customization options are available.

| Model | OD (mm) | ID (mm) | Thickness (mm) | Weight (g) | Resolution (bit) | Accuracy (°) | Max.speed (rpm) | Moment of Inertia (kg·mm²) | ||||||

| C0214 | 14.8 | 2 | 3.6 | 2 | 15~17 | ±0.03 | 6000 | 0.006 | ||||||

| C0216 | 16.8 | 2 | 3.6 | 2.5 | 15~17 | ±0.025 | 6000 | 0.008 | ||||||

| C0218 | 18.8 | 2 | 3.6 | 3 | 15~17 | ±0.02 | 6000 | 0.01 | ||||||

| C0420 | 20 | 4 | 6.5 | 4 | 15~17 | ±0.05 | 4000 | 0.01 | ||||||

| C1040 | 40 | 10 | 8 | 10 | 17~19 | ±0.015 | 6000 | 0.4 | ||||||

| C1752 | 52 | 17 | 7.6 | 13 | 18~20 | ±0.01 | 8000 | 1.18 | ||||||

| C2560 | 60 | 25 | 8 | 18 | 18~20 | ±0.008 | 8000 | 2.43 | ||||||

| C3580 | 80 | 35 | 8 | 30 | 18~20 | ±0.008 | 8000 | 8.6 | ||||||

| C48100 | 100 | 48 | 8 | 40 | 19~21 | ±0.006 | 6000 | 19.7 | ||||||

| C70120 | 120 | 70 | 8 | 50 | 19~21 | ±0.006 | 6000 | 40 | ||||||

| C90140 | 140 | 90 | 9 | 75 | 19~21 | ±0.006 | 6000 | 99 | ||||||

| C120180 | 180 | 120 | 9 | 120 | 20~22 | ±0.003 | 4000 | 239.2 | ||||||

| C172247 | 247 | 172 | 9 | 180 | 20~22 | ±0.003 | 4000 | 795.6 | ||||||

| Supply voltage | Elec. Conn. | Output protocol | Operating Temp | Max. IP Grade | |

| 5-30V | RS-422 Shielded cable | SSi、BiSS-C、RS-422 UART | -20℃ - +60℃ | IP 40 | |

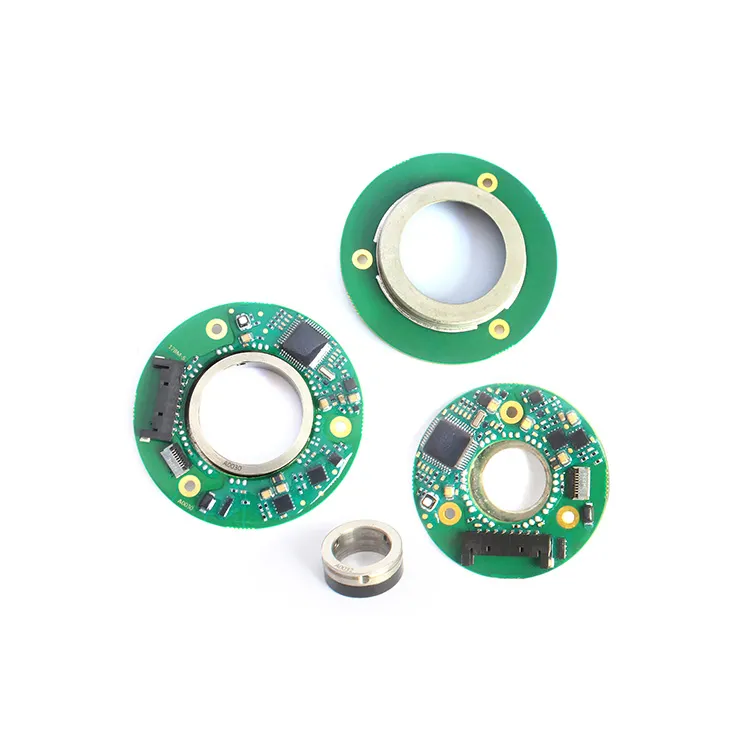

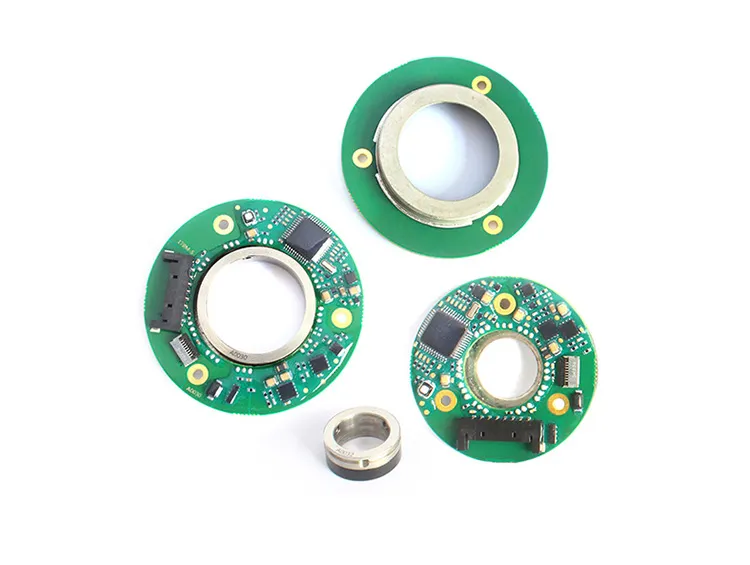

D-Series Inductive Rotary Encoders

The product includes three parts: a stator and two rotors.

It is perfect for compact applications where space is tight and can be easily installed in robot joints or multi-axis automation systems.

The D-series encoder has two separate position-detection and signal-output systems, allowing for redundant operation and greatly increasing reliability.

Customization options are available to best suit customer needs.

| Model | OD(mm) | ID(mm) | Thickness(mm) | Weight(g) | Resolution(bit) | Accuracy(°) | Max.speed(rpm) | Moment of Inertia(kg·mm²) | ||||||

| D1034 | 34 | 10 | 7.6 | 10 | 17~19 | ±0.015 | 6000 | 0.11 | ||||||

| D2050 | 50 | 20 | 7.6 | 20 | 17~19 | ±0.015 | 6000 | 0.7 | ||||||

| D2158 | 58 | 18-21 | 7.6 | 30 | 18~20 | ±0.01 | 6000 | 1.66/1.58 | ||||||

| D3670 | 70 | 36 | 7.6 | 35 | 18~20 | ±0.01 | 6000 | 3.4 | ||||||

| D3178 | 78 | 31-35 | 7.6 | 40 | 18~20 | ±0.01 | 6000 | 4.5/4.3 | ||||||

| D5690 | 90 | 56 | 7.6 | 50 | 19~21 | ±0.01 | 6000 | 9.8 | ||||||

| D76110 | 110 | 76 | 7.6 | 65 | 19~21 | ±0.01 | 6000 | 21.2 | ||||||

| Supply voltage | Current | Output protocol | Operating Temp | Max. IP Grade | |

| 5-24V | <240 mA | SSi、BiSS-C、RS-422、RS-485、UART、ABZ | -20℃ - +60℃ | IP 40 | |

DP-Series Inductive Rotary Encoders

The DP-series encoders consist of a single stator and an inner and outer dual rotor. It uses electromagnetic fields and recognition technology to implement a dual-encoder design on one side within an ultra-thin, narrow form factor. It features high precision, low power consumption, and an ultra-thin, compact structure.

The DP dual encoder on one side features two independent detection and signal output systems, making it ideal for robot joints or multi-axis automation equipment with limited space.

Customization options are ideally available to meet customer needs.

| Model | OD(mm) | ID(mm) | Thickness(mm) | Weight(g) | Resolution(bit) | Accuracy(°) | Max.speed(rpm) | Moment of Inertia(kg·mm²) | ||||||

| DP1038 | 38 | 10 | 3.6 | 10 | 17~19 | ±0.015 | 6000 | 0.05/0.16 | ||||||

| DP1646 | 46 | 16 | 3.6 | 12 | 17~19 | ±0.015 | 6000 | 0.17/0.4 | ||||||

| DP2055 | 55 | 20 | 3.6 | 16 | 17~19 | ±0.015 | 6000 | 0.36/1.0 | ||||||

| DP3065 | 65 | 30 | 3.6 | 20 | 18~20 | ±0.01 | 6000 | 0.88/2.06 | ||||||

| DP3575 | 75 | 35 | 3.6 | 25 | 18~20 | ±0.01 | 6000 | 1.84/3.95 | ||||||

| DP4585 | 85 | 45 | 3.6 | 30 | 18~20 | ±0.01 | 6000 | 3.4/6.33 | ||||||

| DP55100 | 100 | 55 | 4 | 45 | 19~21 | ±0.01 | 6000 | 6.54/13.5 | ||||||

| DP85130 | 130 | 85 | 4 | 60 | 19~21 | ±0.01 | 6000 | 6.54/13.5 | ||||||

| Supply voltage | Current | Output protocol | Operating Temp | Max. IP Grade | |

| 5V | <80 mA | SSi、BiSS-C、RS-422、RS-485 | -30℃ - +100℃ | IP 40 | |

Features & Benefits:

● Highest performance in the smallest installation space

● Ultra-flat, lightweight, and narrow (minimum thickness 3.6mm)

● Super compact, Frameless design without bearings

● Resistant to electric & magnetic fields

● High accuracy and resolution

● Absolute hollow shaft

● Wide mounting tolerance

Applications:

● Robotics, Cobots, Medical Robots & Robotic Joints

● Direct integration for Servo, BLDC motors

● Stepper motors

● Medical equipment

● Industrial automation

● Metrology

● High-speed motion control

● UAV & Drones, Gimbals

● Stabilized Platforms, Rotary stages

Frequently bought together - Magnetic encoders

Direct drives need high-quality position signals to ensure optimal performance. Perfect measuring signals can enhance the surface quality of machined workpieces, reduce the machine frame's vibrations, minimize velocity-dependent motor noise, and prevent excessive heat generation in the motor.

Mosrac recommends using a magnetic encoder to enhance the accuracy, speed stability, and thermal behavior of direct drive axes. Because there is no mechanical transmission between the encoder and the feed unit, the position signals are not susceptible to inaccuracies or delays.

Custom combinations are available on request and contact us.

-

Frameless Inrunner Motor

-

Frameless Outrunner Motor

-

17-bit S-Series Magnetic Encoders

-

24-bit T-Series Magnetic Dual Encoders

-

PT-Series Magnetic Encoder

-

Planetary Joint Module