Product selection of Frameless Motors for Linear Joints

This high-density, frameless torque motor is specifically designed for integration into humanoid robot linear joints. Its very compact design allows for seamless integration into tight spaces while maintaining structural durability and providing precise, smooth linear movement.

The following highlights the main specifications. Click the "model number" to access technical files, including catalogs, 3D files, and outline drawings for each robot joint motor.

| Model | Max torque(nm) | OD(mm) | Height(mm) | ID(mm) | Rated Torque(Nm) | Peak Torque(nm) | Rated Speed(rpm) | Max Speed(rpm) | Voltage(V) | Weight(kg) | |

| U2527-400 | 400 | 25 | 27 | 11.6 | 0.092 | 0.222 | 6000 | 7500 | 48 | 0.068 | |

| U3834-600 | 600 | 38 | 34.3 | 18 | 0.35 | 1.05 | 3000 | 4500 | 48 | 0.16 | |

| U4672-4000 | 4000 | 46 | 72 | 25 | 1 | 2.8 | 3500 | 6000 | 48 | 0.586 | |

| U5085-6000 | 6000 | 50 | 85 | 30 | 1.75 | 5.25 | 3000 | 4500 | 48 | 0.63 | |

| U6075-8000 | 8000 | 60 | 75 | 33 | 2.5 | 7.5 | 3000 | 4500 | 48 | 0.69 | |

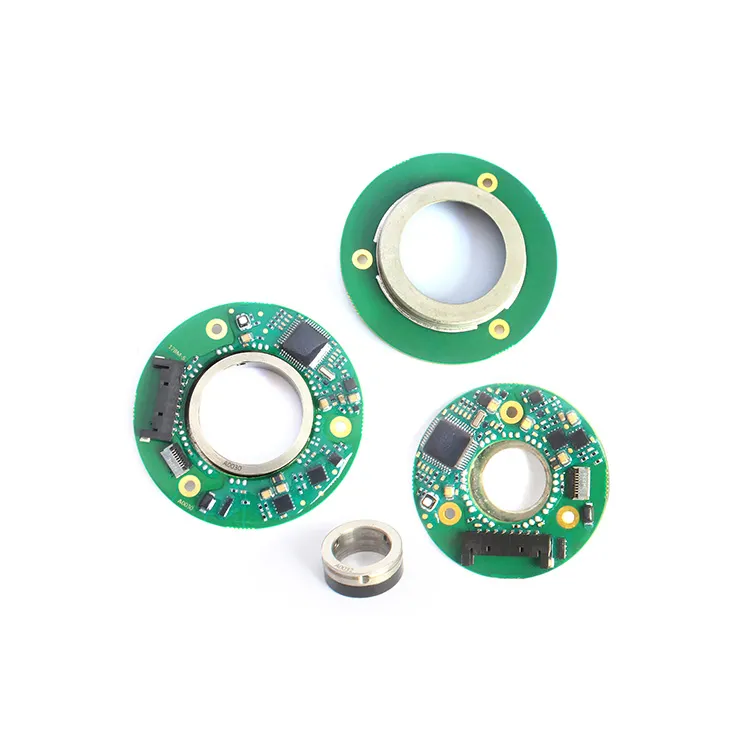

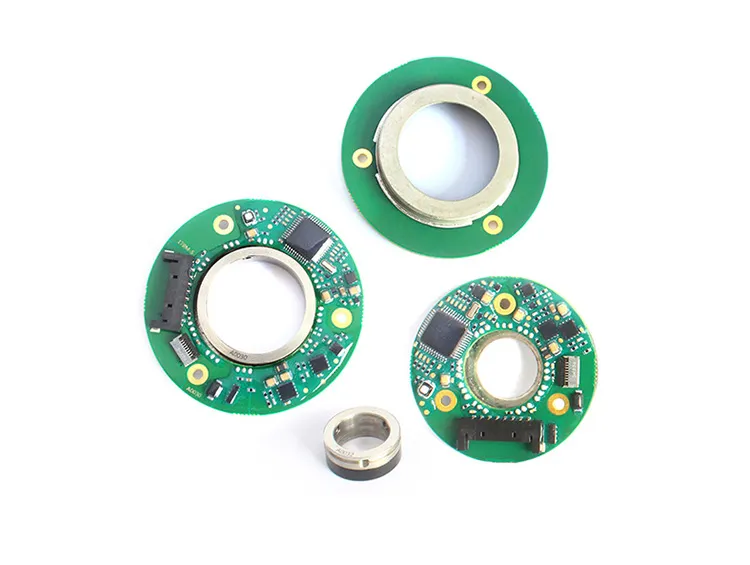

Frequently bought together - Magnetic encoders

Direct drives need high-quality position signals to ensure optimal performance. Perfect measuring signals can enhance the surface quality of machined workpieces, reduce the machine frame's vibrations, minimize velocity-dependent motor noise, and prevent excessive heat generation in the motor.

Mosrac recommends using a magnetic encoder to enhance the accuracy, speed stability, and thermal behavior of direct drive axes. Because there is no mechanical transmission between the encoder and the feed unit, the position signals are not susceptible to inaccuracies or delays.

Custom combinations are available on request and contact us.

-

Frameless Inrunner Motor

-

Frameless Outrunner Motor

-

Inductive Encoder

-

Magnetic Encoders

-

Cycloidal RV Reducers

-

Planetary Joint Module