Custom Quality Torque Motors

Custom direct drive torque motor

tailored to your special application needs

Mosrac’s innovative stator and rotor design, combined with a skilled engineering team, allows standard motors to be customized for specific needs, even in small volumes at a reasonable cost. Custom frameless servomotors help customers gain a competitive advantage. We also developed multiple cooling options and can adjust connectors, shafts, and mounting to improve performance and efficiency.

Mosrac has developed custom motors with our customers for over 10 years, offering a range of shapes and sizes; see some examples below.

Custom Quality Torque Motors

Our dedicated engineering, design, and

sales teams

support you at 8 levels

General custom development stages

1. Gathering and analyzing requirements

Identify the specific needs of your application, such as load requirements, operational environment, space limitations, power, voltage, and performance criteria.

2. Defining the specifications

Defining specifications for customizing direct-drive torque motors involves several key details, including peak and continuous torque, speed, size, etc.

3. Conducting feasibility analysis & study

Conducting a feasibility analysis for customizing direct-drive torque motors involves evaluating technical, financial, market, and risk factors.

4. Concept Eng. & product development

Concept engineering for customizing direct-drive torque motors involves idea generation, concept selection, and preliminary design to explore feasible solutions.

5. Prototyping, testing, and design verification

Prototyping, testing, and design are key steps in frameless motor development. A prototype is built for early evaluation. Testing verifies performance, reliability, and compliance. Design verification ensures the final motor meets all requirements and is ready for mass production.

6. Trial-produce and mass manufacturing

Trial production and mass manufacturing are critical for making frameless motors and involve creating small batches to identify and resolve potential issues, ensuring design integrity and manufacturing processes, and then arranging the mass manufacturing.

7. Customized Packing and safe shipping

Packing and shipping are crucial for delivering frameless motors safely. Proper packing involves using protective materials to prevent damage during transit, selecting reliable logistics partners, and implementing tracking systems to ensure timely, secure delivery.

8. High-Quality Warranty and service

A comprehensive warranty provides assurance against defects and covers repairs or replacements. Excellent service includes responsive customer support, regular maintenance, and readily available parts.

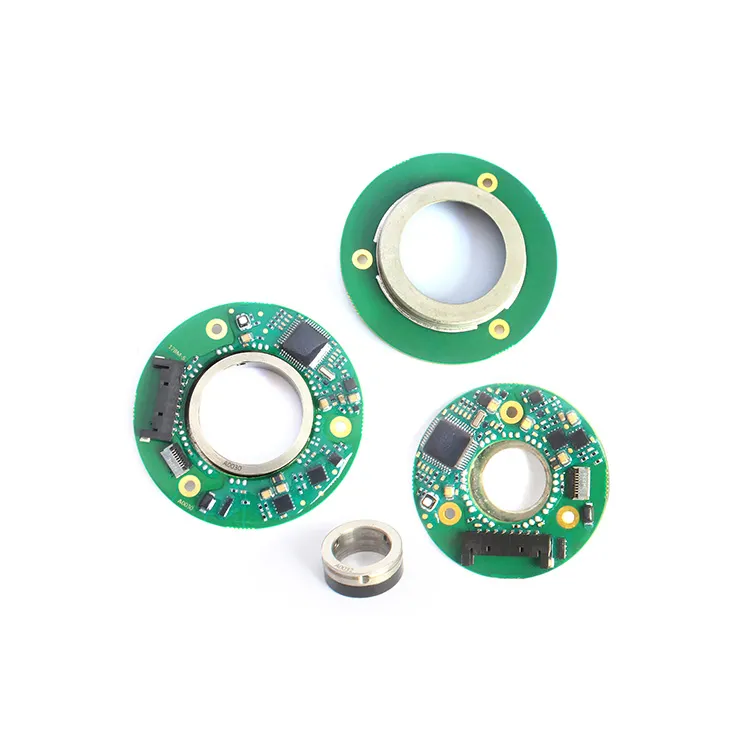

Custom Motors Showcase

Below are some examples of custom frameless servo motors we have designed, prototyped, and built for our clients.

Some of Our Customization Cases

Not sure which torque motor to choose?

- • Expert advice on choosing the best material and structure to meet your needs

- • Professional guidance from engineers and designers on building the best torque motor experience

- • Anytime support with full-cycle project management and proactive updates